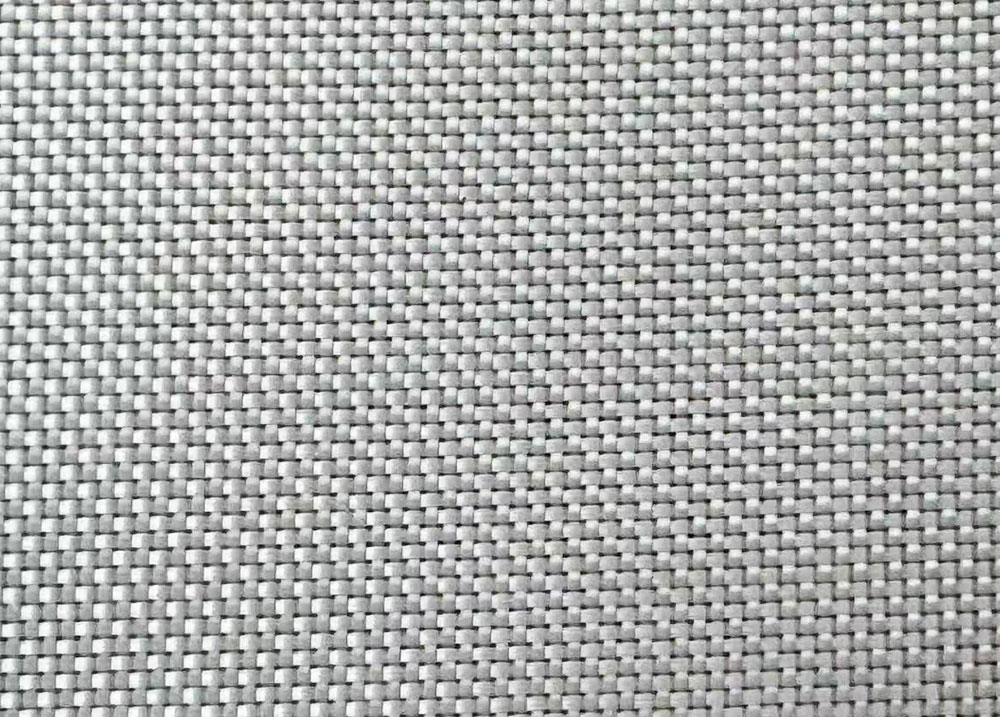

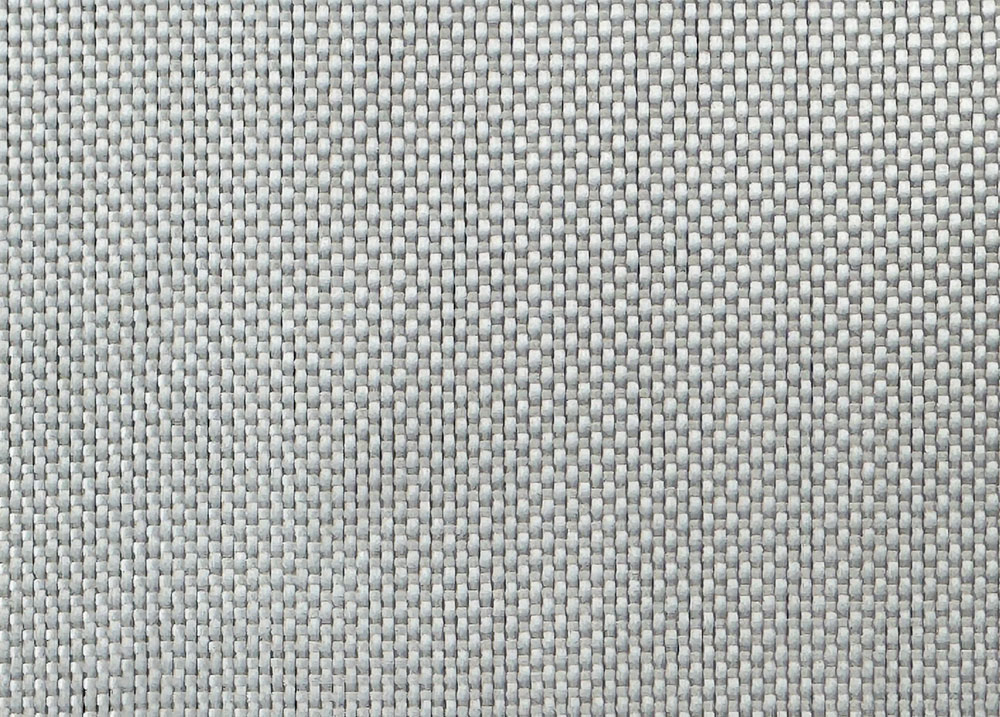

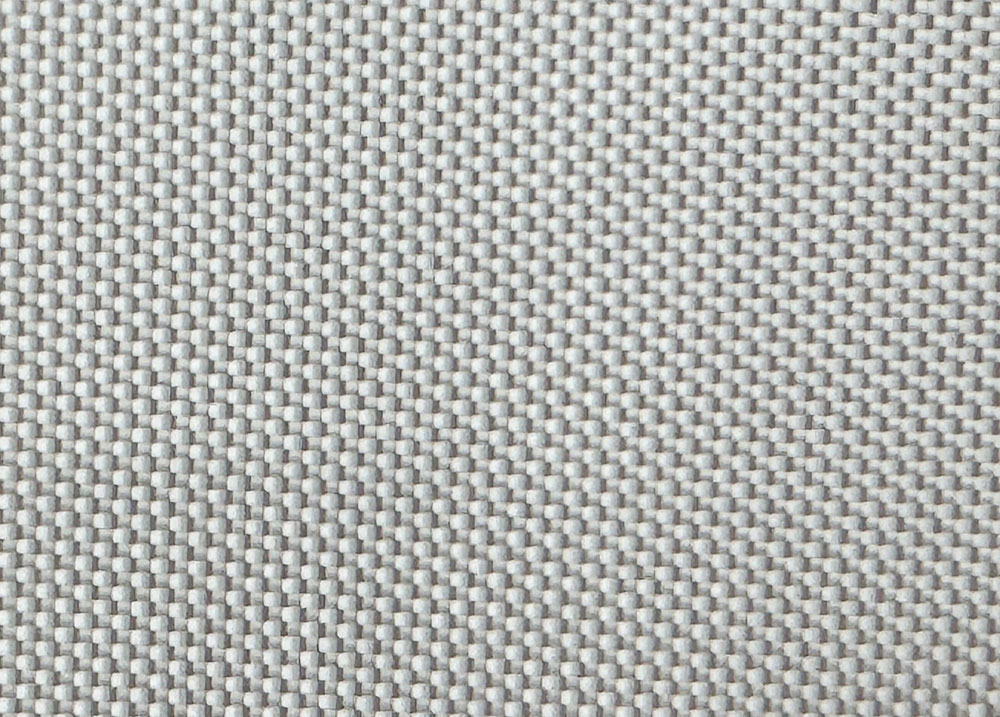

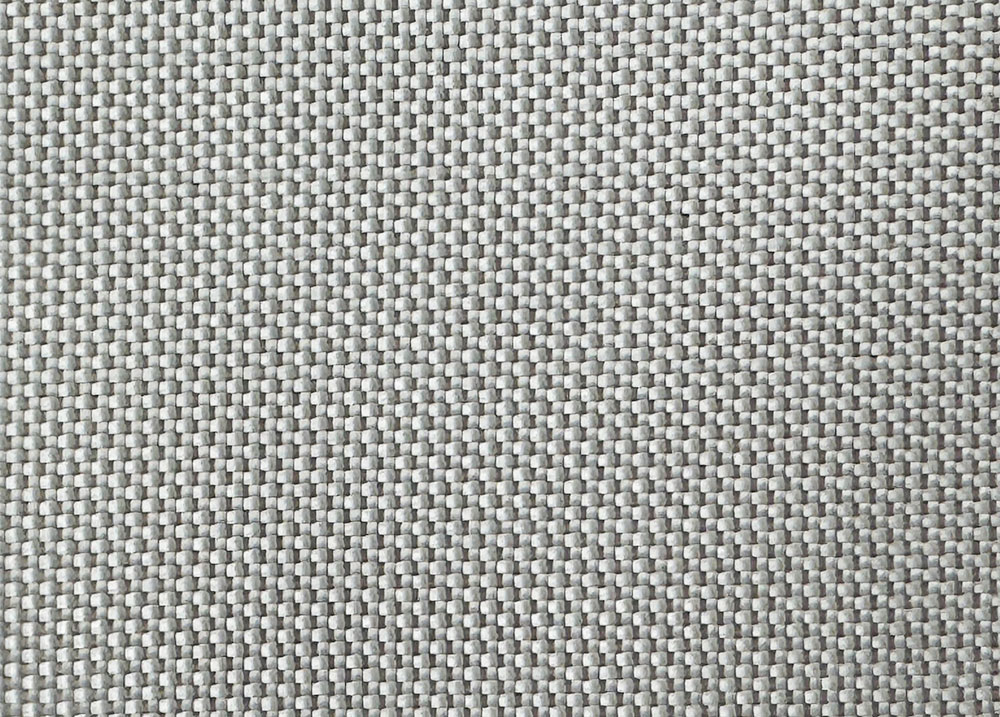

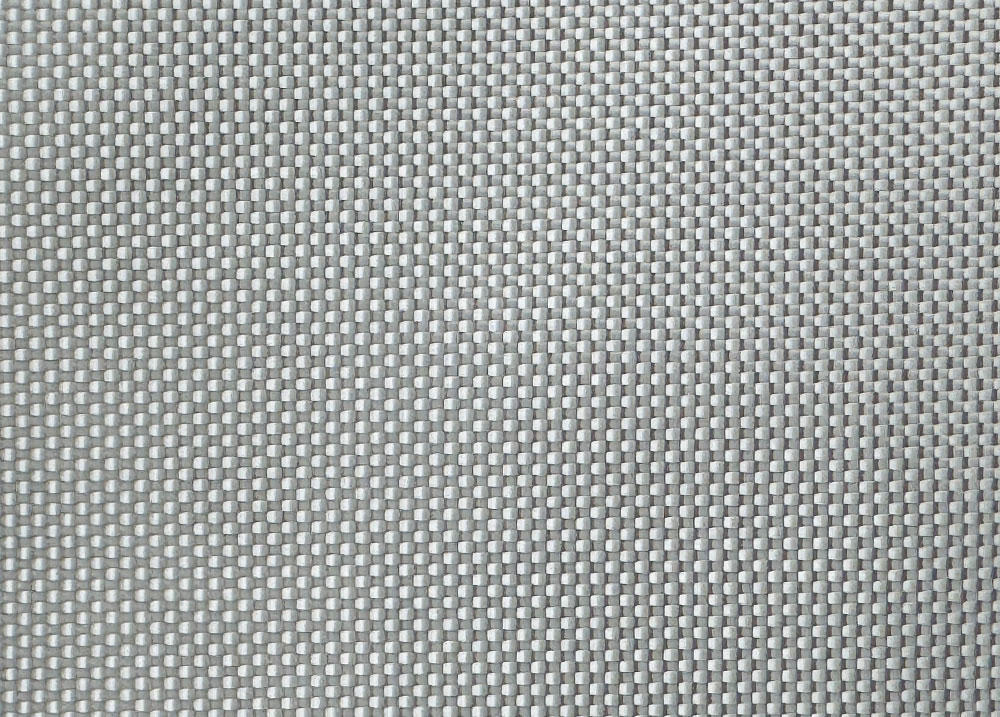

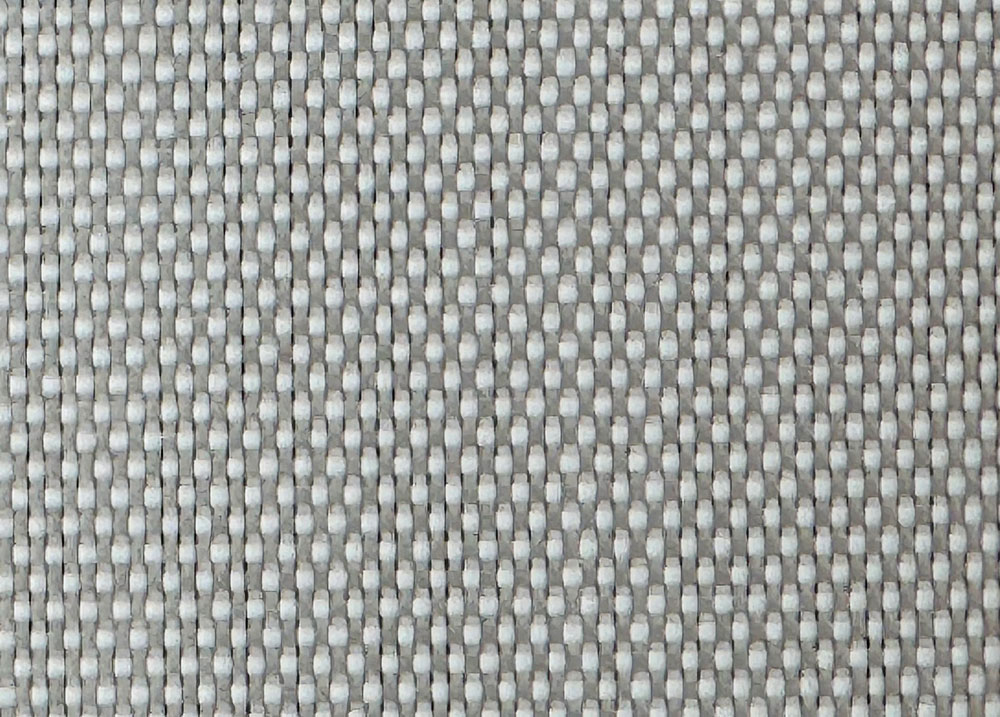

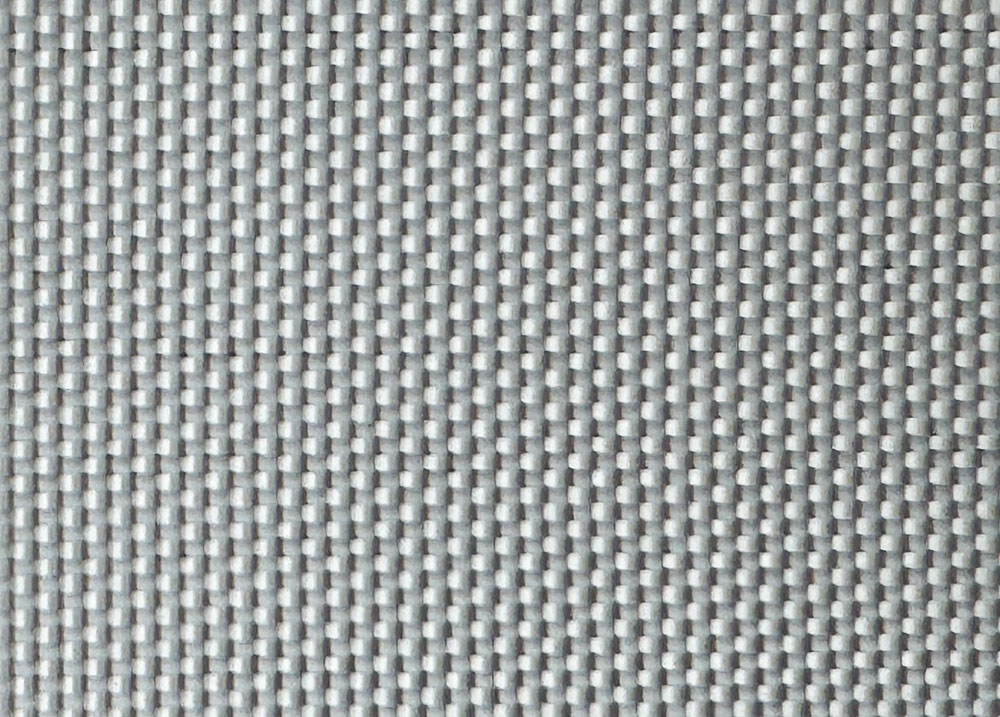

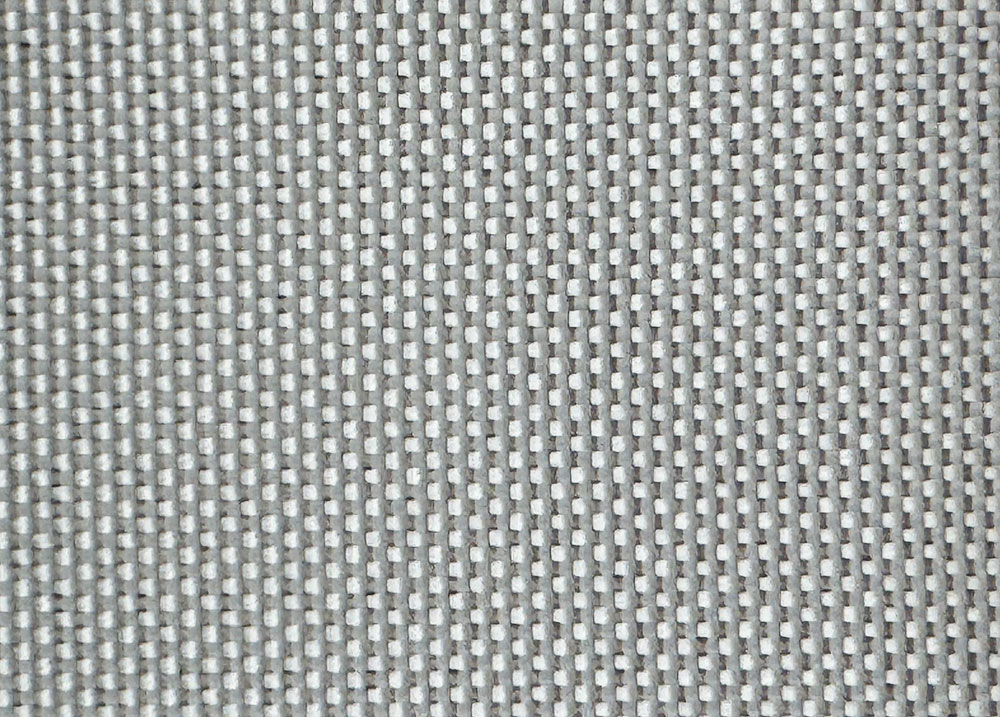

Fiberglass Woven Fabric is a high-performance material made by weaving glass fibers using traditional techniques, interlacing warp and weft yarns. The woven structure enhances the natural properties of glass fibers, such as high strength, heat resistance, and electrical insulation—making it ideal for use as a reinforcement in composites or as a functional barrier in various industries.

Primarily made of silicon dioxide (SiO₂, 50–75%), combined with metal oxides like alumina (Al₂O₃) and calcium oxide (CaO). These are melted and drawn into continuous fibers with diameters ranging from 5 to 24 microns.

· E-glass: General-purpose; excellent insulation and cost-effective.

· S-glass: High strength; 30–40% stronger than E-glass.

· C-glass: Acid-resistant; suited for corrosive environments.

· Yarn Preparation: Raw yarns are twisted or plied (e.g., EC9 67tex) to form weaving yarns.

· Looms Used: · Rapier looms – to minimize fiber damage

· Air-jet looms – for efficient, high-speed production

· Plain Weave: Tight, balanced structure; used in circuit board substrates.

· Twill Weave: More flexible; ideal for contoured parts like boat hulls.

· Satin Weave: Smooth surface; superior resin absorption for aerospace laminates.

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More