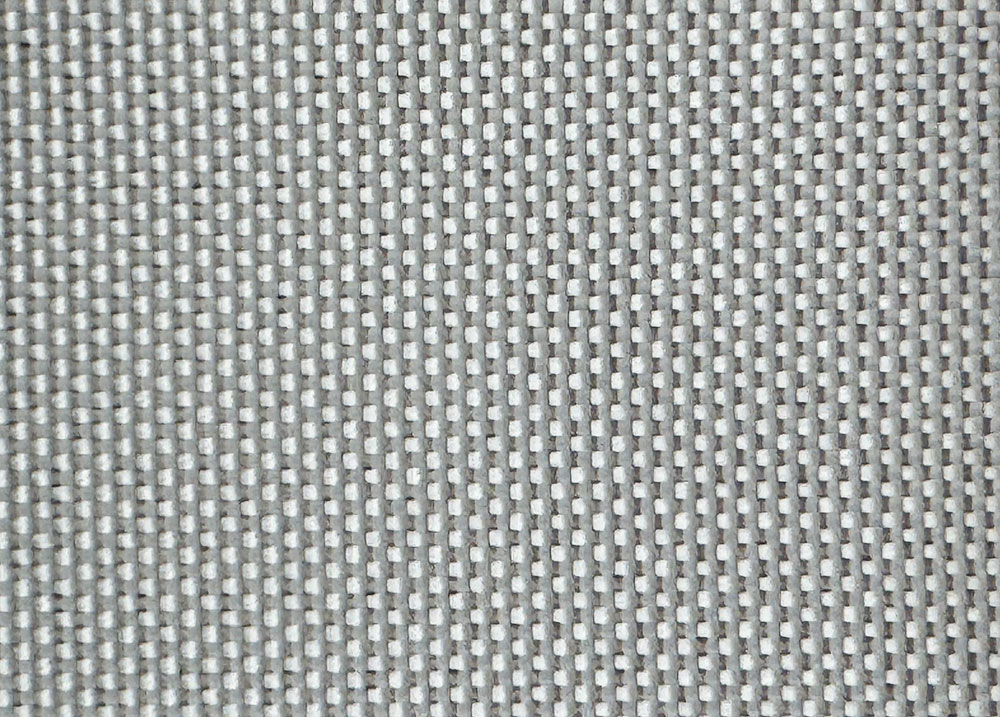

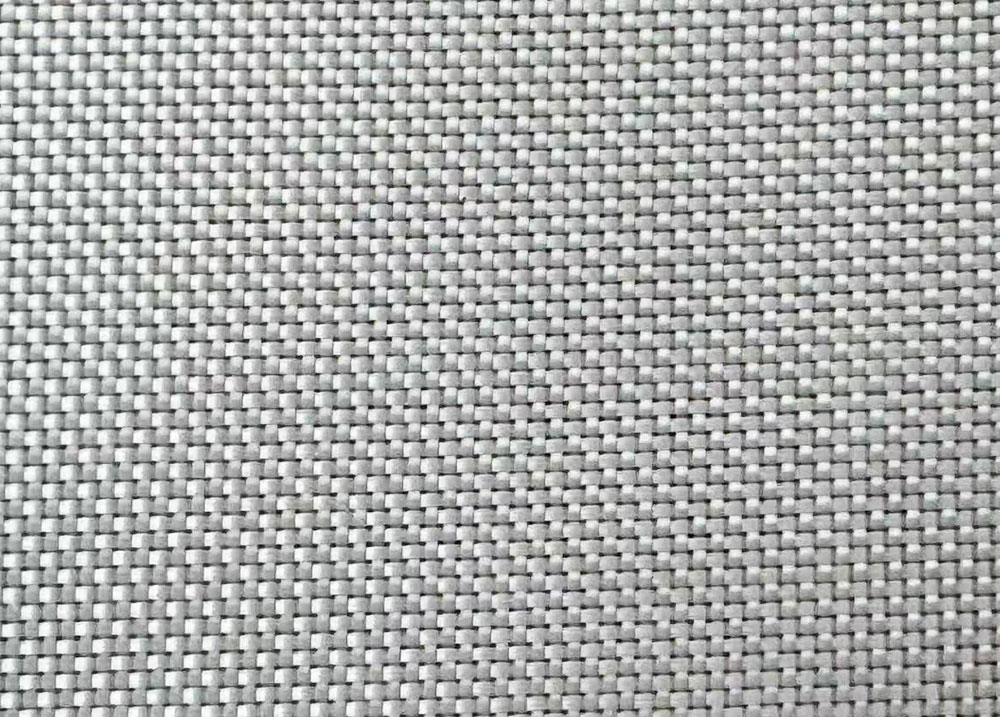

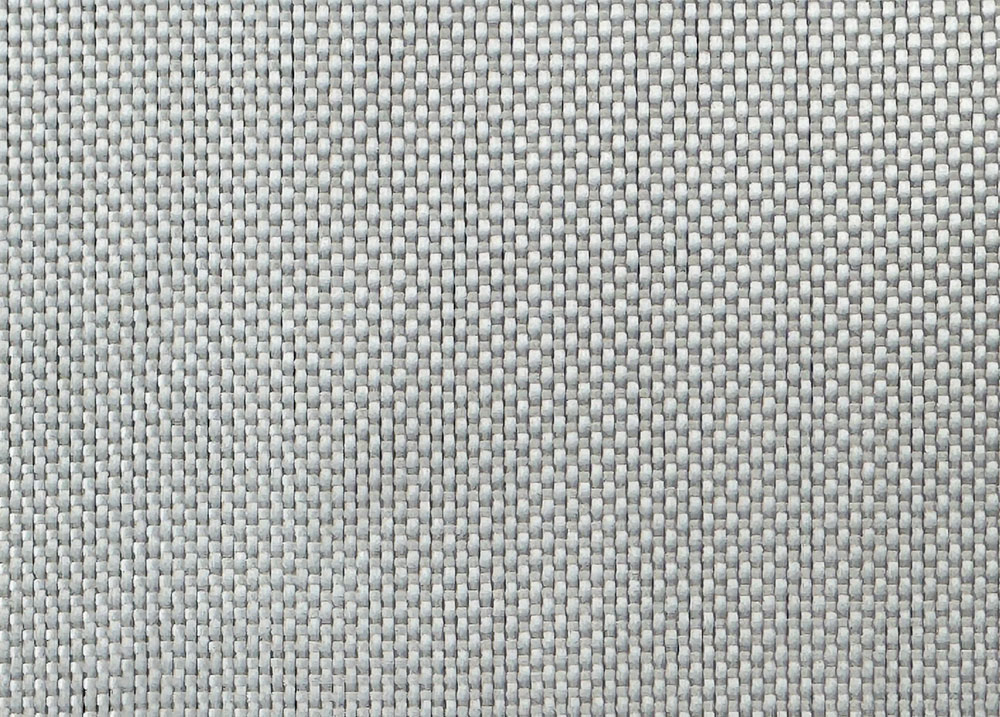

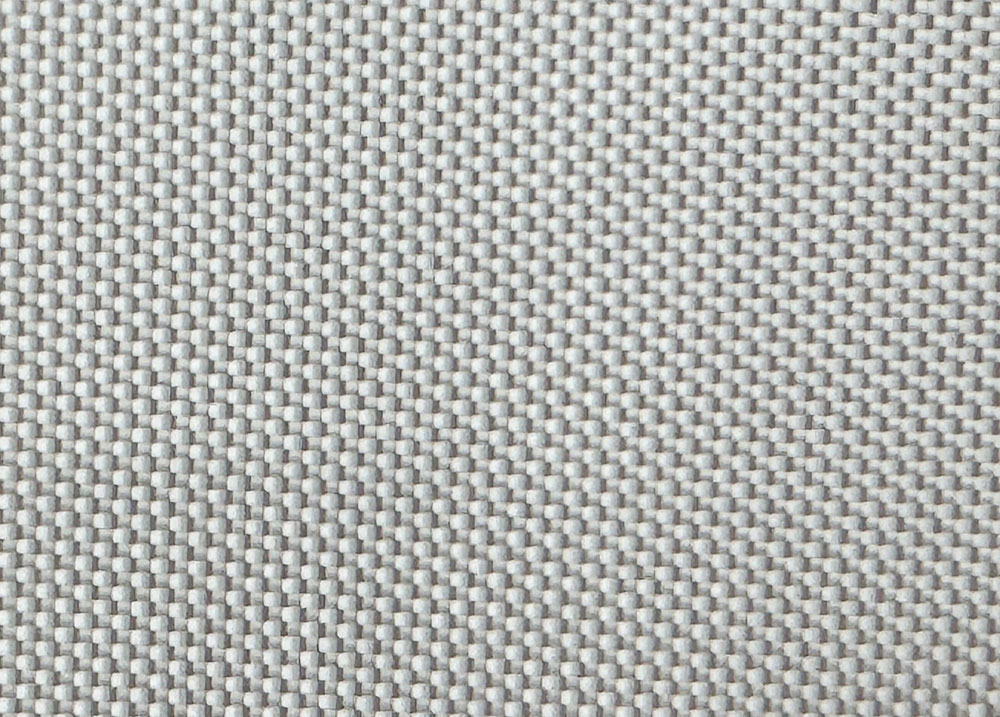

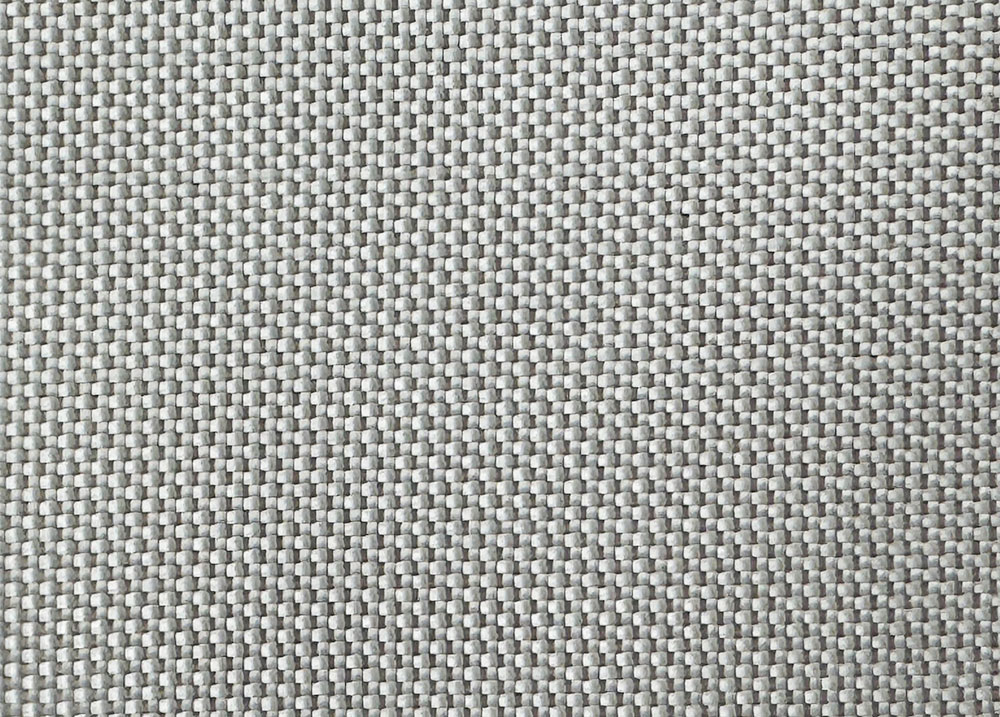

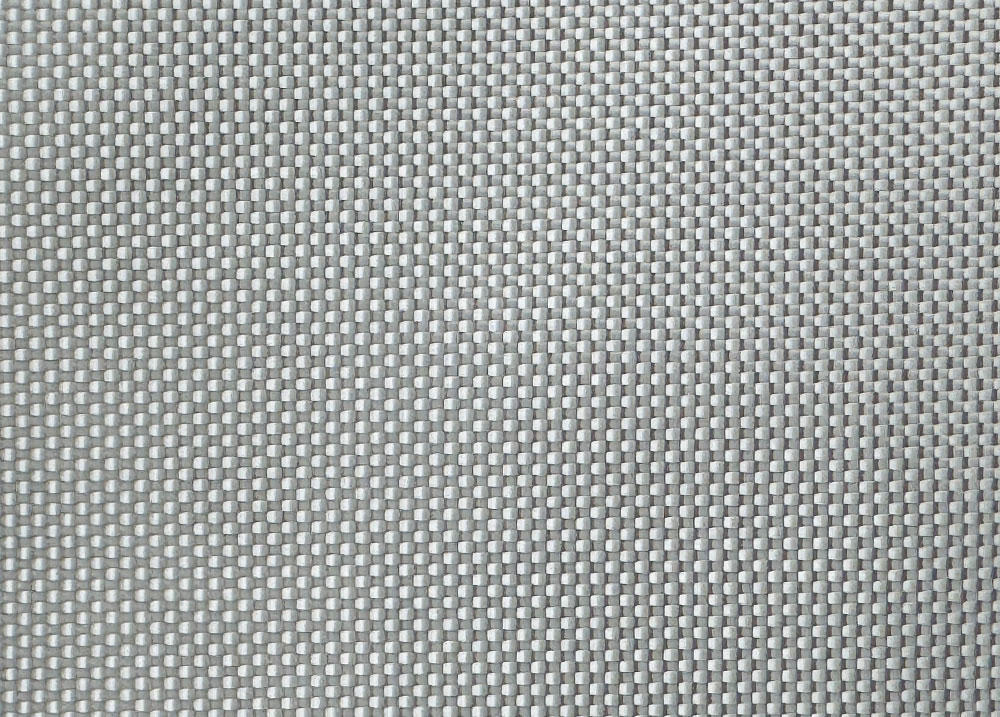

Fiberglass Textile

Key Features

· High thermal protection and durability

· Tightly woven for excellent mechanical strength

· Designed for extreme heat resistance

· Cost-effective and customizable

Applications

· Welding Protection: Blankets, curtains, and protective gear

· Thermal Insulation: Pipes, boilers, and industrial equipment

· Heat Shields: Furnaces, engines, exhaust systems

· Industrial Fabrics: Gaskets, protective covers, heat-resistant components

How can Fiberglass Textile be UV-Resistant?

Intrinsic UV Resistance of Glass Fibers

Glass fibers are inorganic silica-based materials that naturally have excellent resistance to UV radiation.

The fibers themselves do not degrade or weaken when exposed to UV light, maintaining structural integrity.

Role of the Resin Matrix

Fiberglass textiles are usually combined with organic resin matrices (like epoxy, polyester, or vinyl ester resins) to form composites.

These resins are generally sensitive to UV exposure and can degrade over time, leading to surface chalking, cracking, and loss of mechanical properties.

Addition of UV Stabilizers

UV absorbers and light stabilizers (e.g., HALS — Hindered Amine Light Stabilizers) are added to the resin or surface coatings.

These additives absorb or neutralize UV radiation, protecting the resin and extending the composite’s lifespan.

Surface Coatings and Protective Layers

Applying UV-resistant coatings, paints, or films on the fiberglass textile surface helps block or reflect UV rays.

These coatings also enhance weather resistance and waterproofing.

Improved Resin Formulations

Using specially formulated UV-resistant resins, such as certain epoxy or vinyl ester systems, increases the overall UV durability of the fiberglass composite.