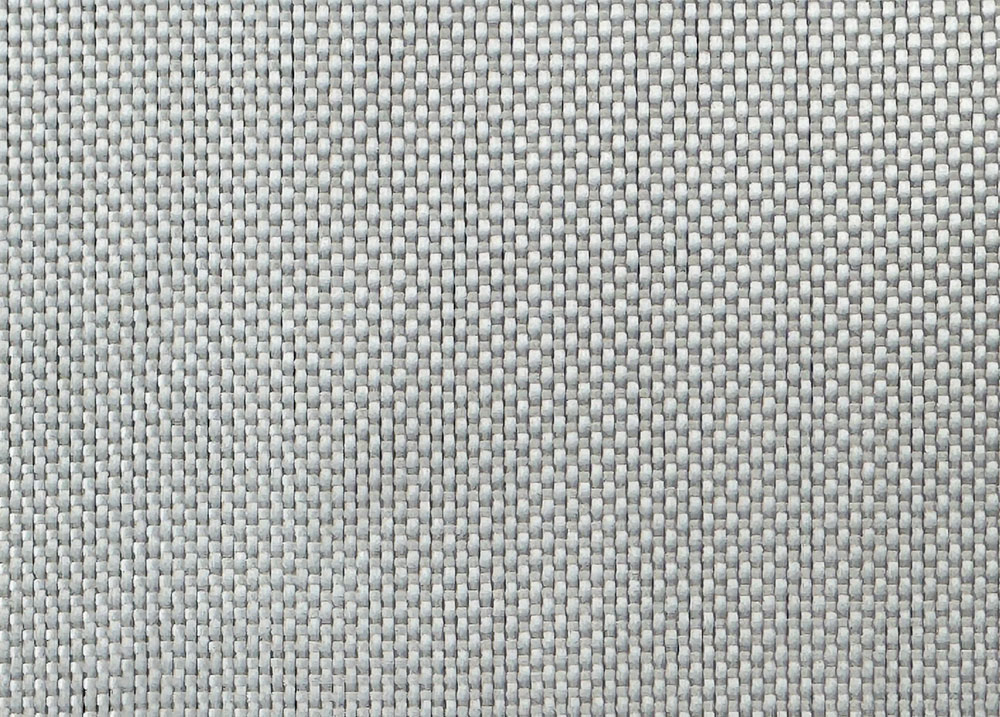

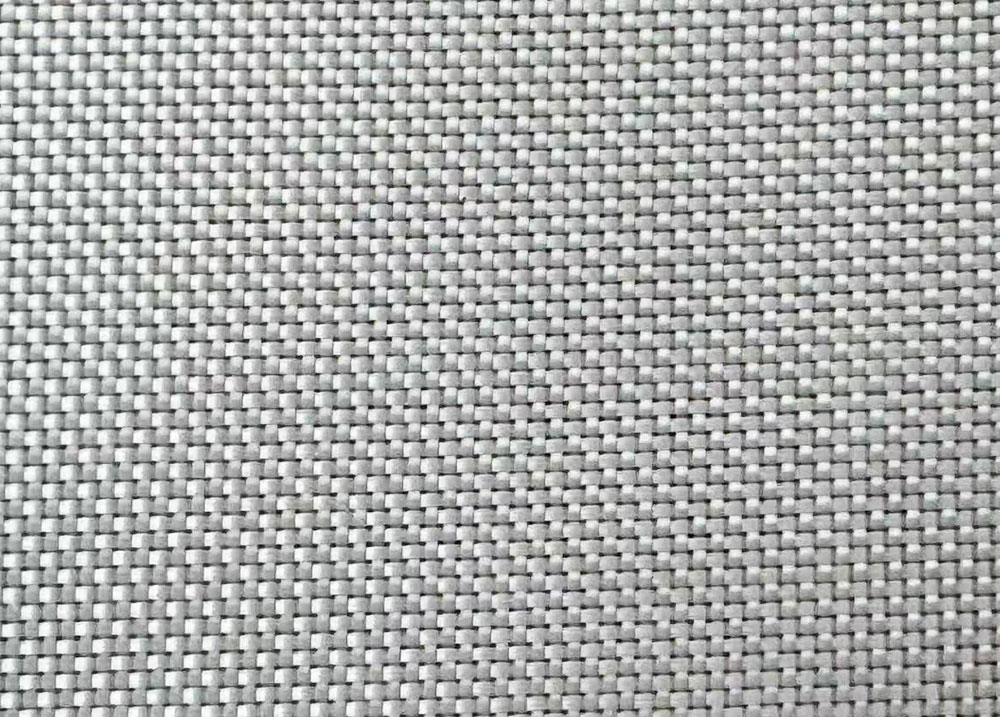

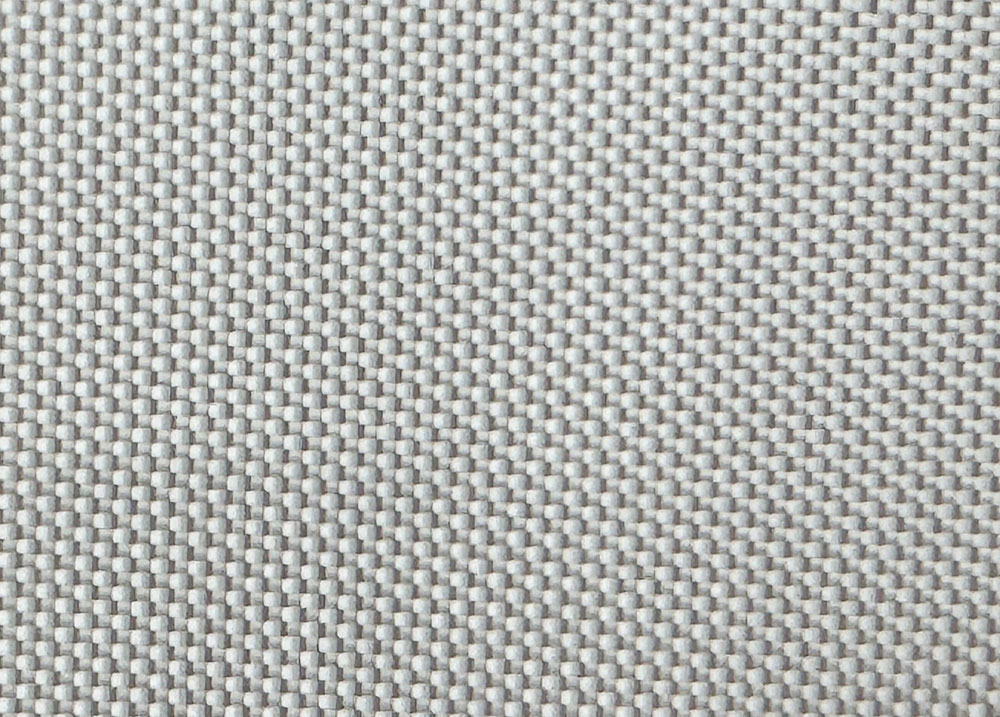

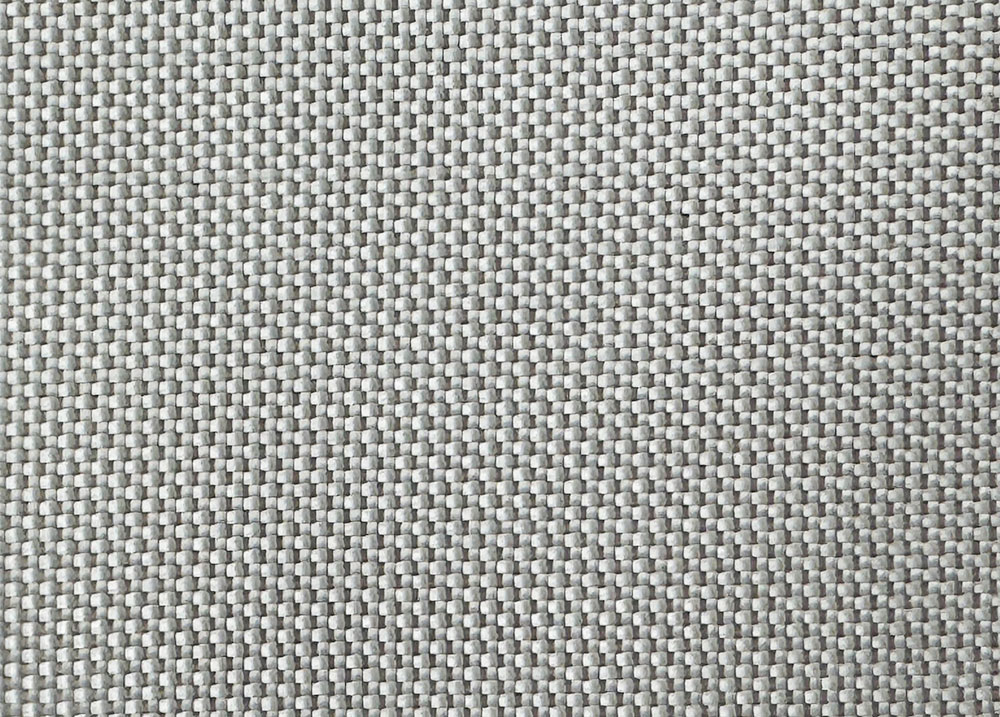

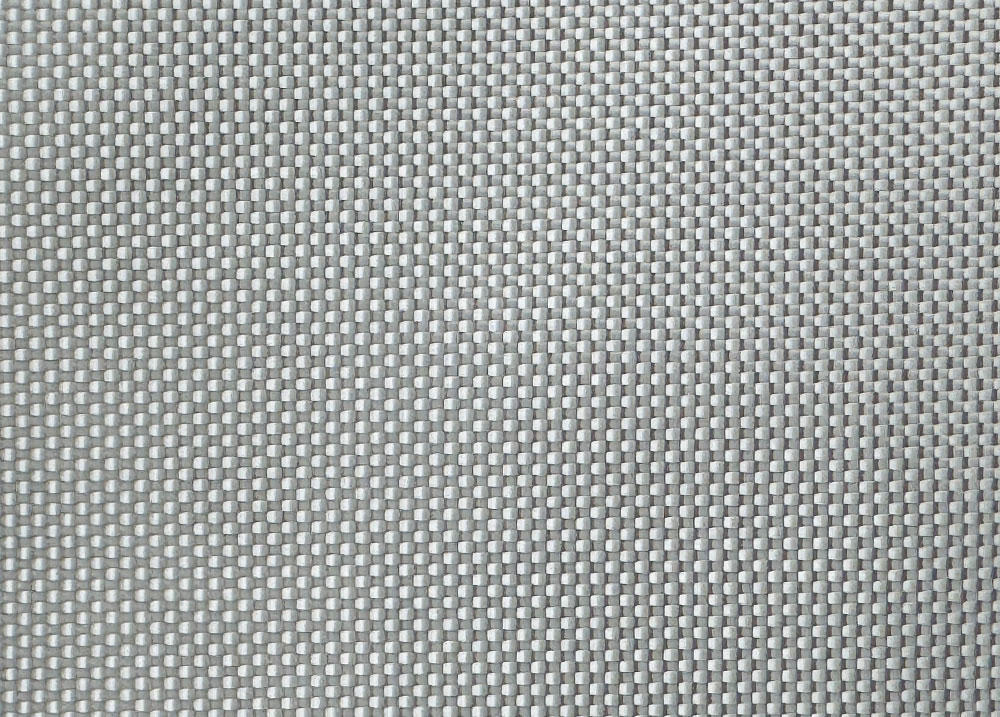

Fiberglass Cloth Plain Weave

· Compatible Resins: Polyester, Epoxy, Vinyl Ester

Key Features

· Good dimensional stability and moderate porosity

· Uniform strength in both directions

· Easy to handle and layer

· Medium-lightweight for strength and surface quality

Applications

· Lightweight Composites: Drones, boat panels, automotive interiors

· Structural Repair: Reinforcing damaged fiberglass parts

· Mold Making: Precision molds with smooth surface finish

Why Choose Plain Weave for Fiberglass Cloth?

When it comes to fiberglass cloth, the weave pattern isn’t just about looks—it’s a game-changer for performance. Among the various weave types, plain weave stands out as a favorite in industries demanding strength, durability, and reliability.

So, what makes plain weave special? Picture it as the “classic” pattern where each warp yarn crosses over and under each weft yarn evenly. This simple crisscross creates a tight, balanced fabric that resists distortion and holds its shape remarkably well.

From a mechanical standpoint, plain weave fiberglass offers excellent dimensional stability. This means when you’re molding or layering your composites, the fabric stays put, making the manufacturing process smoother and more predictable. It’s less prone to sagging or shifting compared to other weave types, which can save you headaches down the line.

But it’s not just about stability. The plain weave’s interlaced structure provides solid tensile strength, helping the finished product withstand stresses without cracking or breaking. This is why it’s so widely used in everything from aerospace components to automotive parts.

Of course, every choice comes with trade-offs. While plain weave is great for uniform strength and stability, it might not offer the same flexibility or drape as twill or satin weaves. But if your priority is durability and a reliable base for resin impregnation, plain weave fiberglass cloth is a smart, trusted pick.

In essence, the plain weave’s straightforward yet robust design makes it a dependable partner in building composites that last. It’s no wonder procurement specialists often turn to it when quality and consistency are non-negotiable.