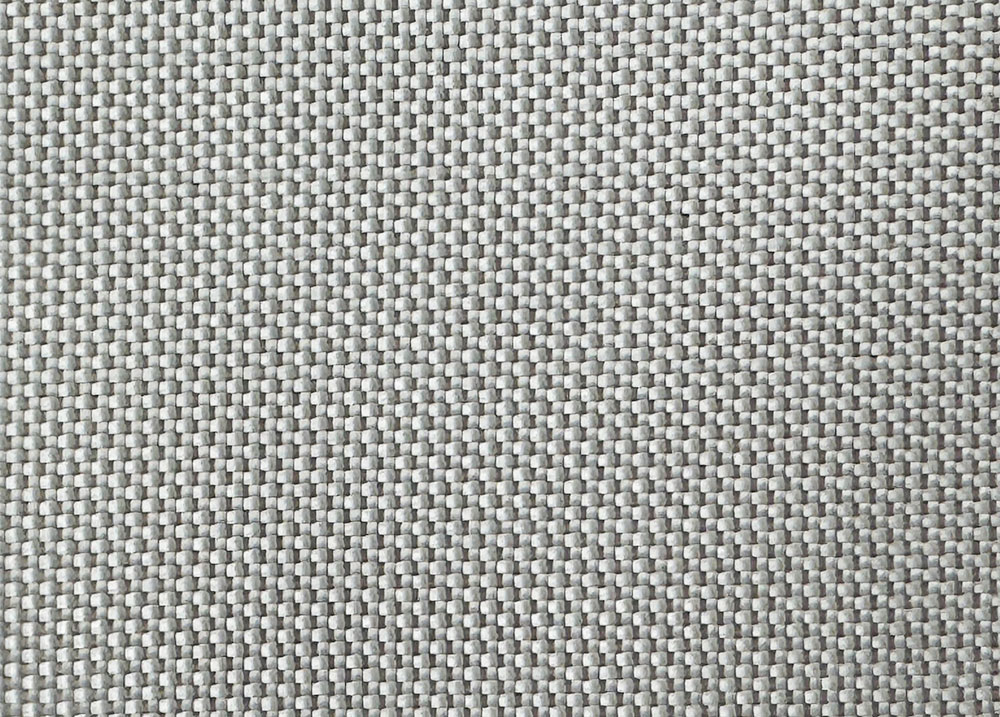

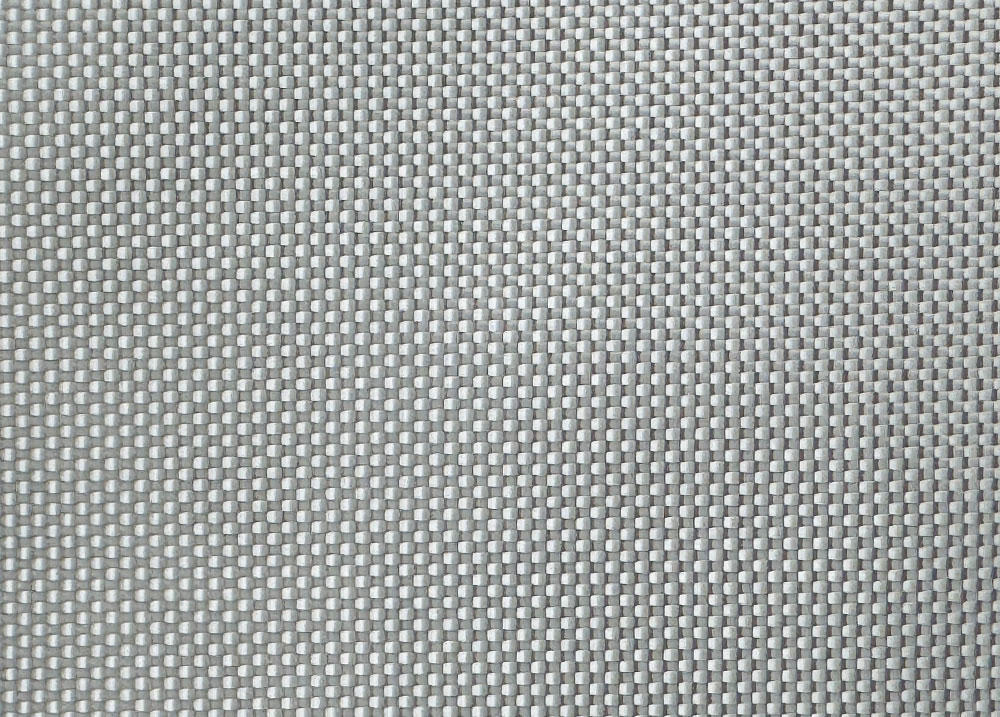

Glass Fiber Reinforced Plastic (GRP)

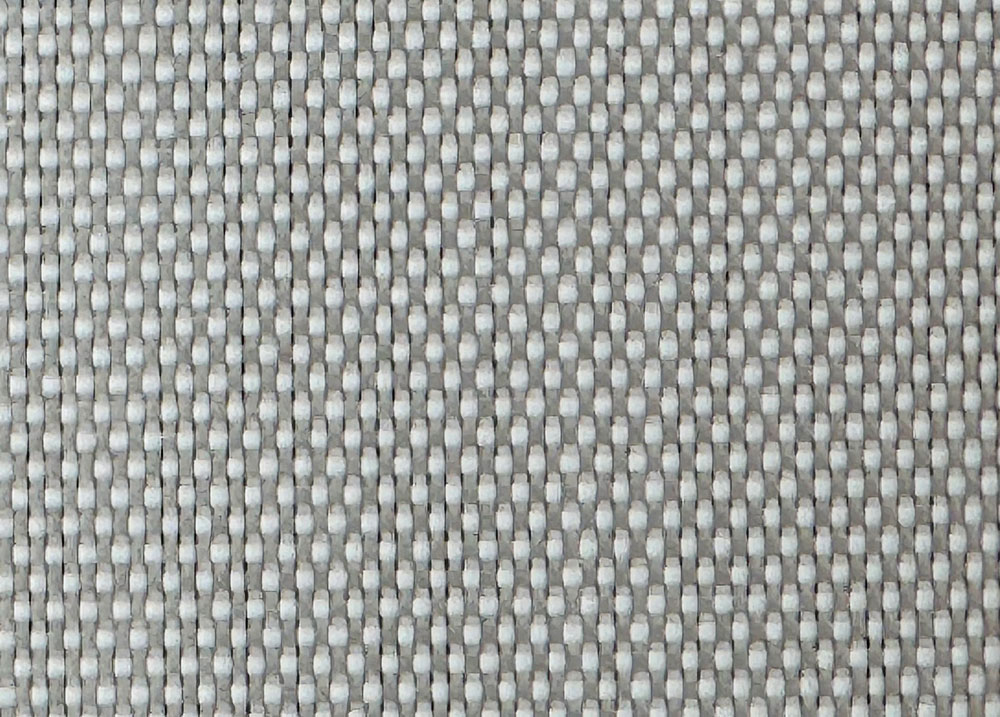

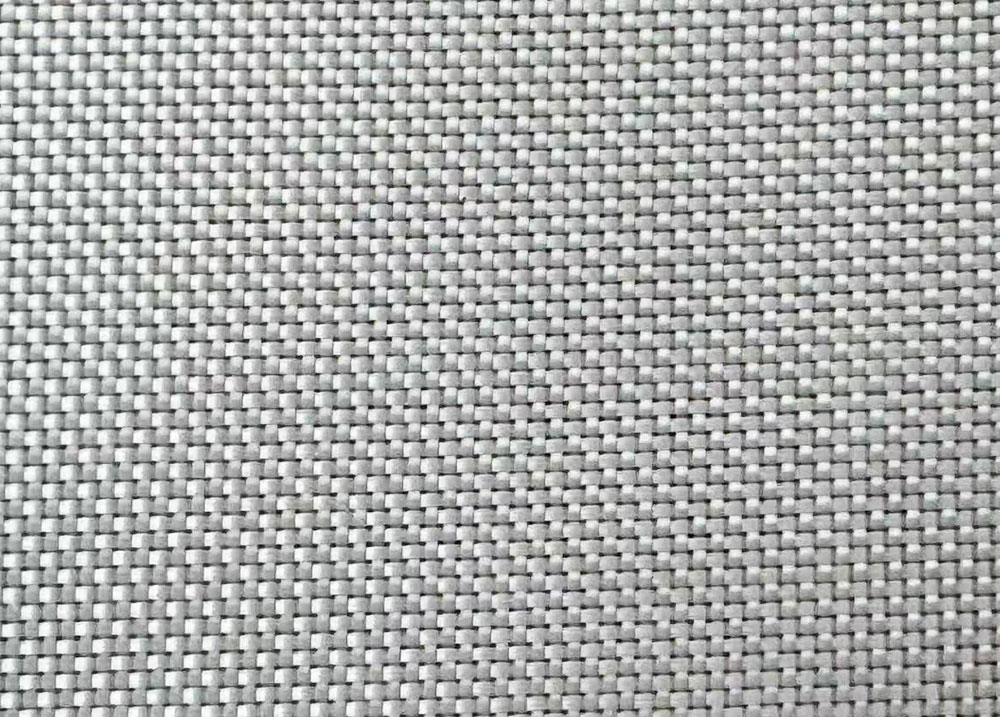

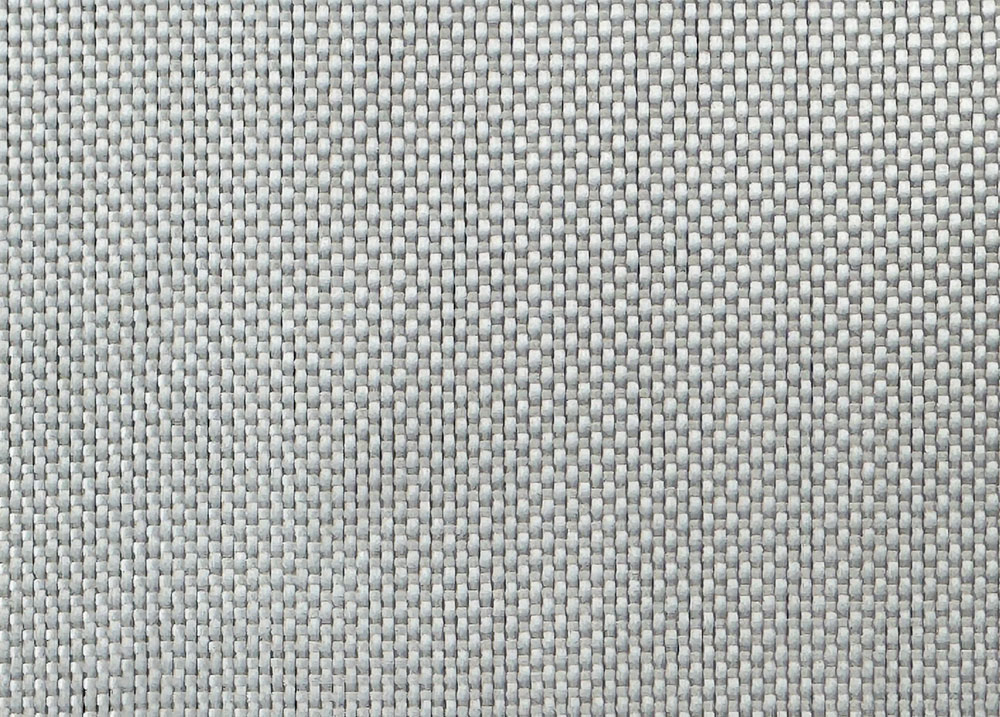

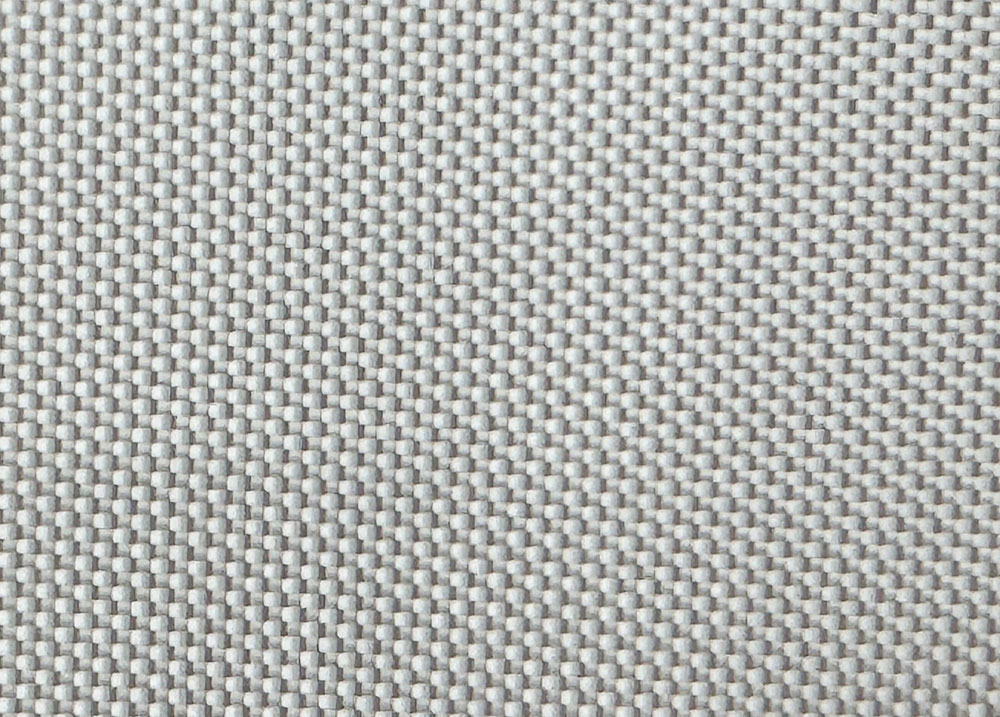

· Composition: Polymer resin matrix + glass fiber reinforcement

· Compatible Resins: Epoxy, Vinyl Ester, Polyester

· Fiber Types: E-glass, E-CR-glass

Key Features

· Excellent tensile and compressive strength

· High resistance to corrosion, chemicals, and harsh environments

· Durable and rigid, with low deformation under stress

· Balanced mechanical performance through fiber–resin synergy

Applications

· Industrial Components: Tanks, ducts, gratings, panels

· Infrastructure: Cable trays, structural supports, platforms

· Marine & Automotive: Housings, reinforcements, corrosion-resistant parts

Life Span of Glass Fiber Reinforced Plastic

The life span of Glass Fiber Reinforced Plastic (GFRP) can vary widely depending on several factors such as the resin type, manufacturing quality, environmental conditions, and the application it is used for.

Typical Life Span Range

- In normal indoor conditions: GFRP can last 30 to 50 years or even longer without significant degradation.

- In outdoor environments: The life span is typically 20 to 30 years, depending on exposure to UV radiation, moisture, temperature fluctuations, and chemical exposure.

Factors Affecting GFRP Life Span

Polyester resin-based GFRP generally has a shorter life span than epoxy or vinyl ester resin-based GFRP, which offer better durability.

UV rays can degrade the resin matrix over time, causing surface chalking and loss of mechanical properties.

- Moisture and chemical exposure

Prolonged exposure to water, acids, alkalis, or solvents can reduce the material's structural integrity.

Repeated loading, impacts, and fatigue affect the longevity of GFRP parts.

Proper curing and fiber distribution enhance life span; defects can cause early failure.

Maintenance and Protection

Applying UV protective coatings, regular inspections, and avoiding harsh chemicals can extend the life span.