High Quality Fiberglass Cloth

· Compatible Resins: Polyester, Epoxy, Vinyl Ester

Key Features

· Excellent balance of strength, durability, and workability

· Produces smooth, professional surface finish

· Easy to handle and suitable for hand lay-up or resin infusion

· Reliable performance for structural and cosmetic applications

Benefits

· Cost-Effective: Strong performance at an accessible price point

· Versatile: Suitable for both industrial and creative use

· Aesthetic Finish: Ideal for parts with visible surfaces

Applications

· General Composites: Panels, covers, housings

· Creative Projects: Sculptural works, furniture, surfboards

· Repairs & Reinforcement: Structural strengthening and cosmetic fixes

What Defines High Quality Fiberglass Cloth?

When evaluating whether a fiberglass cloth is high quality, several key factors should be considered:

Raw Material Quality

Made from premium glass fiber yarns with consistent and fine fiber diameters to ensure strength and stability.

High-purity fibers free from impurities that could weaken the material.

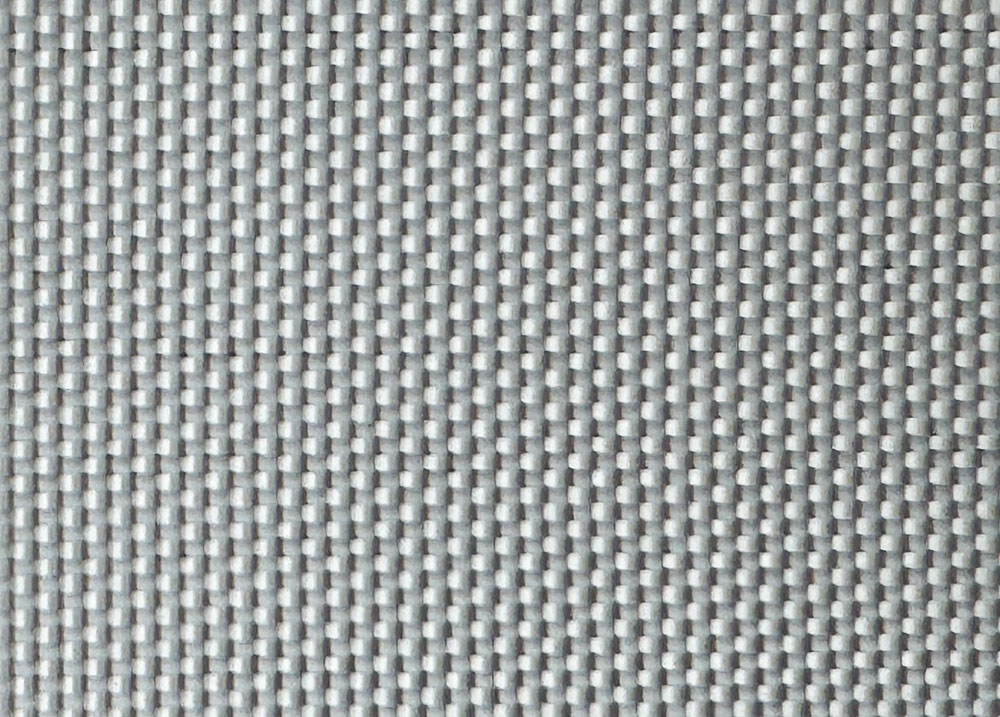

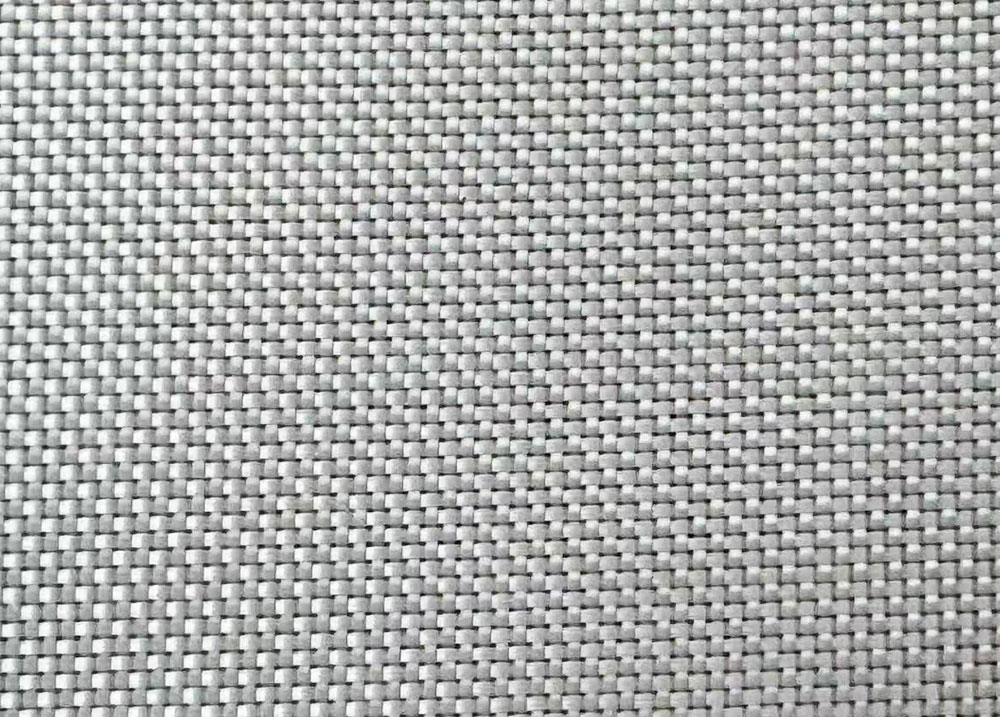

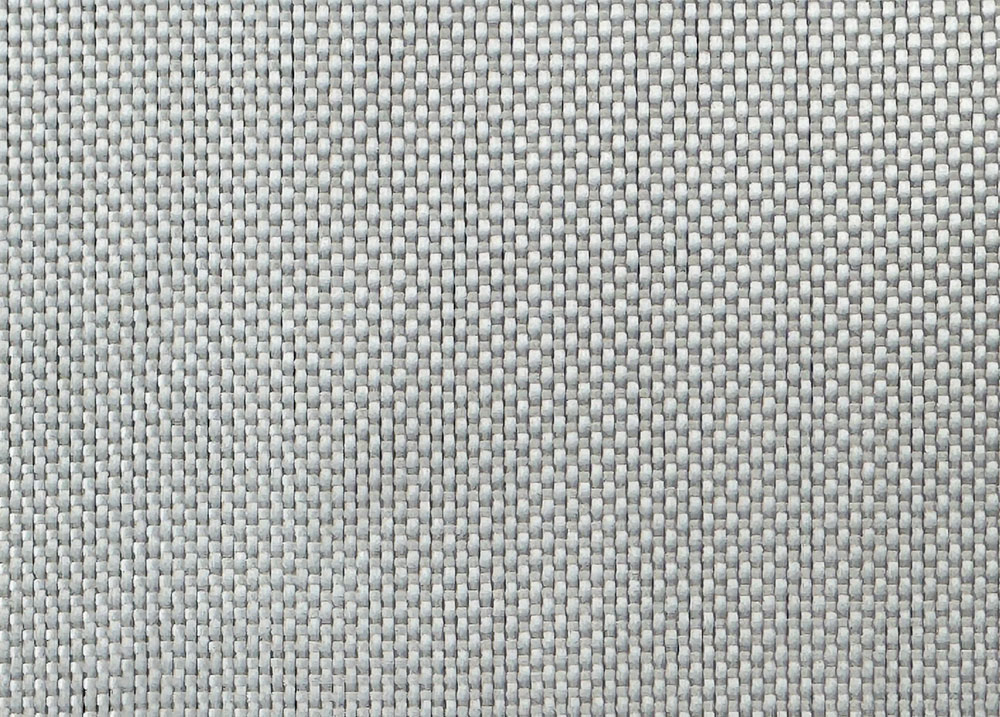

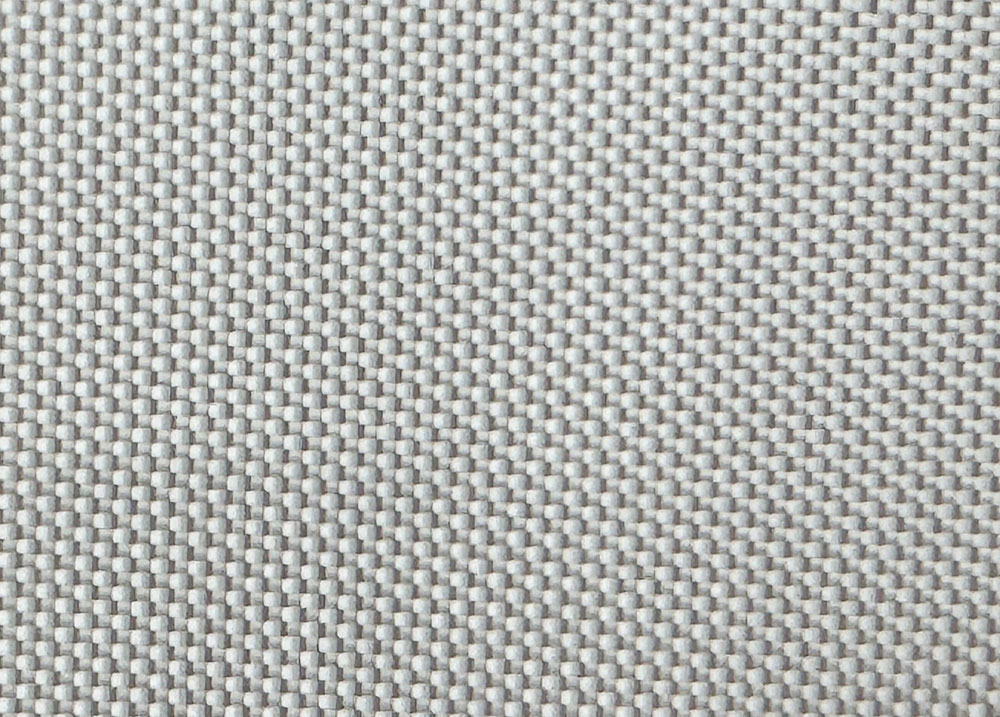

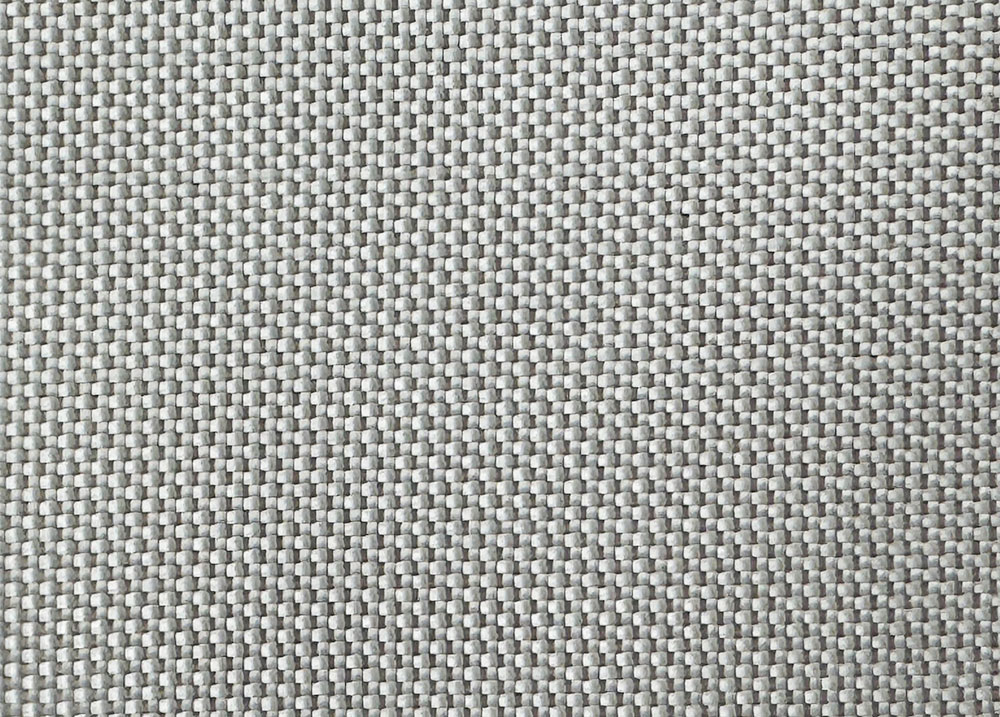

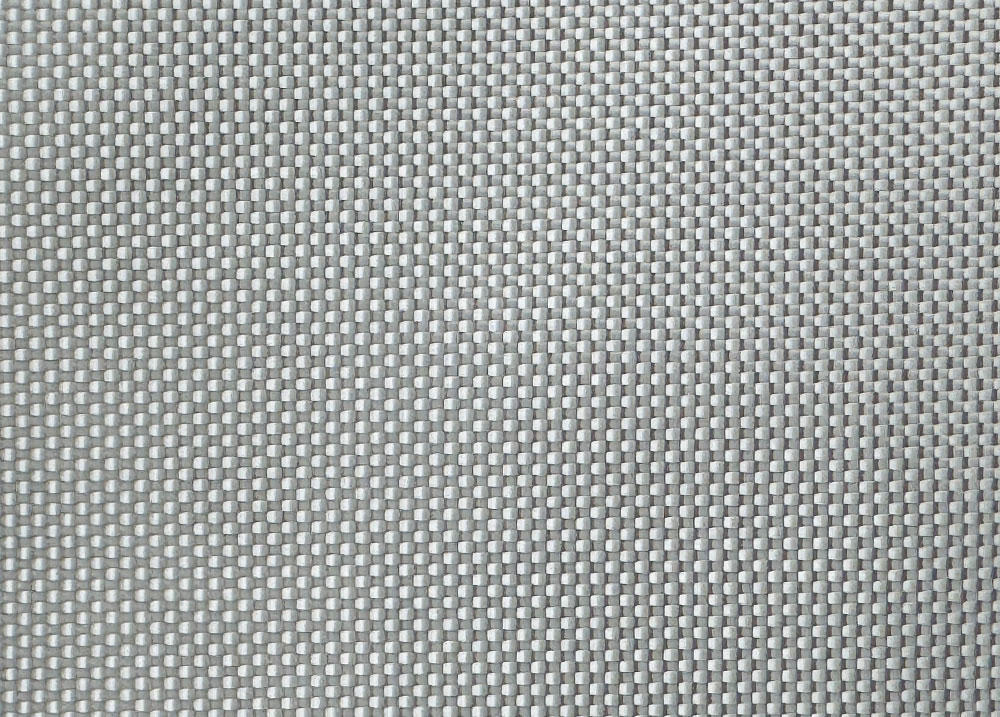

Weaving Process

Tight and uniform weave with well-aligned yarns, avoiding loose areas, broken yarns, or visible defects.

Appropriate weave density to balance strength and flexibility based on application needs.

Smooth, even surface without burrs or rough spots.

Fabric Weight (gsm)

Stable and specification-compliant weight; too light may lack strength, too heavy can impact processing and cost.

Weight should be chosen to suit the end use.

Mechanical Properties

High tensile strength and tear resistance to withstand applied stresses without breaking.

Good elongation at break, indicating suitable flexibility.

Dimensional Stability

Heat-set or otherwise processed to prevent shrinkage or deformation during curing or use.

Consistent shape and size to facilitate resin impregnation and composite forming.

Chemical and Environmental Resistance

Excellent resistance to acids, alkalis, and corrosive environments.

Good heat resistance and UV stability to ensure long service life outdoors.

Resin Compatibility

Easily wetted by various resin systems (epoxy, polyester, vinyl ester), ensuring strong bonding and optimal composite properties.

Brand and Certifications

Sourced from reputable manufacturers with quality certifications (e.g., ISO 9001, ASTM standards) to ensure consistent quality.