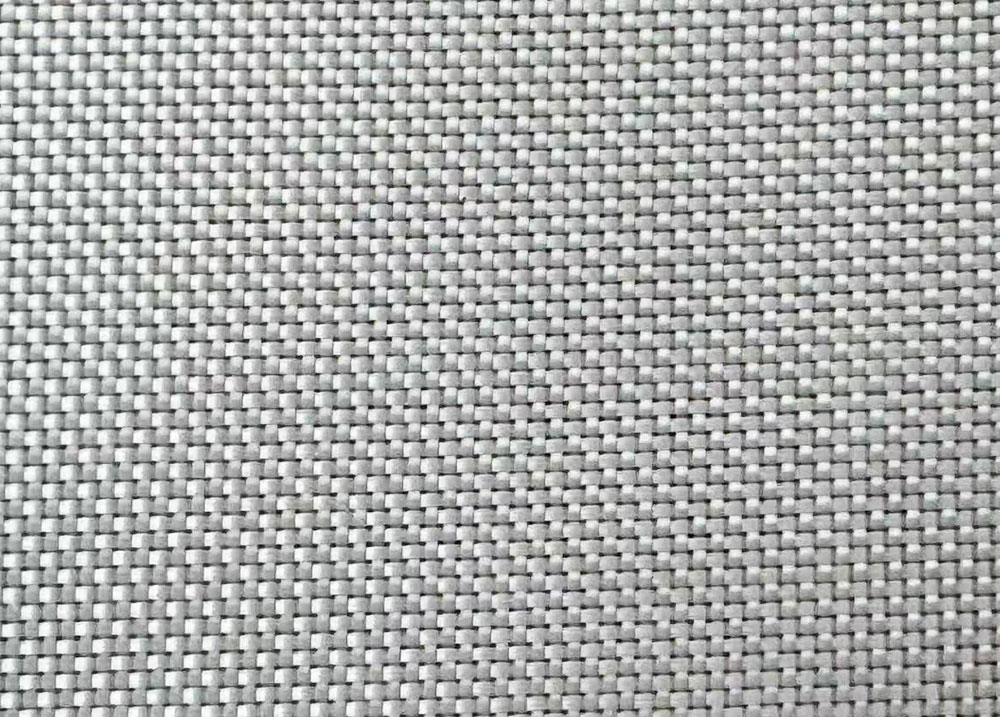

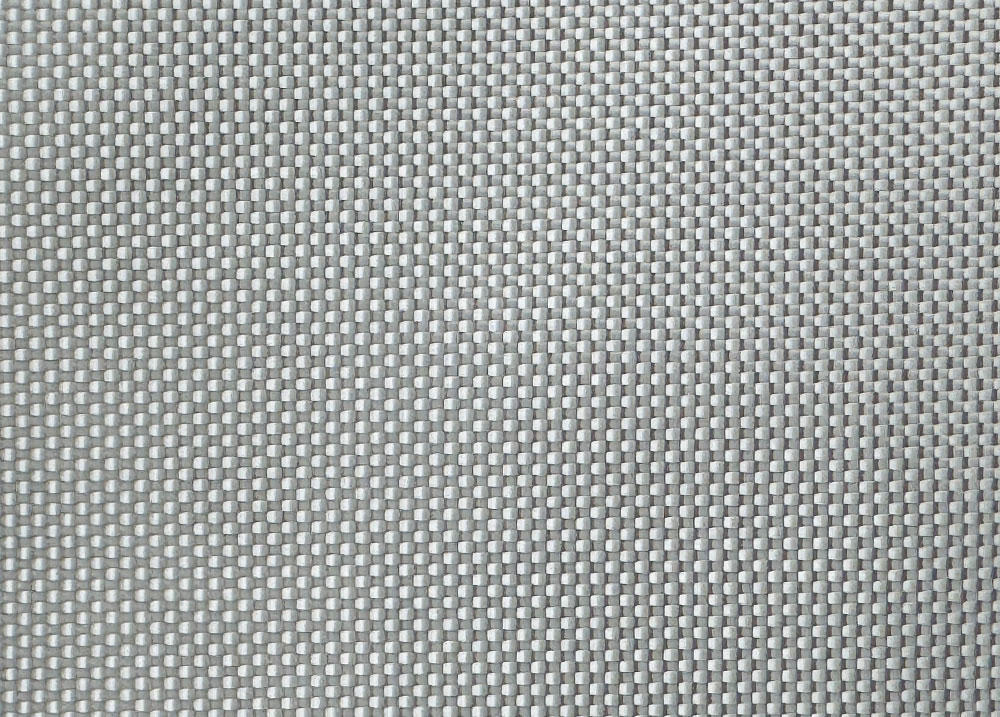

Woven Glass Cloth Reinforcement

· Compatible Resins: Polyester, Epoxy, Vinyl Ester

Key Features

· Strong, lightweight, and durable

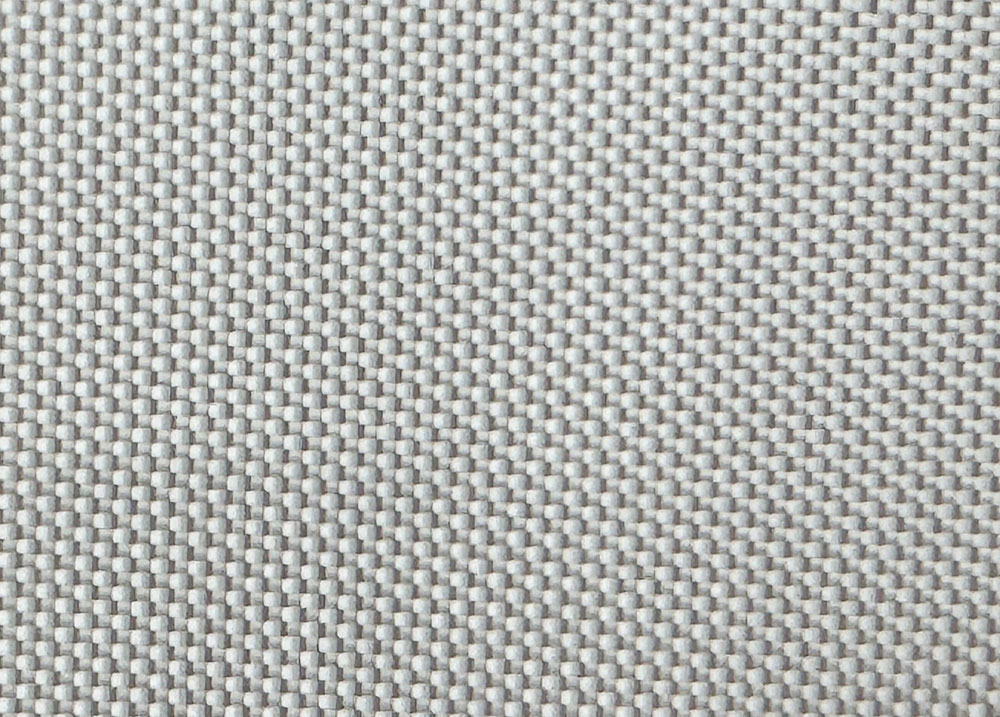

· Continuous fiber cloth without binder

· Superior mechanical properties vs. chopped strand mats (CSM)

Applications

· RC wings and airframes

· Vehicle panels

· Surfboards and dinghies

· Fiberglass molds and composites

Strengthening Composites with Woven Glass Cloth Reinforcement

Woven glass cloth reinforcement is a type of fabric made from woven fiberglass yarns, widely used to enhance the mechanical strength and durability of composite materials. Its excellent tensile strength, thermal stability, and chemical resistance make it a preferred reinforcement in industries ranging from aerospace to electronics.

What is Woven Glass Cloth Reinforcement?

Woven glass cloth consists of continuous glass fibers woven into a fabric using various weave patterns like plain, twill, or satin. These fabrics serve as reinforcement layers embedded within resin matrices (such as epoxy, polyester, or vinyl ester), forming fiberglass-reinforced composites with improved structural performance.

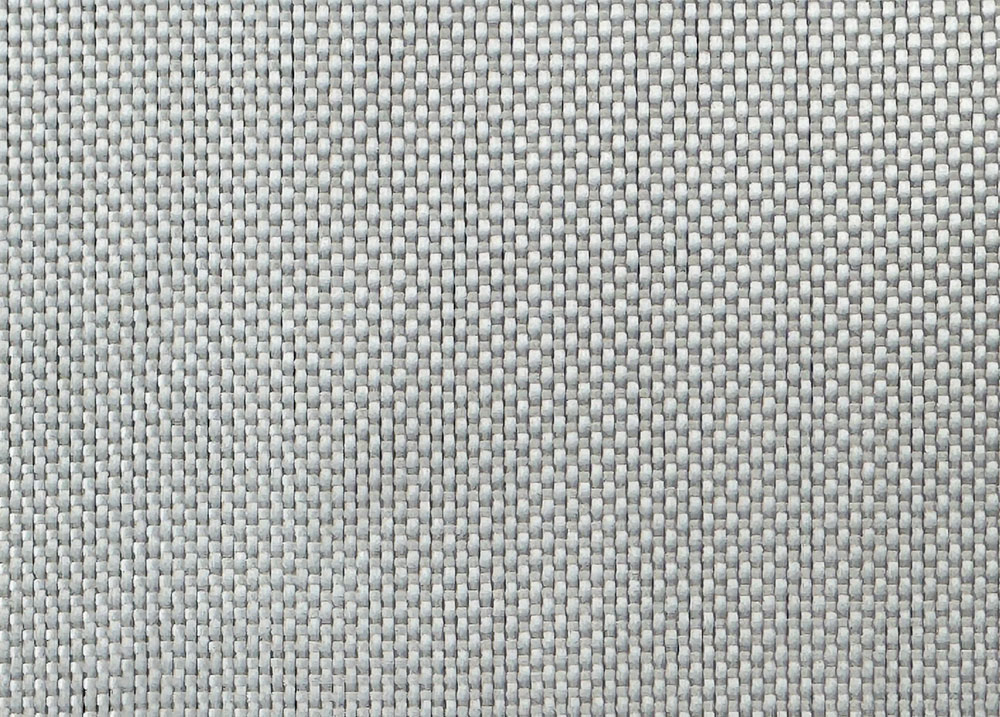

Key Properties of Woven Glass Cloth

- High Tensile Strength: Glass fibers provide superior load-bearing capacity, increasing composite strength.

- Thermal Stability: Resistant to high temperatures, woven glass cloth maintains integrity in demanding environments.

- Chemical Resistance: It withstands exposure to solvents, acids, and alkalis, ensuring longevity in harsh conditions.

- Dimensional Stability: The weave pattern controls fabric drape and thickness, allowing precise composite shaping.

- Electrical Insulation: Glass fibers are non-conductive, making the cloth ideal for electrical and electronic applications.

Common Applications

- Composite Manufacturing: Used extensively in boat hulls, automotive parts, wind turbine blades, and aerospace components.

- Printed Circuit Boards (PCBs): Acts as a dielectric substrate due to excellent insulation and thermal properties.

- Thermal and Acoustic Insulation: Employed in protective clothing and insulation blankets.

- Construction and Infrastructure: Reinforces concrete, roofing materials, and protective coatings.

Advantages of Using Woven Glass Cloth Reinforcement

- Uniform strength distribution due to balanced weave.

- Customizable fabric weight and weave pattern for specific mechanical requirements.

- Ease of handling and cutting during composite layup processes.

- Compatibility with a wide range of resin systems.

Woven glass cloth reinforcement is a versatile and critical material for enhancing composite structures’ mechanical and chemical performance. Its unique combination of strength, thermal resistance, and electrical insulation makes it indispensable across multiple high-tech industries.