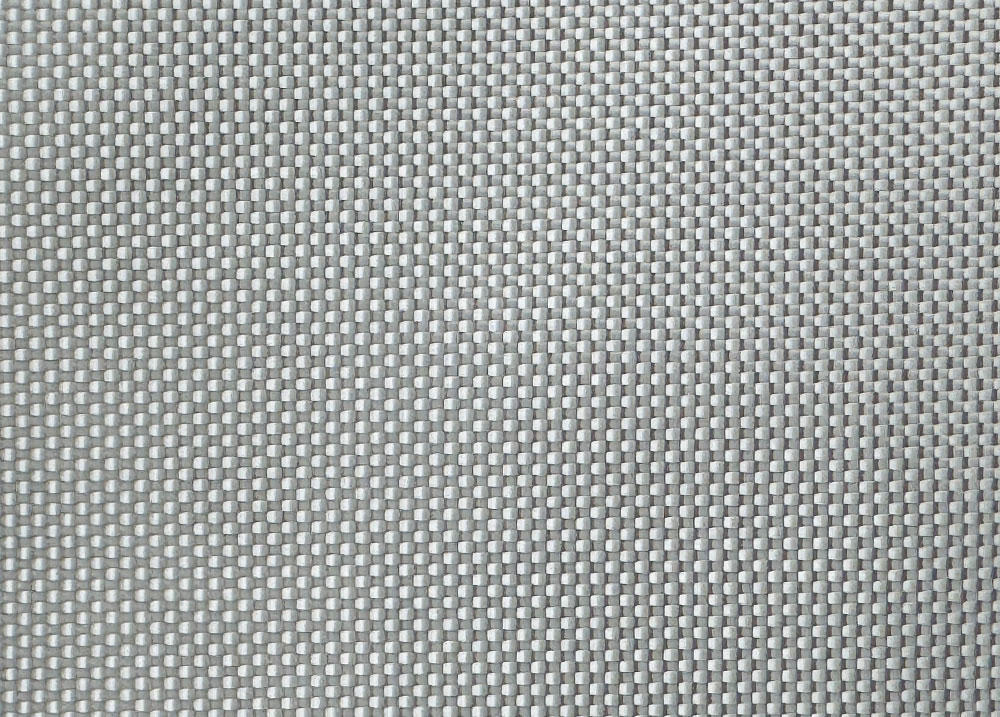

Fiberglass Woven Roving Plain Weave

· Compatible Resins: Polyester, Vinyl Ester, Epoxy

Key Features

· Heavy-duty fabric for fast thickness build-up

· Strong continuous filament yarns for excellent mechanical strength

· Easy resin wet-out and good durability

· Cost-effective for large, flat laminates

Applications

· Marine Industry: Boat hulls, decks, and structural components

· Industrial Composites: Tanks, panels, automotive parts

· Repairs & Reinforcement: Strengthening damaged or load-bearing areas

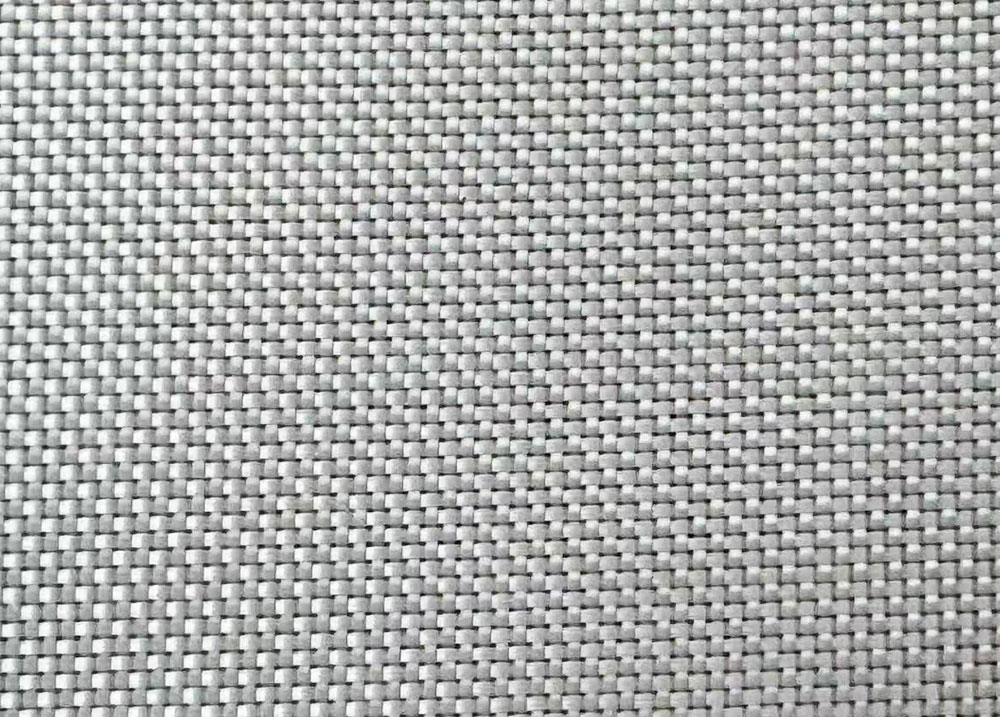

Right Weight of Plain Weave Woven Roving Fiberglass Cloth for Different Applications

Not all fiberglass cloths are created equal, especially when it comes to their weight. The gram weight of plain weave woven roving fiberglass cloth plays a crucial role in determining where and how it performs best.

Lightweight fabrics, typically under 300 g/m², are prized for their flexibility and ease of handling. They’re perfect for intricate molds, delicate parts, or layered composites where every gram counts. These lighter weaves drape easily, making them favorites in automotive interiors, marine applications, and lightweight structural panels.

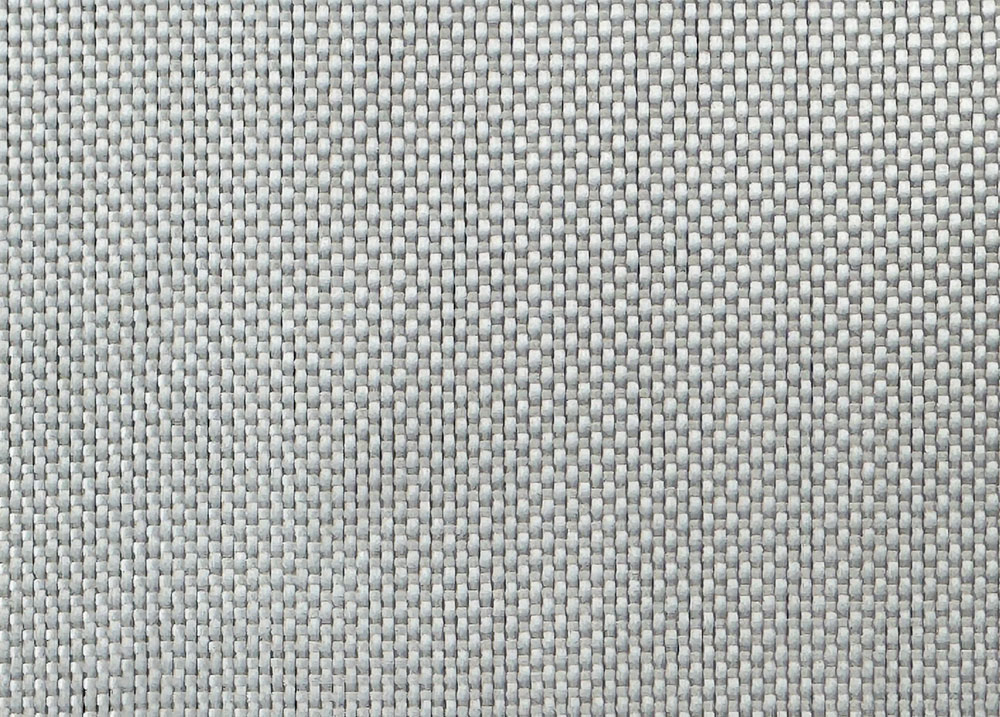

On the other end, heavier fabrics—those above 600 g/m²—bring strength and rigidity to the table. They’re the go-to choice when durability and load-bearing capacity are non-negotiable. Think industrial equipment, wind turbine blades, and heavy-duty construction reinforcements where robustness is king.

Mid-weight fabrics strike a balance, offering a blend of workability and strength, ideal for general-purpose use in aerospace components, sporting goods, and electrical insulation.

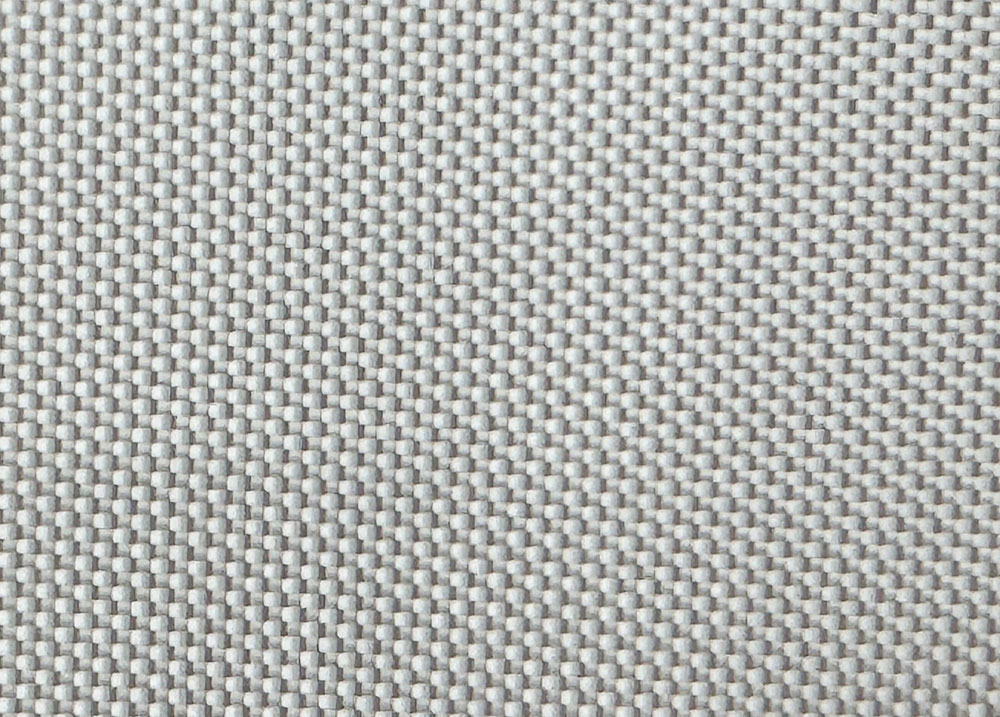

Choosing the right weight is less about a one-size-fits-all and more about matching the fabric’s character to the demands of your project. Understanding these nuances ensures your composite material doesn’t just perform—but excels.