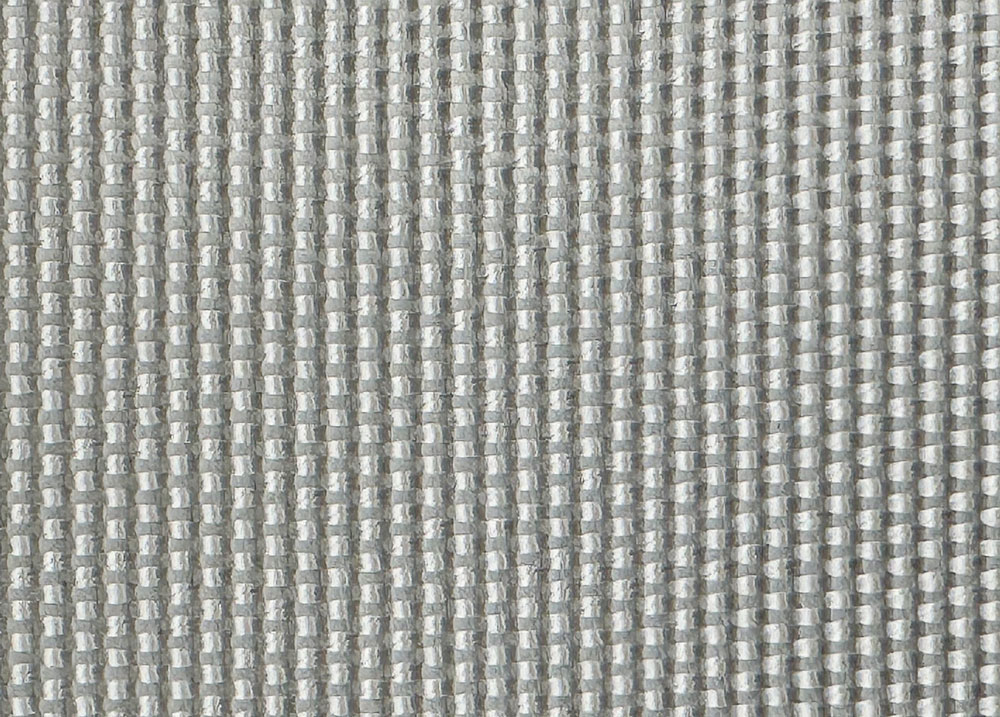

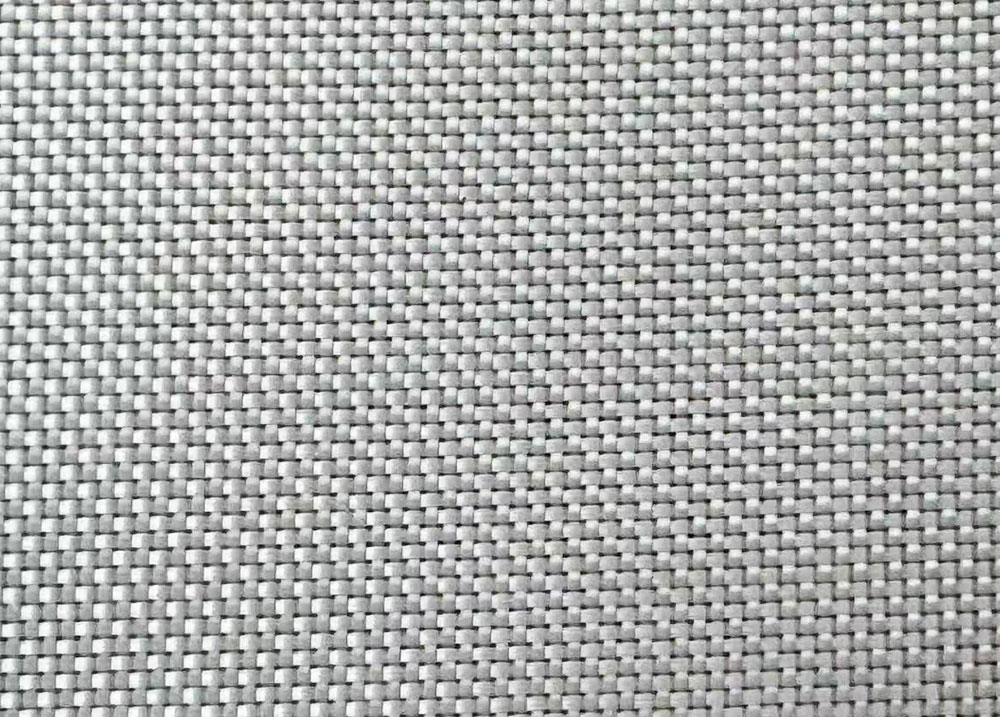

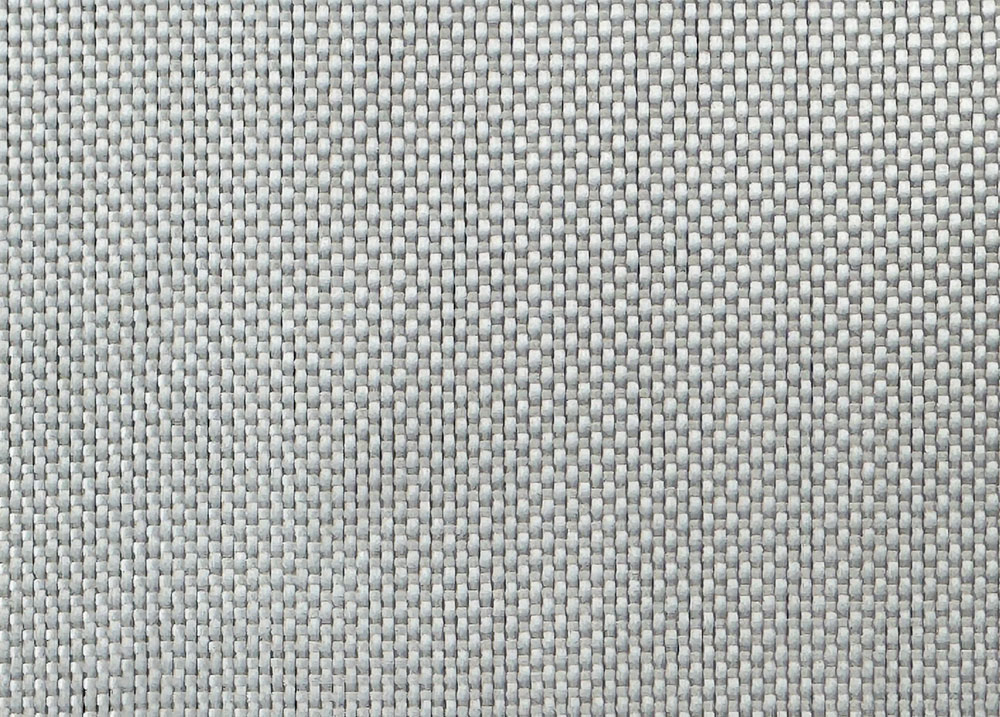

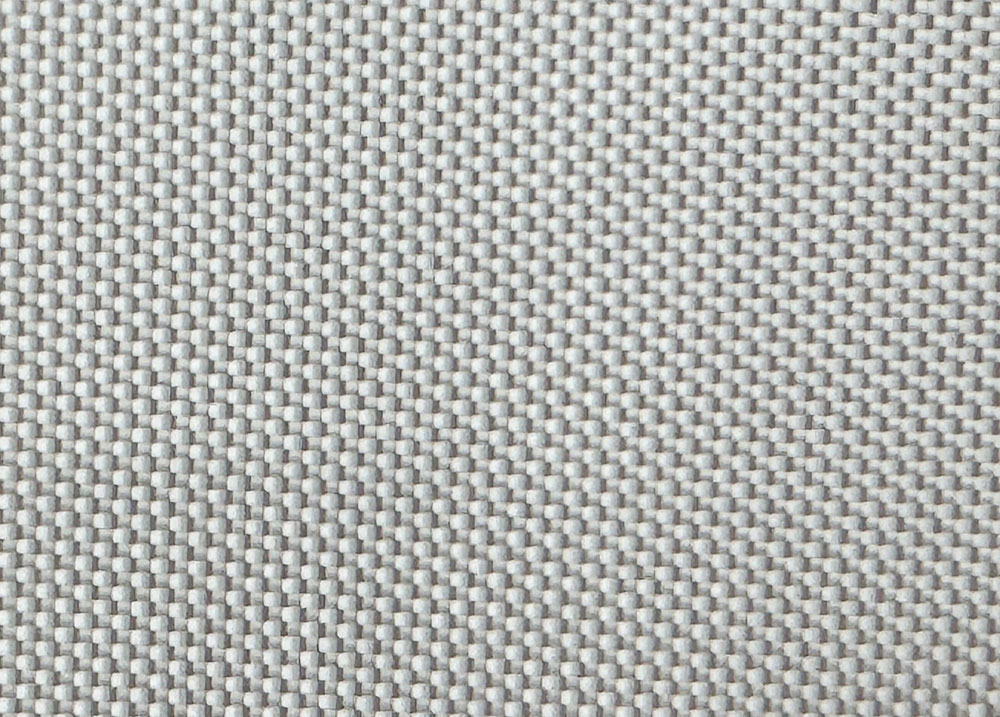

Heavy Duty Fiberglass Cloth for Repairing

· Compatible Resins: Polyester, Epoxy, Vinyl Ester

Key Features

· High mechanical strength for demanding repairs

· Excellent thermal resistance and durability

· Water and corrosion resistant for marine use

· Fire-resistant properties suitable for industrial and construction environments

· Handles well during lamination; creases can be easily straightened

Applications

· Structural Repairs: Boats, decks, machinery, and damaged components

· Marine Industry: Reinforcements exposed to moisture and corrosion

· Electrical & Electronics: Insulation tapes, cable binding, coil wrapping

· Industrial Maintenance: Repairs for tanks, pipes, and equipment

· Construction: Panels, roofing, fire-resistant building materials

Why Fiberglass Cloth for Repairing Needs Heavy-duty?

Because repair applications typically demand higher strength, durability, and resilience than new construction or light-duty uses.

Here are the main reasons why:

1. High Stress and Load Bearing

Repairs usually involve damaged or weakened structures that must regain or even exceed their original strength. Heavy-duty fiberglass cloth provides greater tensile strength and impact resistance to withstand these stresses.

2. Durability in Harsh Environments

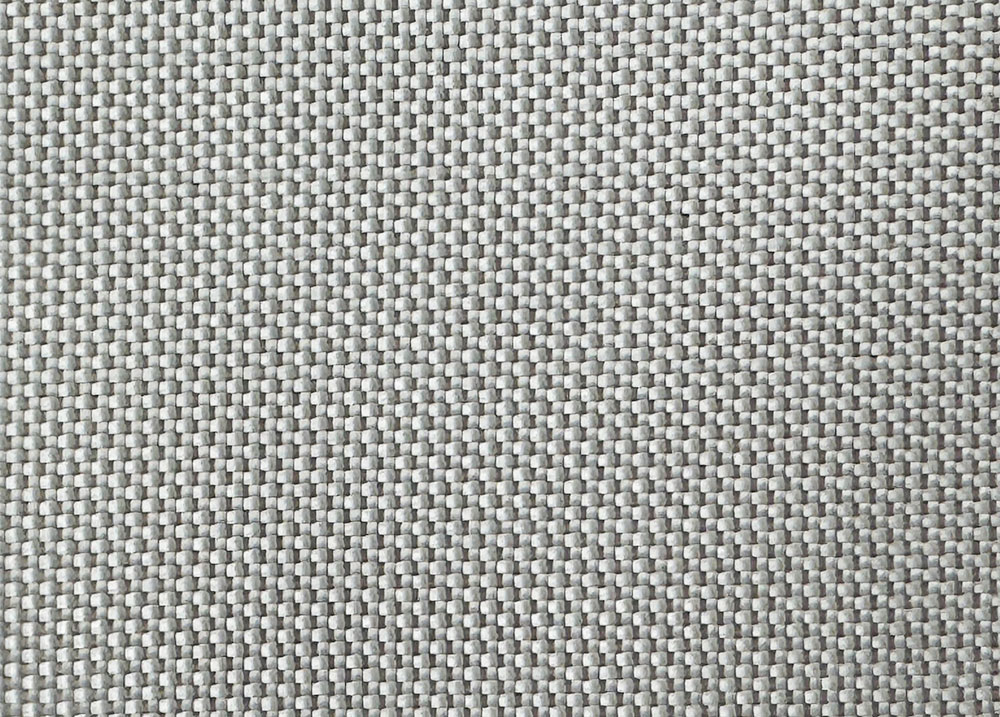

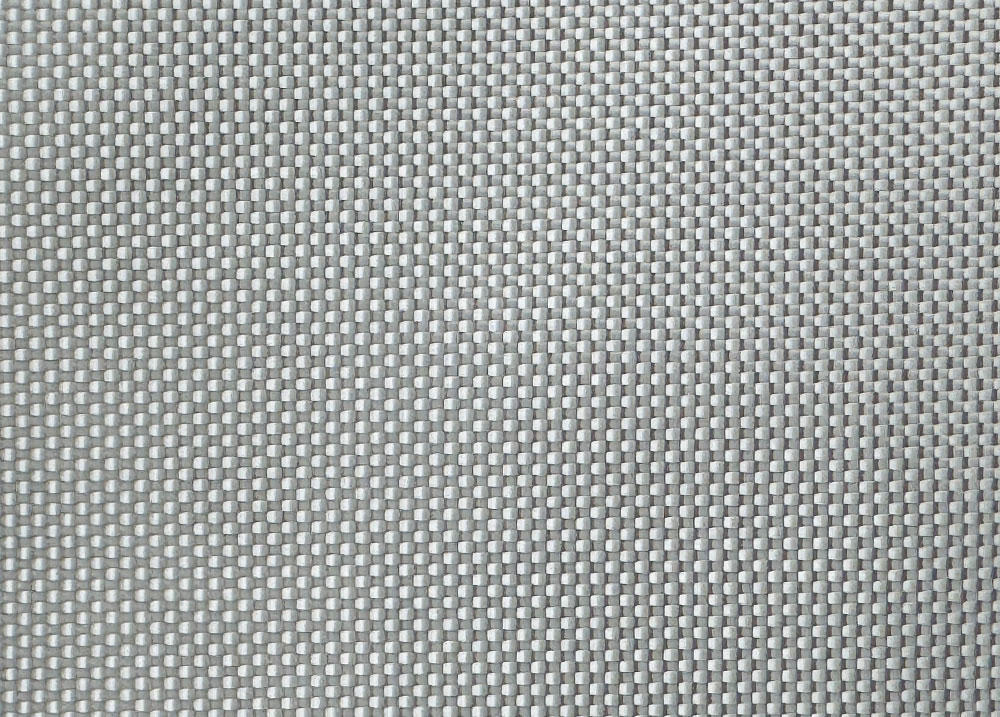

Repair materials often face tough conditions—exposure to moisture, chemicals, UV light, temperature fluctuations, and mechanical wear. Heavy-duty cloth has thicker fibers and tighter weaving, making it more resistant to these factors and extending repair longevity.

3. Improved Adhesion and Layering

Heavy-duty fiberglass cloth has a denser weave and higher weight, which helps it bond better with resin systems (epoxy, polyester, etc.) and creates a thicker, more robust composite layer during repair.

4. Crack and Damage Bridging

Thicker and stronger cloth can better bridge gaps, cracks, or holes in the substrate, preventing further propagation of damage and restoring structural integrity effectively.

5. Better Handling and Application

Heavy-duty cloth is often easier to handle during repair—less prone to tearing or distortion—helping ensure a smoother, more effective repair process.