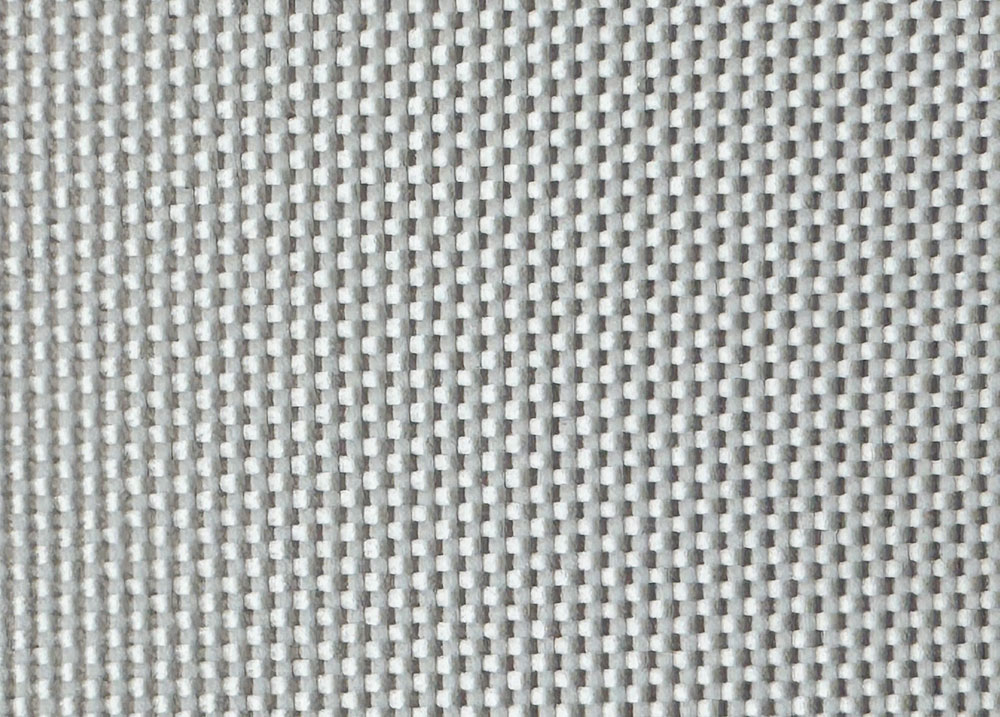

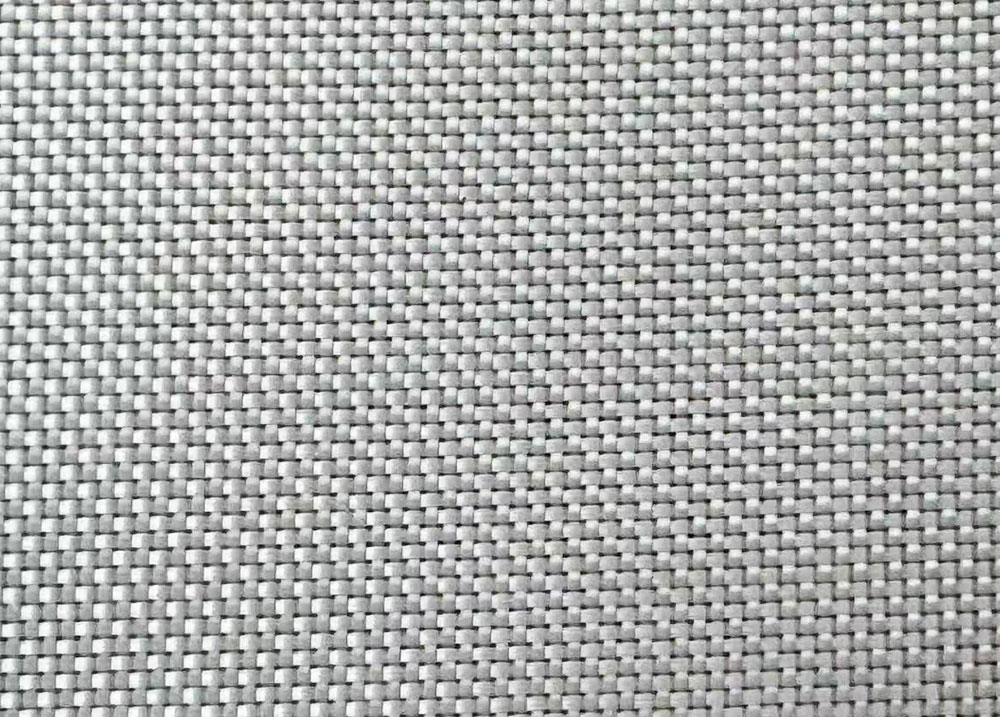

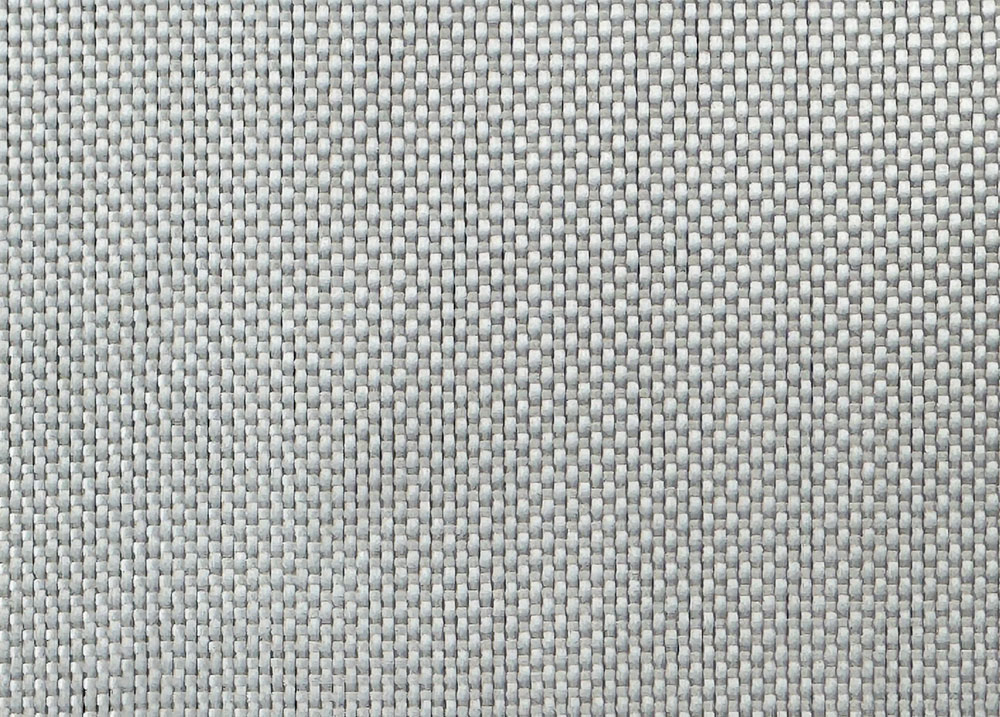

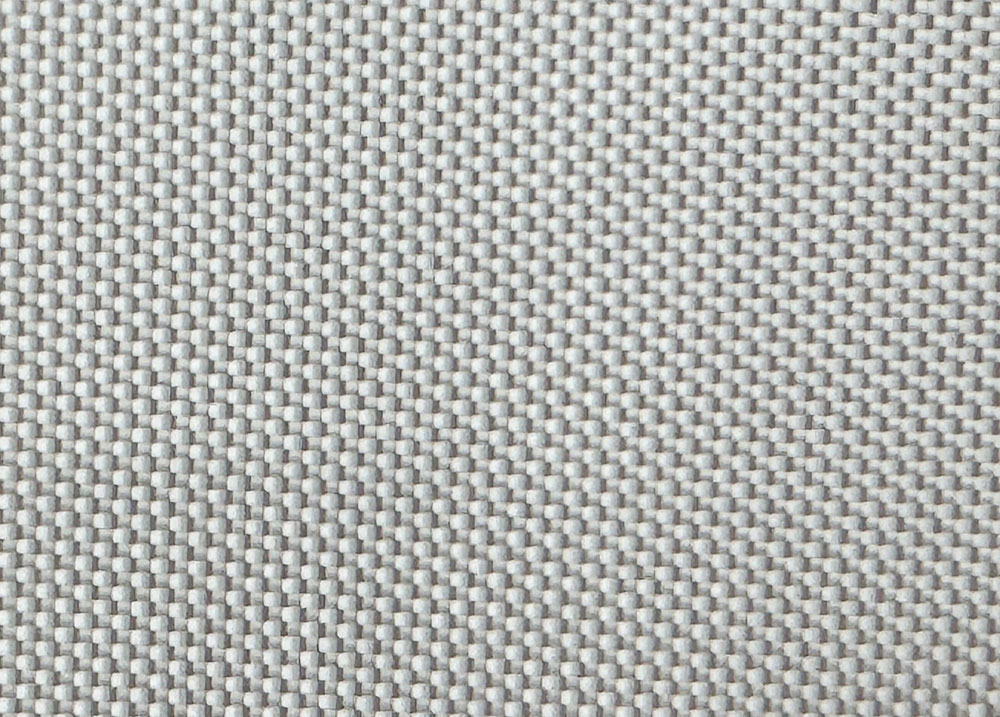

Woven Fiberglass Cloth

· Compatible Resins: Polyester, Epoxy, Vinyl Ester

Key Features

· High-strength fabric for demanding applications

· Excellent rigidity and structural reinforcement·

· Resin-compatible for smooth saturation and bonding

· Durable in marine and industrial environments

· Easy to cut, shape, and layer

Applications

· Marine: Boat hulls, decks, and structural reinforcements

· Industrial: Tanks, pipes, machinery housings

· Construction: Panels, roofing, structural layers

· Repair: Reinforcement of damaged composite parts

How can Woven Fiberglass Cloth be Heat-resistant?

Woven Fiberglass Cloth is heat-resistant primarily because of the inherent properties of glass fibers and the way the cloth is manufactured and treated. Here’s how it achieves heat resistance:

Inherent Thermal Stability of Glass Fibers:

Glass fibers are made from silica-based materials with a very high melting point (typically above 1000°C or 1832°F). This gives them excellent resistance to high temperatures without melting, burning, or degrading.

Low Thermal Conductivity:

Glass fibers have low thermal conductivity, which means they don’t easily transfer heat. This property helps protect structures or materials wrapped or reinforced with woven fiberglass cloth from heat damage.

Use of High-Temperature Resistant Resins:

When woven fiberglass cloth is used in composites, it is often combined with heat-resistant resin matrices such as epoxy, phenolic, or silicone resins. These resins help the overall material maintain structural integrity at elevated temperatures.

Thermal Treatment and Sizing:

The glass fibers and fabrics often undergo specific heat treatments and surface sizing that enhance their thermal stability and bonding with resins.

Resistance to Thermal Shock:

Woven fiberglass cloth can withstand rapid temperature changes without cracking or losing strength, which is critical in many industrial applications.