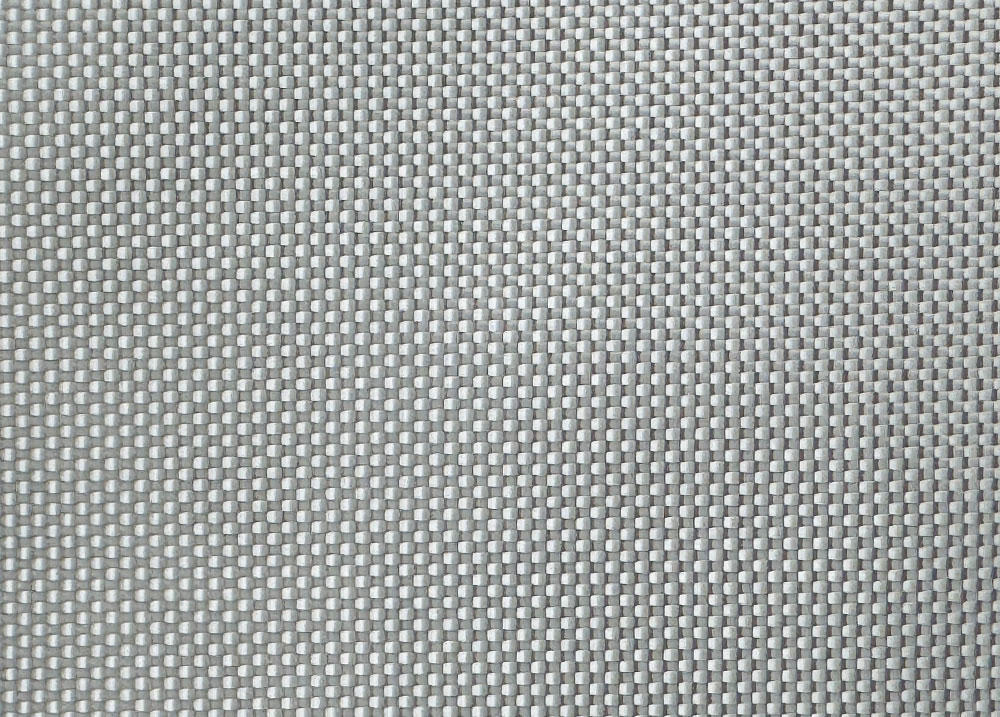

Glass Fabric Weaving

· Compatible Resins: Polyester, Epoxy, Vinyl Ester

Key Features

· Heavy-duty reinforcement with high strength and rigidity

· Uniform fiber distribution for consistent mechanical performance

· Durable, non-conductive, and heat-resistant

· Reliable performance in harsh and high-stress environments

Applications

· Industrial Composites: Tanks, pipes, structural parts

· Marine: Boat hulls, decks, and marine reinforcements

· Construction: Panels, roofing, and structural building materials

· Electrical Insulation: Non-conductive layers for heat and safety protection

· Repairs & Reinforcement: Strengthening or restoring damaged composite structures

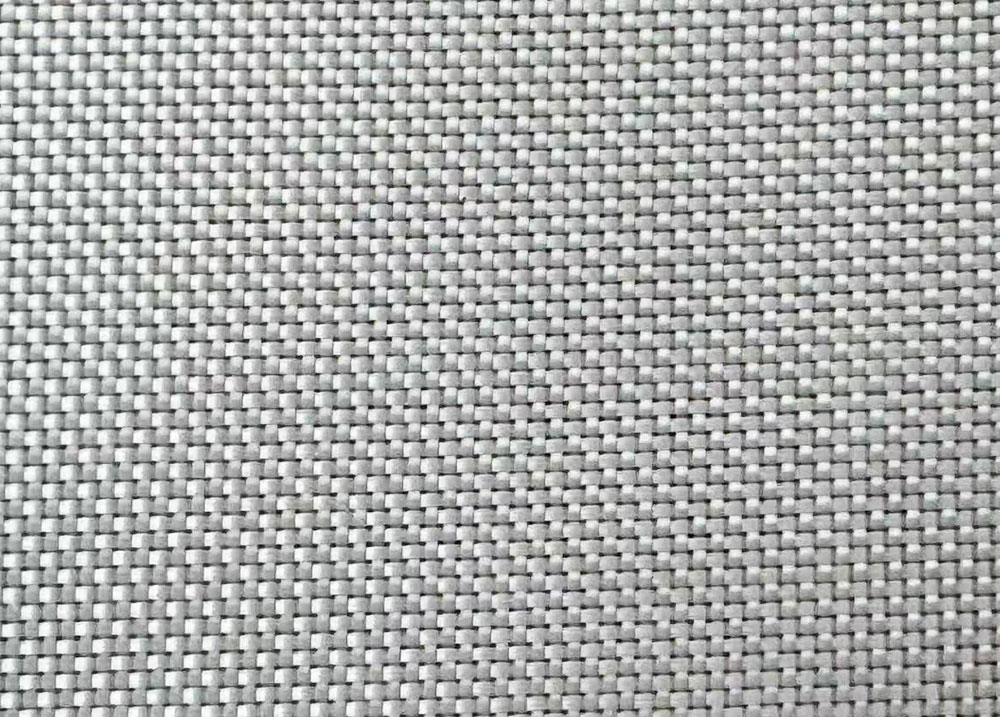

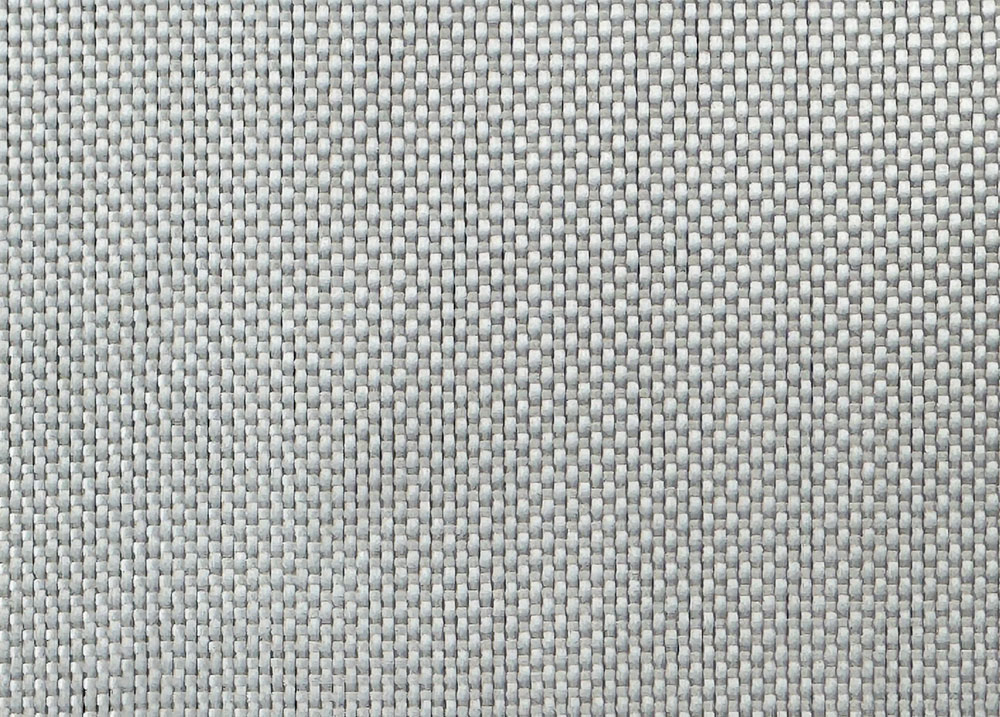

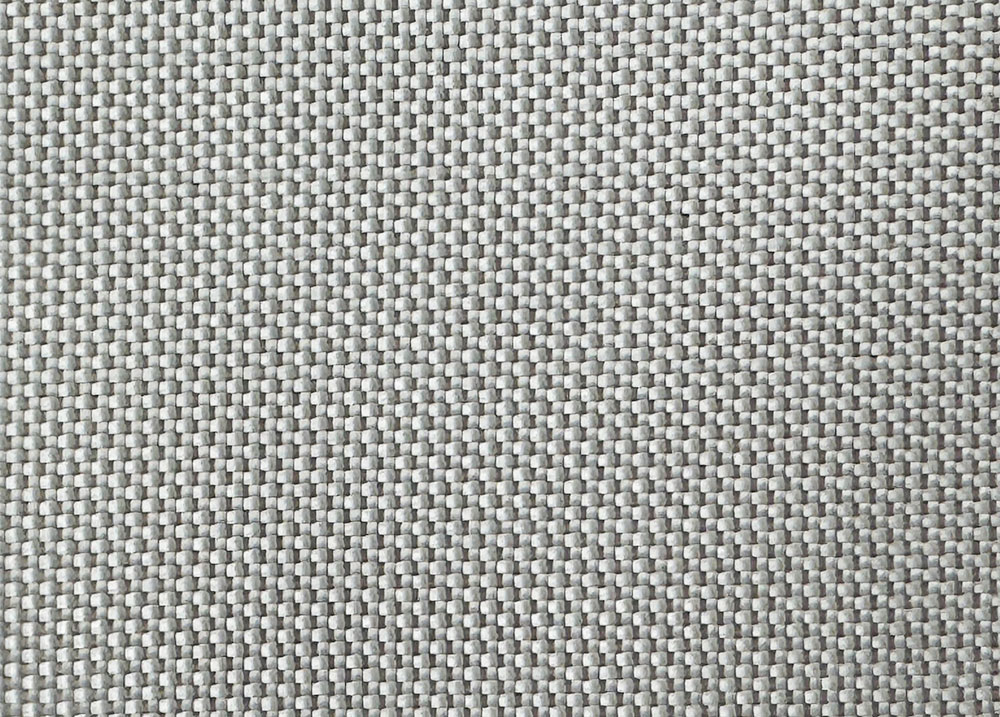

Basic Principles of Glass Fabric Weaving

Raw Material Preparation

Fiberglass yarns are made by melting glass and drawing it into fine fibers, which are then sized and twisted into yarns suitable for weaving.

The strength, fineness, and uniformity of the yarns directly affect the quality of the woven fabric.

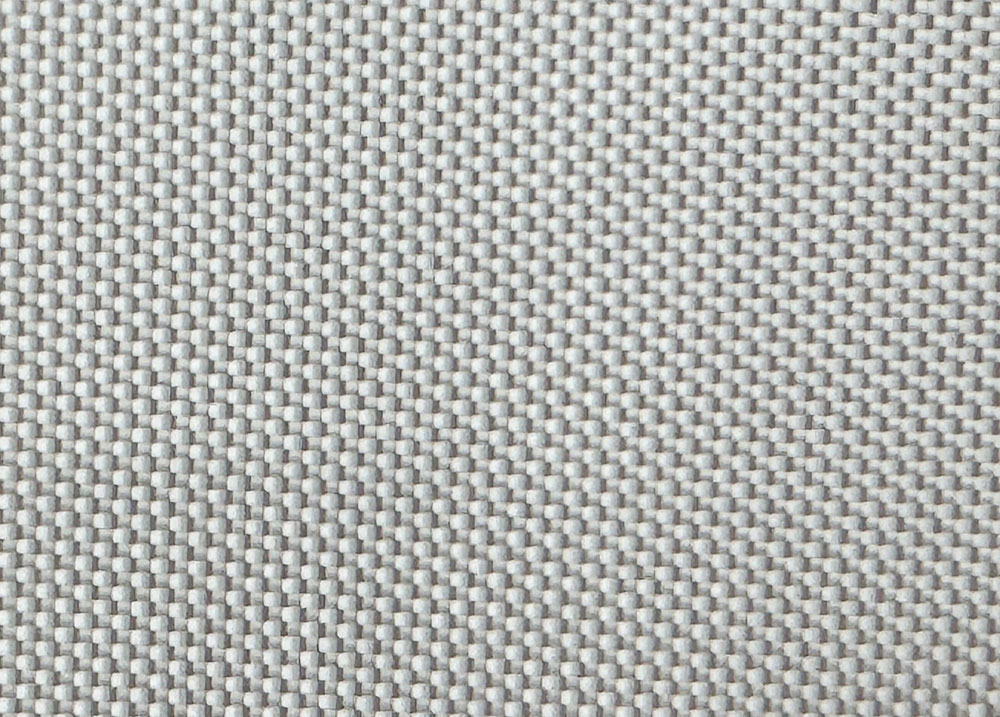

Warp and Weft Yarn Arrangement

- Warp yarns: These are the longitudinal yarns held under tension on the loom, providing strength along the length of the fabric.

- Weft yarns: These are the transverse yarns inserted between the warp yarns during weaving, providing strength across the width.

Weaving Process

The weaving machine alternately raises and lowers the warp yarns to create a shed (space), through which the weft yarn is inserted to interlace the yarns.

Common weave patterns include:

- Plain Weave: Warp and weft yarns cross alternately, resulting in a strong and balanced fabric.

- Twill Weave: Yarn interlacing creates diagonal patterns, producing a softer and more flexible fabric.

- Satin Weave: Weft yarn floats over several warp yarns, creating a smooth surface and higher strength.

Tension and Density Control

Proper tension on warp and weft yarns is maintained to ensure fabric density and dimensional stability.

Fabric density (number of yarns per unit area) influences mechanical strength and weight.

Post-Treatment

After weaving, the fabric may undergo heat-setting, sizing, or coating to enhance strength, abrasion resistance, and bonding with resin matrices.