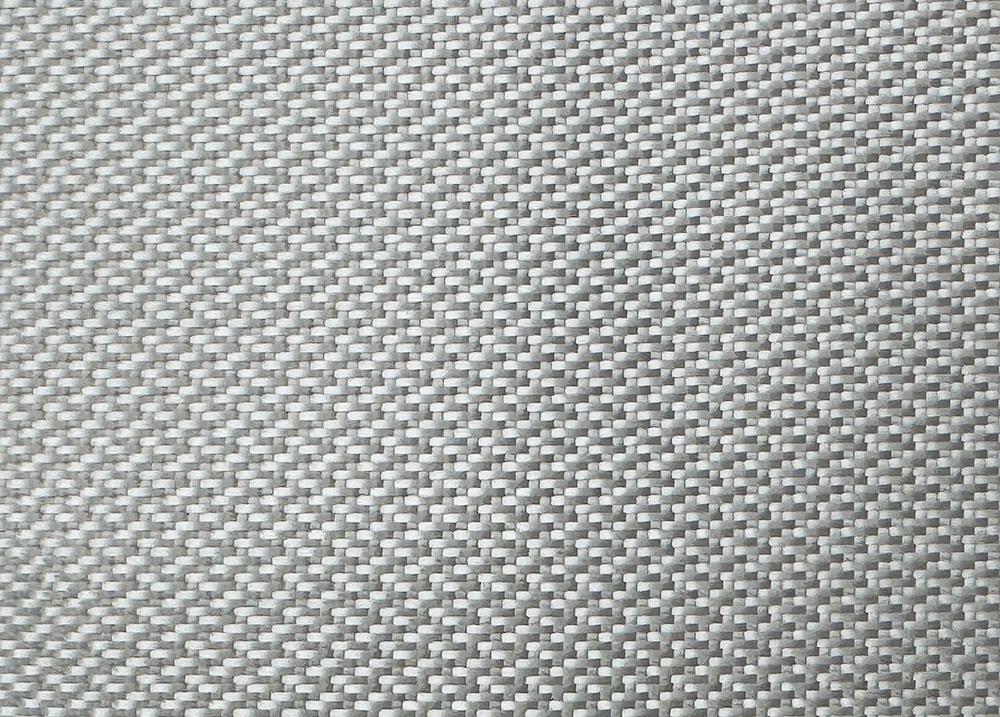

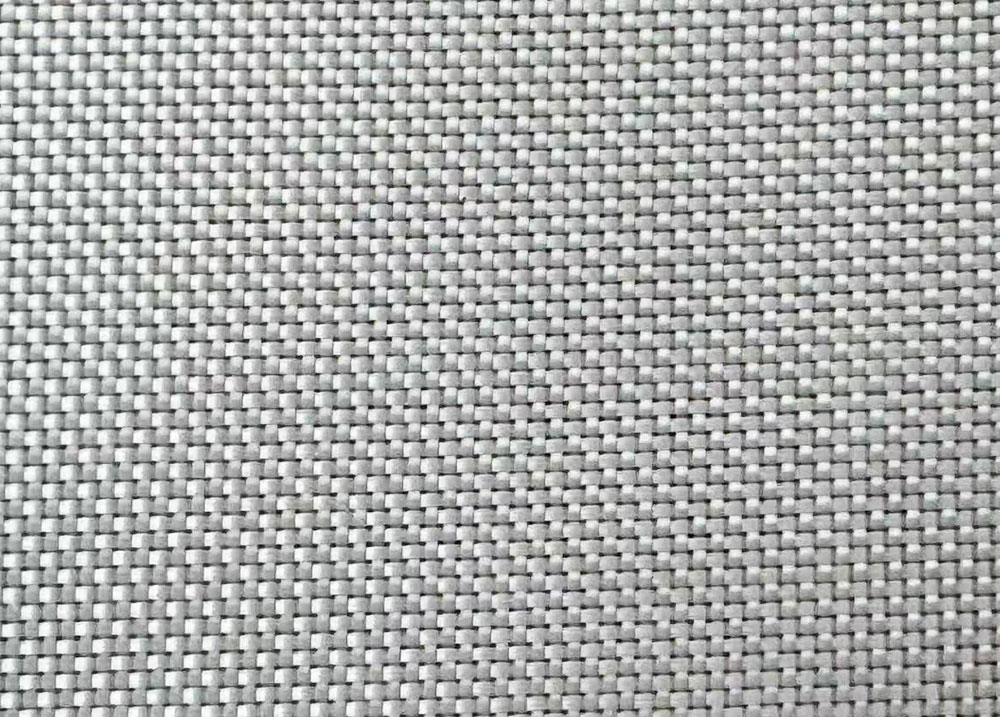

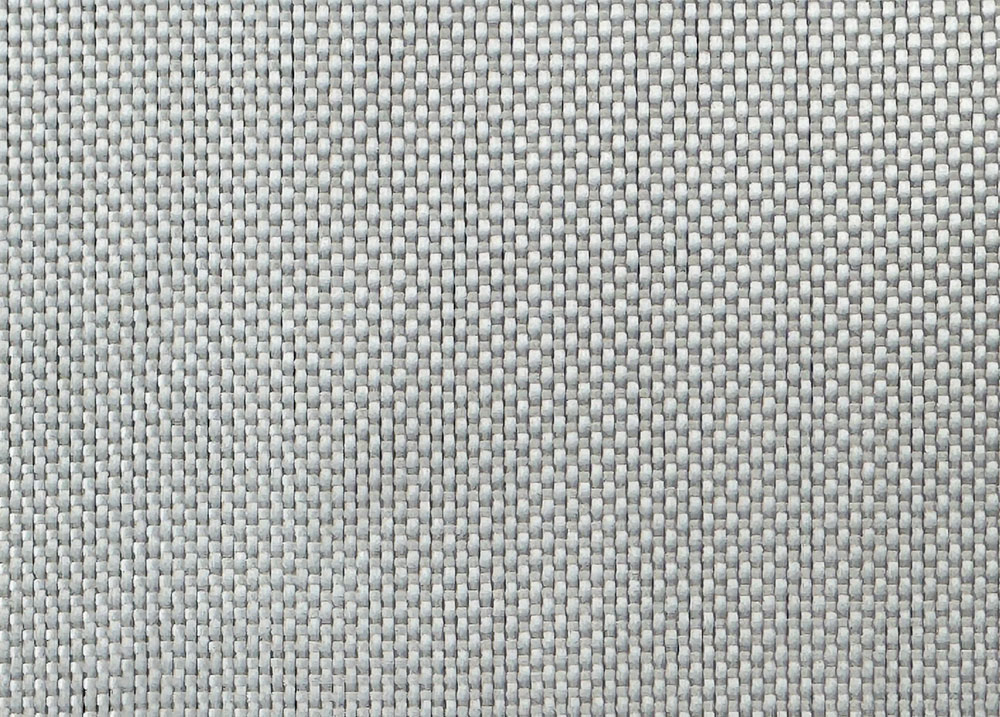

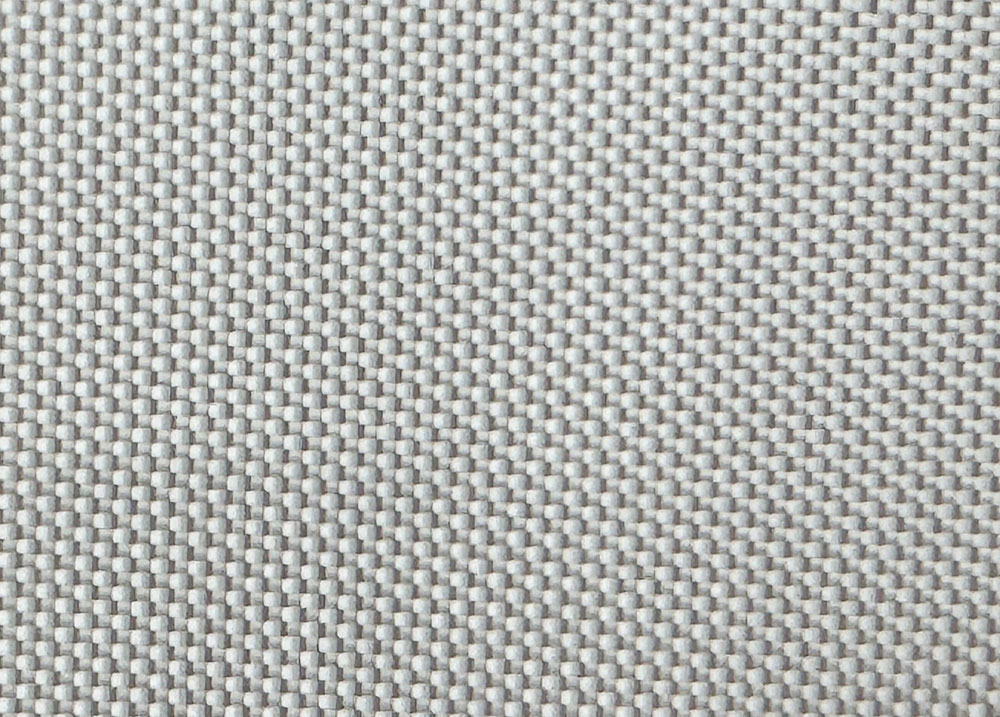

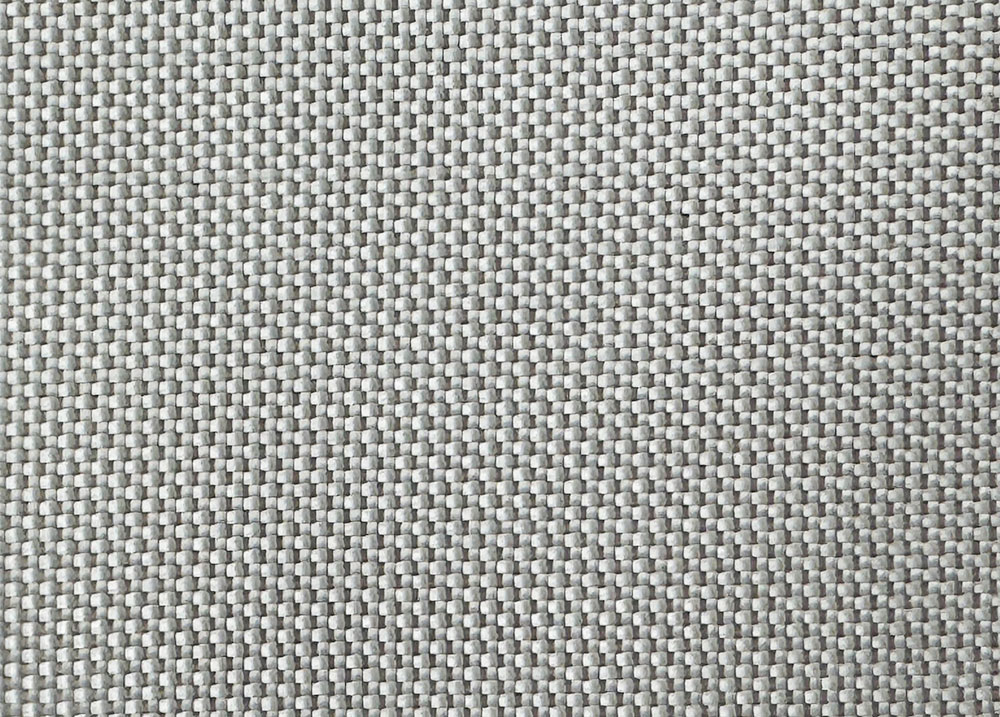

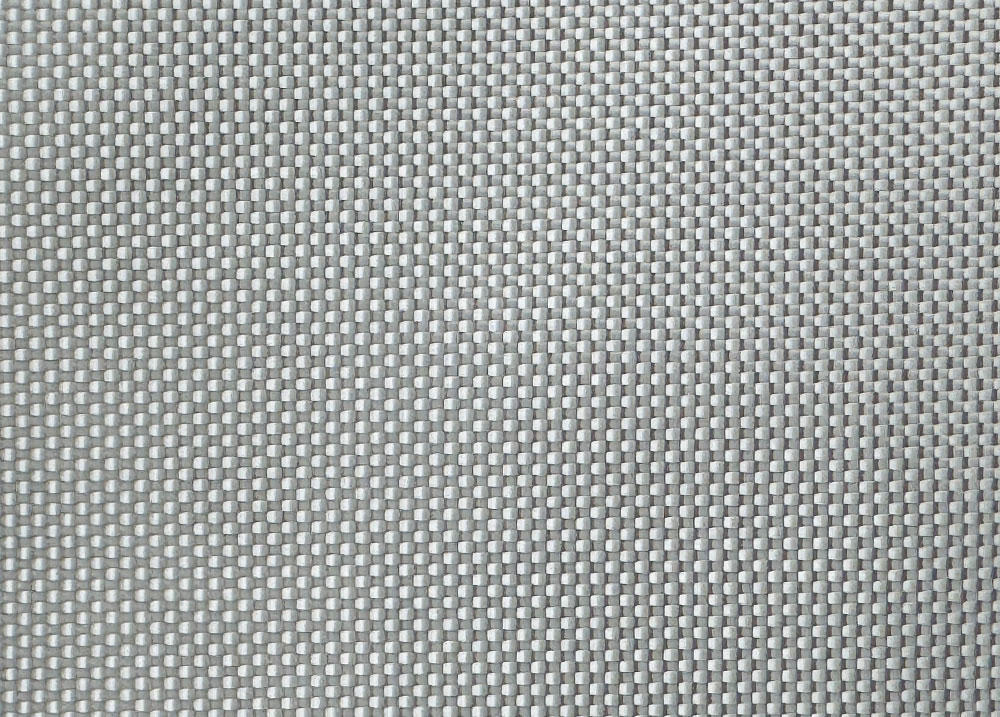

C/E-Glass Fiberglass Woven Roving

· Compatible Resins: Polyester, Epoxy, Vinyl Ester

Key Features

· High tensile strength and impact resistance

· Open weave for easy and even resin impregnation

· Dimensional stability for structural applications

· Conforms well to complex shapes and contours

· Suitable for both hand lay-up and machine processing

Applications

· Marine: Hulls, decks, and load-bearing components

· Automotive: Structural reinforcements and composite panels

· Industrial: Tanks, ducts, housings, and composite molds

Difference between C-glass and E-glass

| Aspect |

C-Glass (Chemical Glass) |

E-Glass (Electrical Glass) |

| Primary Use |

Designed for chemical resistance, especially against acids and corrosive environments |

Designed for electrical insulation and structural applications |

| Composition |

Higher chemical durability; typically contains higher amounts of boron and silica, lower alkali content |

Lower alkali content; optimized for electrical insulation properties and mechanical strength |

| Corrosion Resistance |

Excellent resistance to acidic and chemical environments |

Moderate chemical resistance; less resistant than C-Glass |

| Electrical Properties |

Poor electrical insulation properties compared to E-Glass |

Excellent electrical insulating properties |

| Mechanical Strength |

Good strength, but generally lower than E-Glass |

High tensile strength and stiffness |

| Typical Applications |

Chemical tanks, pipelines, corrosion-resistant coatings |

Electronics, electrical insulation, composites like fiberglass-reinforced plastics |

| Cost |

Generally more expensive due to specialized composition |

Generally more cost-effective and widely used |

In summary, C-Glass is preferred when corrosion resistance is critical, especially in harsh chemical environments. E-Glass is the standard glass fiber for most structural and electrical insulation applications due to its high strength and good dielectric properties.