Few fabrics strike the balance between strength, stability, and adaptability quite like polyester woven fabric. It’s widely used—often quietly—in everything from filtration systems to protective covers, and from coated substrates to structural reinforcement layers. But what exactly makes this material so popular in demanding industrial environments? In this article, we’ll take a closer look at what polyester woven fabric is, why it's preferred for industrial use, and how to maintain it for long-term performance.

What is Polyester Woven Fabric?

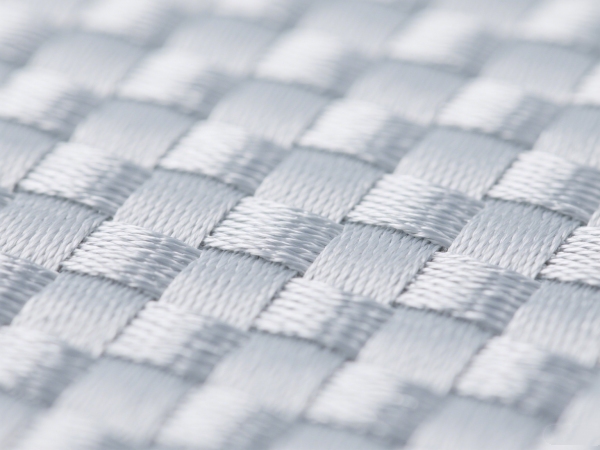

Polyester woven fabric is a textile material made by interlacing high-strength polyester yarns in a traditional warp and weft weave. The result is a stable, durable fabric that resists stretching and distortion under stress. Unlike knitted fabrics, which are soft and elastic, woven fabrics offer dimensional stability and mechanical rigidity—traits that are crucial for industrial applications.

Polyester, as a fiber, brings several intrinsic advantages to the table: it's resistant to moisture, chemicals, UV rays, and heat to a certain degree. When woven into a tight structure, it becomes a reliable substrate for lamination, coating, or standalone use in industrial-grade environments.

Key Properties for Industrial Use

The reason polyester woven fabric continues to be widely adopted across industries lies in its performance. Here are the core characteristics that make it suitable for heavy-duty environments:

High Tensile Strength: Withstand tension and mechanical stress without deformation or tearing.

Dimensional Stability: Maintains shape even after long-term use under pressure or weight.

Resistance to Chemicals and Moisture: Performs well in environments exposed to water, oils, and mild acids/alkalis.

UV and Weather Resistance: When treated or coated, it holds up well under prolonged outdoor exposure.

Thermal Tolerance: Can endure moderately high temperatures, especially when paired with appropriate coatings.

Low Stretch and Shrinkage: Critical for applications requiring consistent shape and tension over time.

Applications of Polyester Woven Fabric

Industrial polyester woven fabrics are used in a wide range of sectors. Some of the most common and essential applications include:

PVC or PU Coated Base Fabric: Used in tents, tarpaulins, inflatables, and membrane structures.

Filtration Media: Acts as a support layer for liquid or air filtration systems.

Reinforcement Layers: Integrated into conveyor belts, rubber sheets, or flexible tanks to enhance strength.

Industrial Covers & Curtains: Ideal for protecting equipment from dust, UV, or weather exposure.

Water Containment Liners: Commonly used as the base fabric for collapsible water tanks and bladders.

Protective Wraps: For wrapping large machinery, pipe insulation, or structural elements on job sites.

Its combination of form, function, and reliability makes it a go-to fabric in both permanent installations and temporary setups.

Maintenance and Lifespan

While polyester woven fabric is engineered for longevity, proper care extends its useful life and maintains performance. Here are practical tips for upkeep:

Avoid Sharp Bending or Folding: This helps prevent fiber fatigue and micro-damage along folds.

Store in Dry, Cool Areas: Keep the fabric away from prolonged humidity or direct sunlight when not in use.

Clean Gently: Use mild soap and water for cleaning; avoid harsh solvents unless the coating allows it.

Inspect Regularly: Check for abrasions, edge fraying, or coating delamination, especially in load-bearing zones.

Depending on the specific use case and treatment (e.g., coated vs. uncoated), polyester woven fabric can last anywhere from 3 to 10 years, or even longer in controlled environments. UV-treated and flame-retardant versions generally offer better longevity under harsh conditions.

Industrial polyester woven fabric is not just another textile—it’s a technical material designed to perform where other fabrics fail. Its strength, adaptability, and resistance to harsh environments make it a top choice across multiple industries. Whether you're sourcing it for filtration, flexible structures, or heavy-duty coverings, understanding its properties helps you choose wisely—and maintain performance over time.