Fiberglass may not look like much at first glance—lightweight, non-metallic, and often tucked behind layers of concrete or resin. But when it comes to strengthening structures, this material works hard behind the scenes. If you're reinforcing a concrete slab, a plastic component, or even a water tank, fiberglass has become a trusted companion across industries. So, what's the real purpose of fiberglass reinforcement, and why do so many professionals rely on it today? Let’s break it down.

What is Fiberglass Reinforcement?

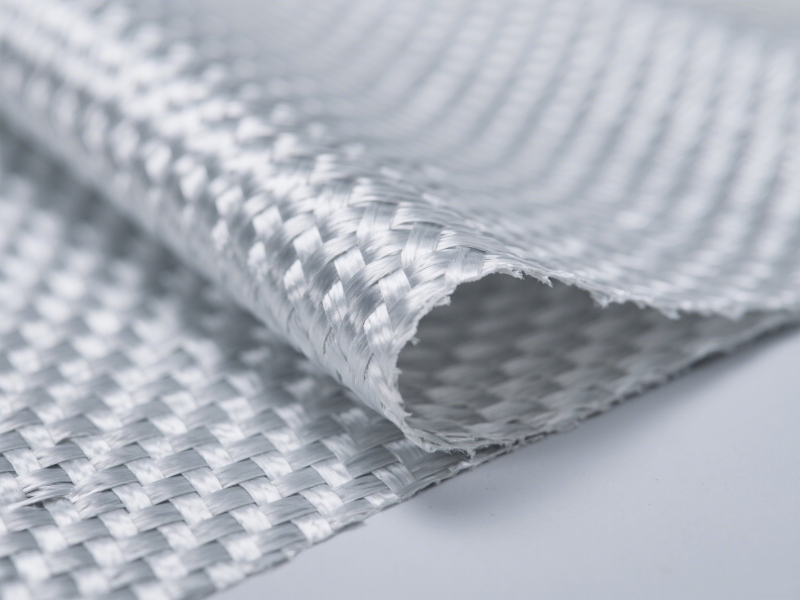

Fiberglass reinforcement refers to the use of glass fibers to strengthen various materials such as concrete, plastic, asphalt, or plaster. These glass fibers are typically woven into mats, chopped into strands, or formed into rods or mesh—each suited for different types of reinforcement.

Unlike traditional reinforcements like steel, fiberglass does not corrode or conduct electricity. It's made by melting silica-based glass and drawing it into fine filaments, which are then processed into different forms depending on the end use. It’s not just one type of material but rather a family of reinforcement products with a shared backbone: strength, flexibility, and chemical resistance.

Advantages of Fiberglass for Reinforcement

Fiberglass has been adopted in many fields because of its practical, performance-driven benefits. Here are some of the key reasons professionals choose fiberglass over other materials:

Lightweight but Strong

Don’t let its lightness fool you. Fiberglass has a high strength-to-weight ratio, making it ideal for applications where weight matters but strength can’t be compromised.

Corrosion Resistance

Unlike steel, fiberglass doesn’t rust or degrade in moisture or chemically aggressive environments. This makes it perfect for coastal, underground, or chemical applications.

Non-Conductive & Non-Magnetic

Fiberglass is a safe choice in electrical or sensitive magnetic environments, where steel might interfere.

Low Thermal Conductivity

Excellent for applications that require temperature insulation, as fiberglass doesn't transfer heat easily.

Easy to Handle & Install

Lightweight and non-brittle, fiberglass materials are easier to cut, transport, and install on-site, reducing labor and equipment costs.

Design Flexibility

Available in different forms—mesh, rods, rebar, chopped fibers—fiberglass can be tailored to a wide range of material systems.

Where is it Commonly Used?

Fiberglass reinforcement shows up in more places than most people realize. It’s used both in large-scale construction and in everyday products. Common applications include:

Construction Industry

Used to reinforce concrete panels, roadways, precast walls, and insulation panels. Also popular in bridge decks, tunnels, and coastal structures.

Plastic & Polymer Composites

Integrated into thermoplastics and thermosets to improve tensile strength and durability—ideal for automotive parts, tanks, and consumer goods.

Roofing & Waterproofing Membranes

Reinforced membranes resist cracking and improve longevity of roofing systems.

Industrial Flooring & Panels

In settings with high foot traffic or chemical exposure, fiberglass helps maintain strength and performance over time.

Pipeline and Ducting Systems

Especially in environments where corrosion or pressure is a concern.

Marine & Aerospace Applications

Fiberglass materials are prized for being lightweight and corrosion-resistant—two critical needs in boats and aircraft.

Is Fiberglass Reinforcement Worth it?

For many professionals and project managers, the answer is a resounding yes—but context matters. Fiberglass reinforcement is usually more expensive than traditional options like plain steel or plastic fillers, but its lifecycle value often outweighs the upfront cost. Here’s why:

1. In corrosive environments, fiberglass can outlast steel by years or even decades.

2. Its lighter weight means lower transport and labor costs—a big deal in large projects.

For projects where safety, insulation, or electromagnetic neutrality is essential, fiberglass is not just worth it—it’s the only practical option.

That said, it’s not a universal solution. In ultra-high load-bearing situations where compressive strength is critical, steel might still be the better choice. But for most modern reinforcement needs—especially where corrosion, weight, or long-term durability is at play—fiberglass more than holds its own.

So, what’s the purpose of fiberglass reinforcement? It's about providing reliable, lightweight strength where traditional materials fall short—especially in environments where corrosion, conductivity, or heavy labor could compromise a structure. It’s not just a substitute for steel; it’s a smarter, forward-looking solution for modern challenges in construction, manufacturing, and beyond.

If you're considering fiberglass reinforcement for your next project, it may just be the behind-the-scenes upgrade your design needs. Strong, safe, and built to last—it’s a material that speaks softly but carries a big load.