Aramid Mesh Fabric, as a high-performance material that combines high strength, heat resistance and light weight, is widely used in protective equipment, industrial filtration, composite reinforcement and other fields. But have you ever wondered how this fabric evolves from a single fiber into a sophisticated mesh fabric?

This article will provide you in-depth understanding of the manufacturing process of aramid mesh fabric, from the selection of raw materials to the mesh weaving process, step by step, to unveil the secrets behind its technology.

What is Aramid Mesh Fabric?

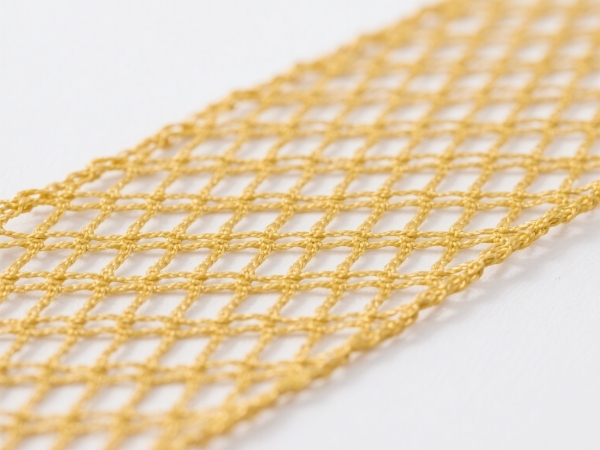

“Aramid” stands for Aromatic Polyamide, best known for Kevlar® and Twaron®. They are widely used in high-performance materials for their excellent cut resistance, flame retardancy, corrosion resistance and tensile strength. The term “mesh fabric” refers to a mesh fabric with a porous structure, so aramid mesh fabric is essentially a mesh high-strength fabric made from woven aramid yarns.

Aramid Mesh Fabric Manufacturing Process Explained

The Birth of Aramid Fibers

The first step in Aramid mesh fabric is the manufacture of aramid fibers. This is usually done by a technique called **Dry-Jet Wet Spinning**, in which an aromatic polyamide polymer is processed into long, thin, continuous fibers. These fibers have a very high specific strength and stable molecular structure, making them ideal for the manufacture of high-performance yarns.

Fibers into weavable yarn

Next, the aramid fibers are gathered into tows, which are then twisted in a certain way to form the aramid yarn for weaving. Depending on the application, the yarns can also be coated to enhance their waterproof, corrosion-resistant or adhesive properties.

How the mesh fabric structure is woven

Aramid mesh fabric can be made by **weaving** or **knitting**, depending on the strength and flexibility requirements of the target application.

Woven Aramid Mesh

Using a conventional loom, warp and weft yarns are interlaced at regular angles to form a stable mesh structure. This structure has excellent dimensional stability and tensile strength and is often used for protective fabrics, industrial screens and composite reinforcements.

Knitted Aramid Mesh

Knitted technology is utilized to loop yarns together to form a mesh with a certain degree of elasticity. The knitted structure is softer and suitable for flexible protection, filtration layers and isolation layers in composite materials.

Post-processing and sizing

After weaving, aramid mesh can also be heat set** to stabilize the dimensions or coated (e.g., PTFE, silicone)** to enhance its chemical resistance and service life. The final product is usually supplied in rolls or cut sheets for easy customization.

Typical Application for Aramid Mesh Fabric

1. Bullet and cut resistant equipment: used in the manufacture of protective undershirts, cutting protective gloves, etc.

2. High temperature filtration and shielding: used in smoke filtration systems, welding shields, etc.

3. Aerospace composite reinforcements

4. Reinforcement materials for industrial construction: e.g., concrete reinforcing meshes

Why Choose Aramid Mesh Fabric?

Lightweight and Strong: Stronger than steel, yet lightweight and controllable

Heat Resistant and Flame Retardant: Withstands temperatures over 400 degrees Celsius without melting

Chemically Resistant: Suitable for use in harsh industrial environments

Eco-Sustainable: Longer life of Aramid material, replacing traditional, multi-replacement fabrics

The manufacture of Aramid mesh fabric is not simply a “weave”, but a sophisticated process that combines materials science, engineering and application requirements. Whether you are involved in protective equipment manufacturing or composites engineering, understanding the manufacturing process will help you better select and apply this high-performance material.

If you are looking for high quality aramid mesh fabric manufacturer or customized service, welcome to contact us. Hoyan will provide you with professional solutions and technical support.