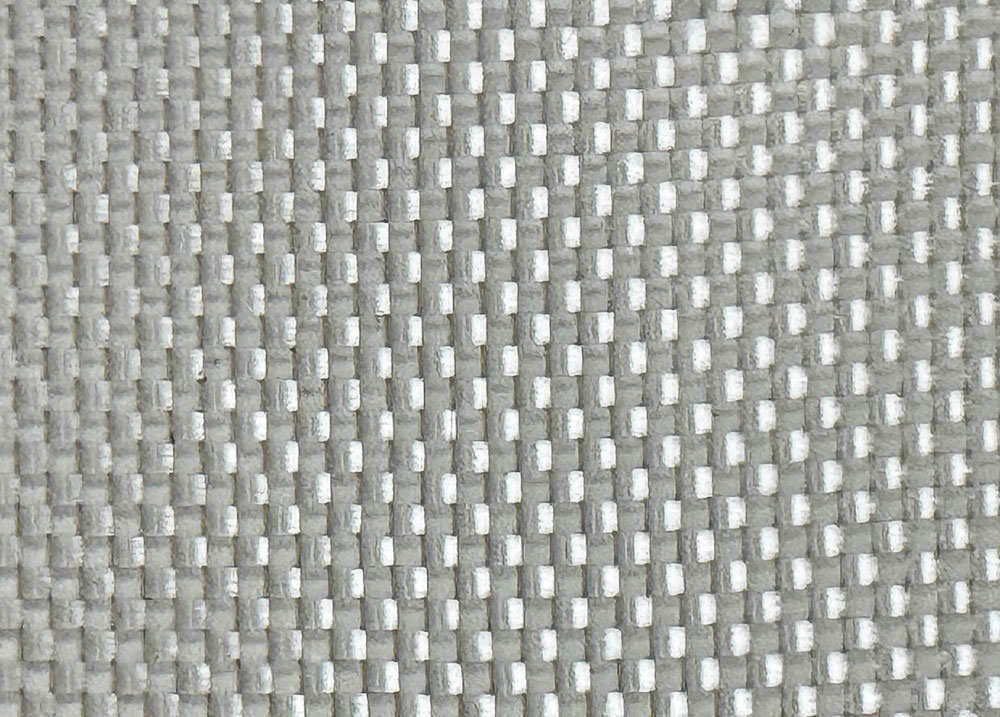

Industrial Polyester Woven Fabric

Key Features

· Exceptional strength and resilience for demanding industrial environments

· High resistance to wrinkling, shrinking, and fading

· Maintains a smooth, professional appearance

· Easy-care and low maintenance

Applications

· Protective covers and heavy-duty workwear

· Industrial upholstery and technical textiles

· Suitable for environments requiring long-lasting performance

Industrial Polyester Woven Fabric: Meeting Diverse Industrial Needs

Industrial polyester woven fabrics are designed to adapt to a wide range of industrial applications. By adjusting yarn density, fabric weight, and layer count, these fabrics can meet specific performance requirements.

1. Yarn Density

Higher yarn density increases tensile strength, durability, and abrasion resistance.

Lower density allows more flexibility and lighter weight for less demanding applications.

2. Fabric Weight (GSM)

Heavier fabrics provide extra strength and structural support for high-load or protective uses.

Lighter fabrics are ideal for coverings, drapes, or filtration applications where weight reduction is important.

3. Layer Count

Multiple layers enhance reinforcement, tear resistance, and dimensional stability.

Single-layer fabrics offer cost-effective solutions while maintaining essential performance.

4. Tailored Industrial Applications

High-density, heavy, multi-layer fabrics: Conveyor belts, industrial tarpaulins, protective coverings.

Medium-density fabrics: Filtration systems, machinery covers, outdoor industrial fabrics.

Low-density, lightweight fabrics: Packaging, temporary coverings, or flexible protective sheets.

By customizing yarn density, fabric weight, and layer count, industrial polyester woven fabrics provide versatile, durable, and tailored solutions for diverse industrial needs, ensuring optimal performance, efficiency, and cost-effectiveness.