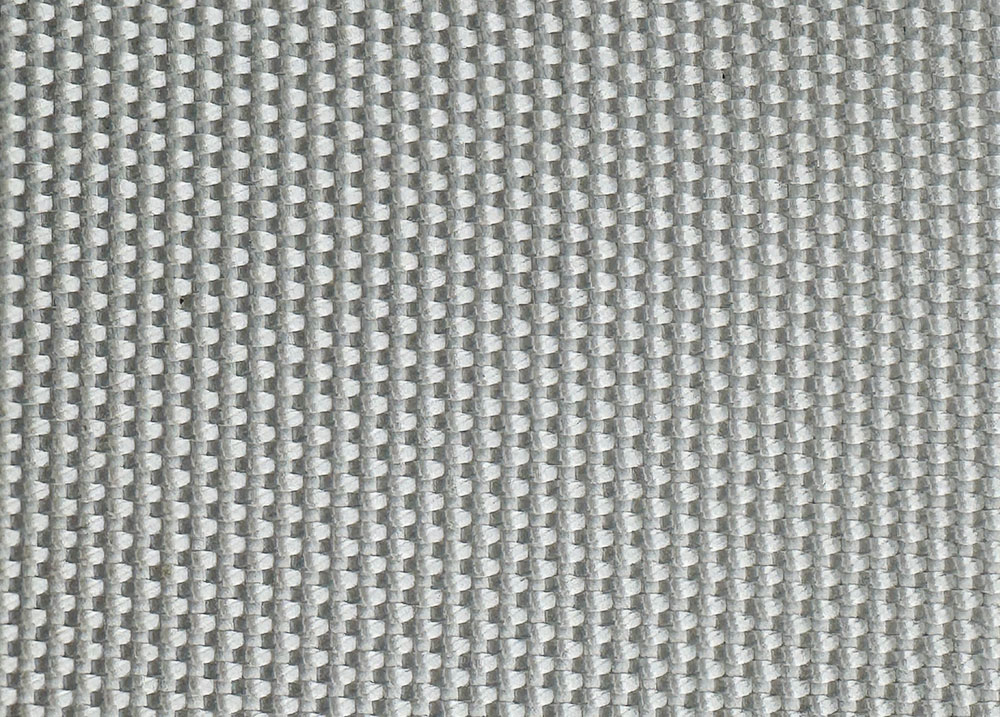

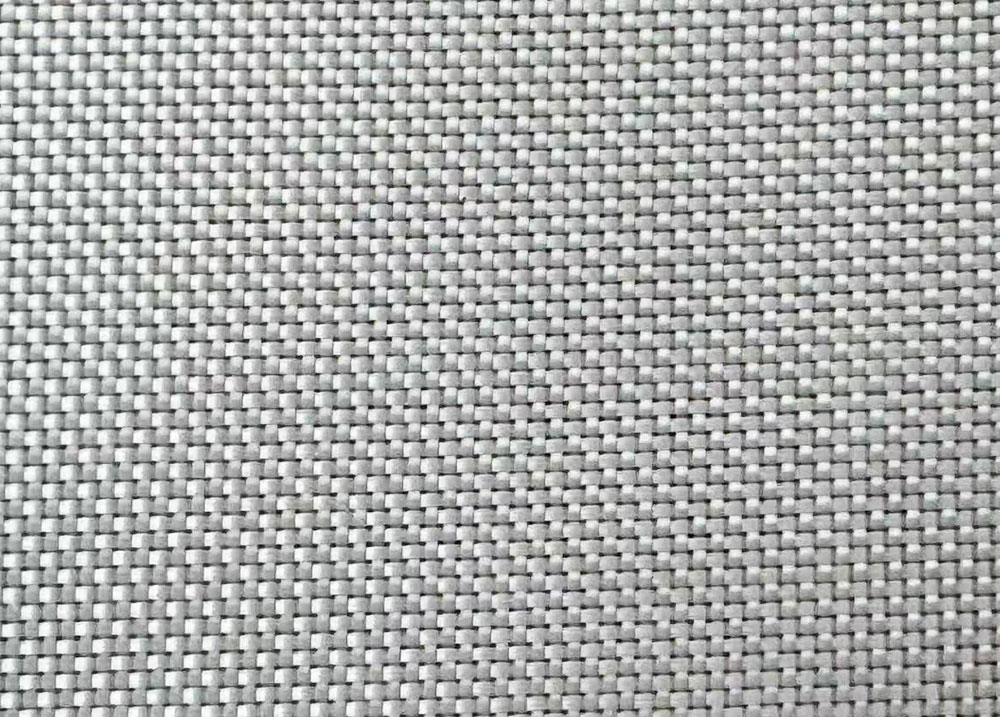

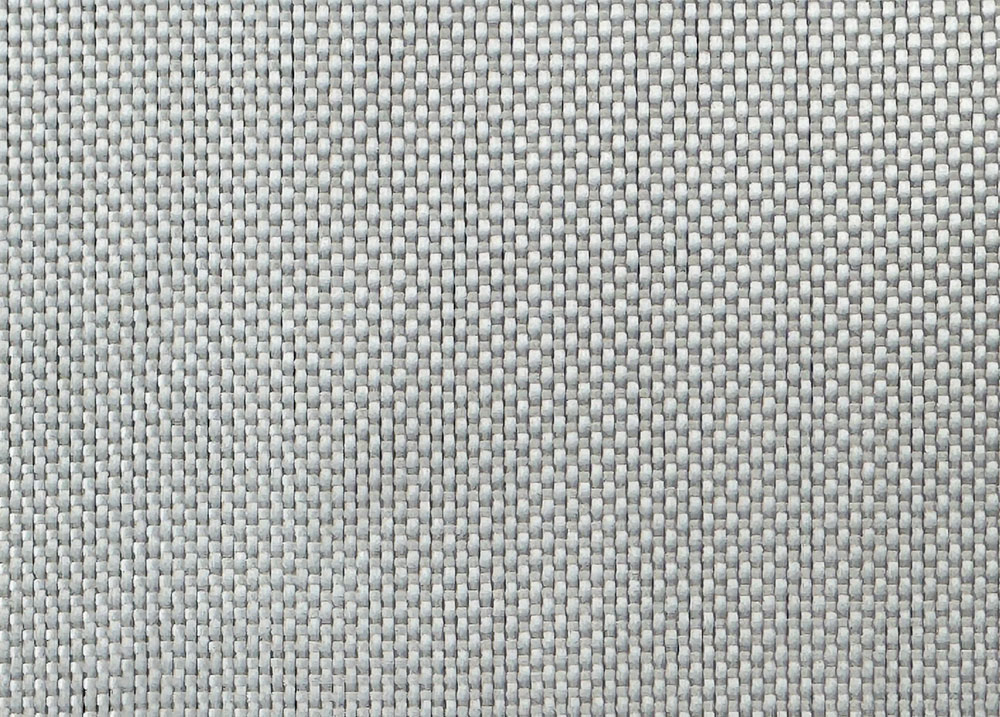

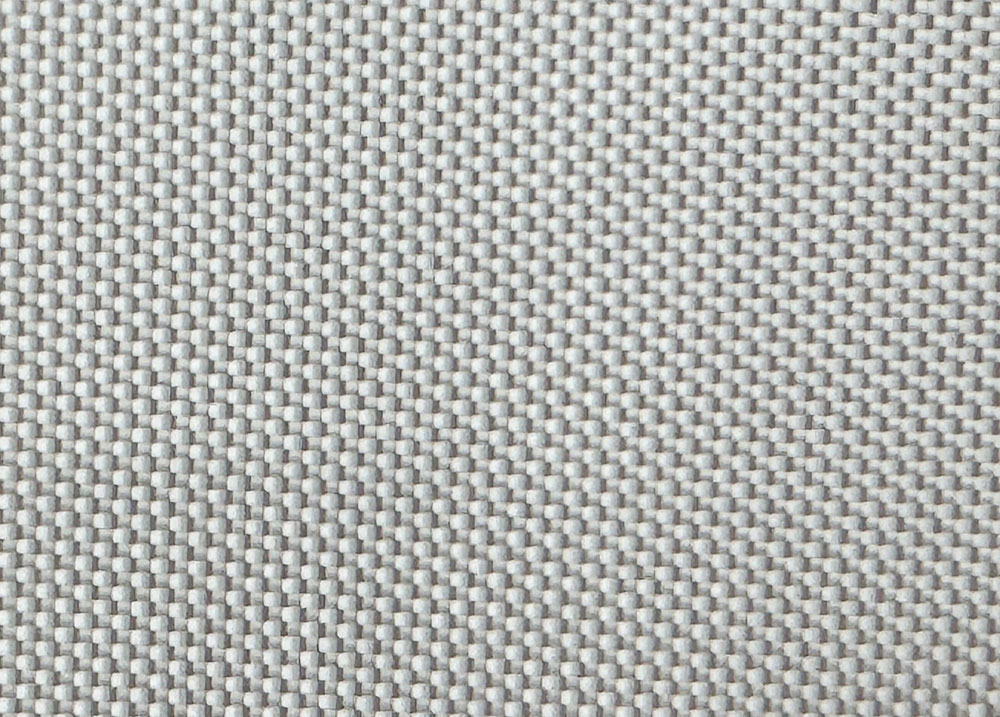

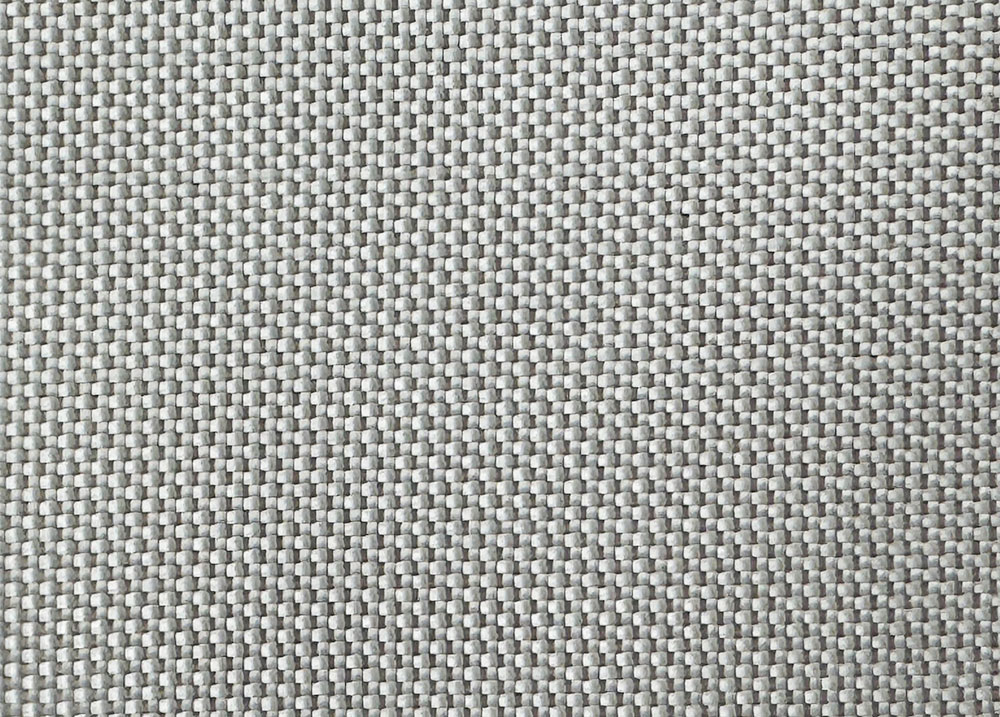

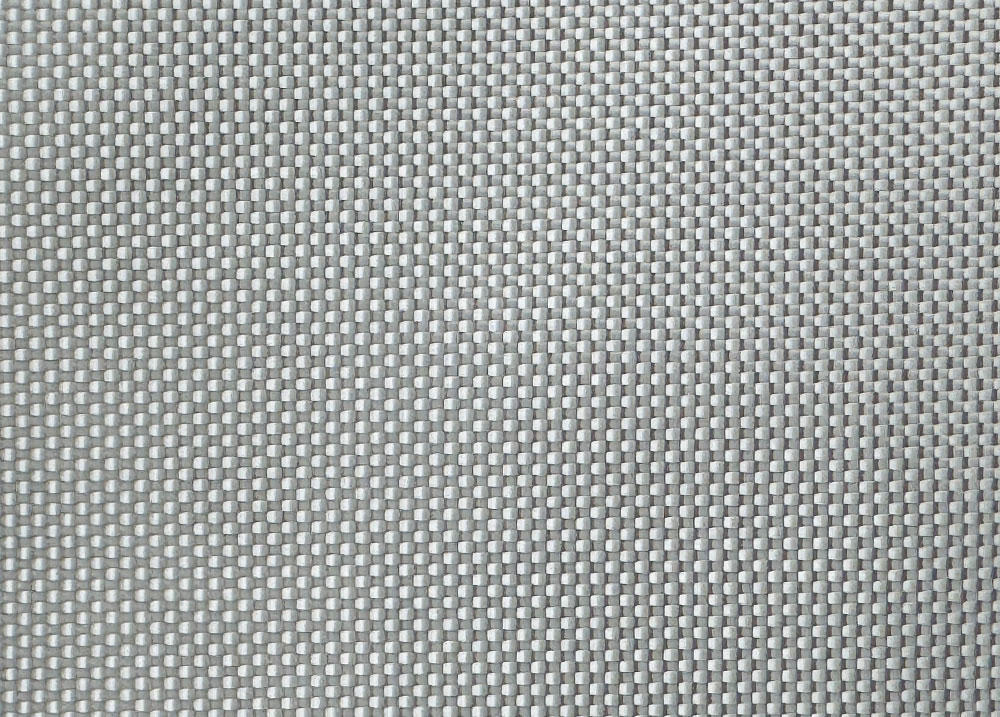

Woven Fiberglass Fabrics and Rolls

· Compatible Resins: Polyester, Epoxy, Vinyl Ester

Key Features

· Exceptional strength and durability for heavy-duty use

· Balanced weave for uniform strength in warp and fill directions

· Flexible yet robust for versatile applications

· Cost-effective solution for large-scale projects

· Manufactured to strict quality standards for consistent performance

Applications

· Marine: Hulls, decks, structural reinforcements

· Industrial: Tanks, panels, machinery housings

· Construction: Reinforcement of building materials and structural components

Fiberglass Rolls vs. Sheets: Applications and Convenience

1. Fiberglass Rolls

Fiberglass rolls are ideal for large-scale projects and continuous lamination processes. They are commonly used in:

▪ Boat hulls and decks

▪ Large FRP panels and tanks

▪ Industrial pipelines and ducts

Advantages: Rolls allow for custom length cutting, reduce material waste in continuous applications, and are convenient for storage and automated production.

2. Fiberglass Sheets

Fiberglass sheets are pre-cut panels that are best suited for small-scale projects, repairs, or precision work, such as:

▪ Patching damaged boats or machinery

▪ Creating small FRP components

▪ Targeted reinforcement in construction or industrial applications

Advantages: Sheets save preparation time, ensure consistent dimensions, and are easy to handle for manual work.

Choosing between rolls and sheets depends on the scale of the project, handling method, and efficiency requirements. Rolls offer flexibility and efficiency for large applications, while sheets provide convenience and precision for smaller or detailed work.