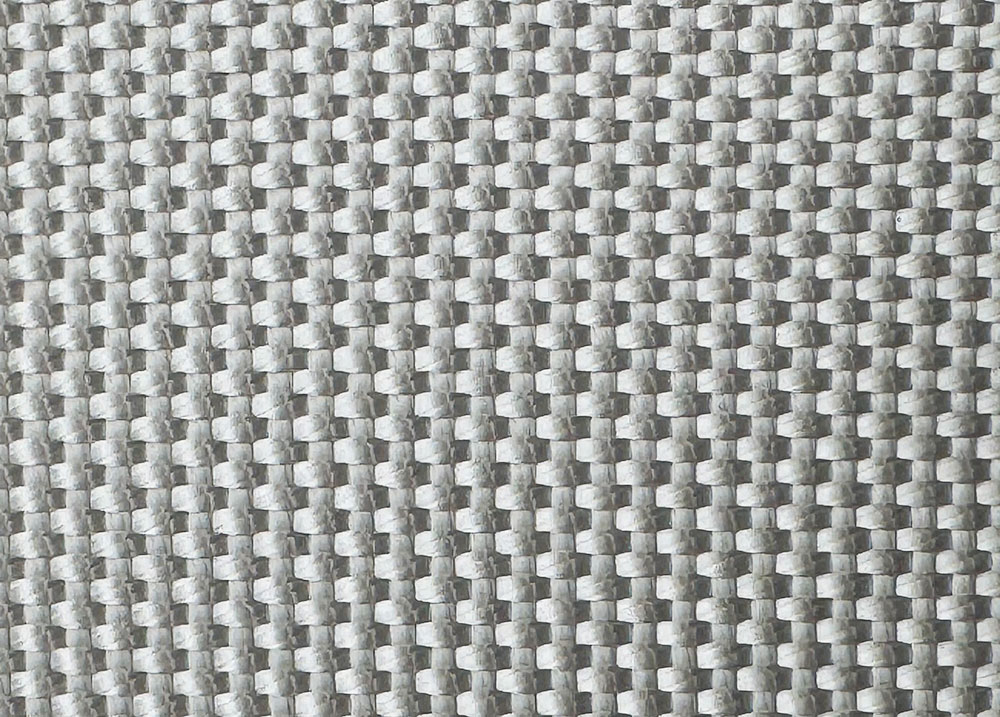

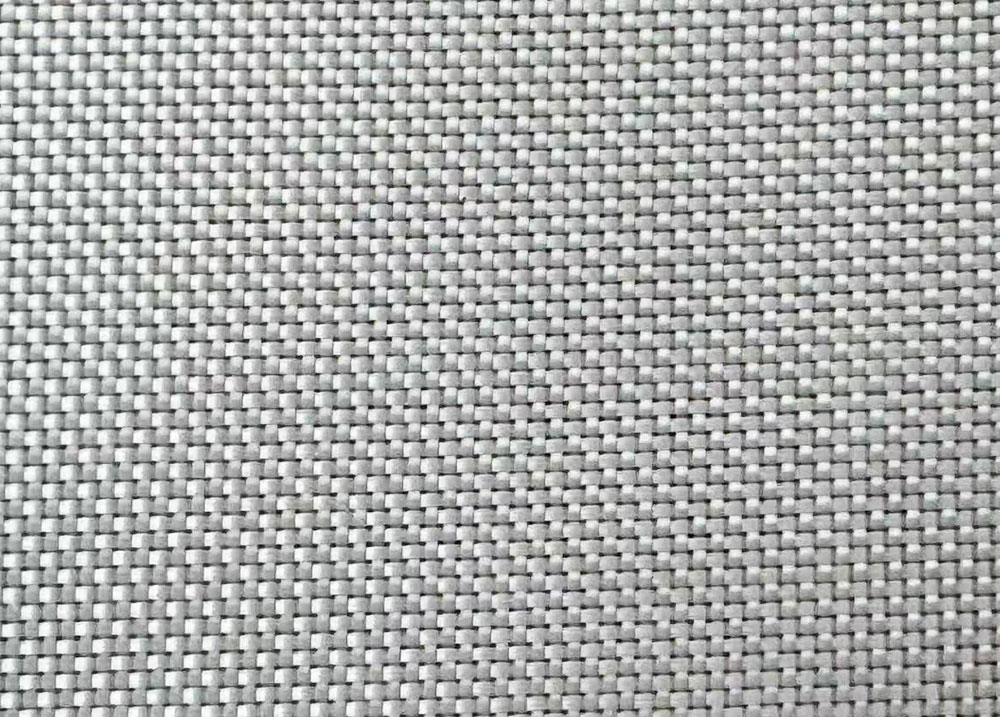

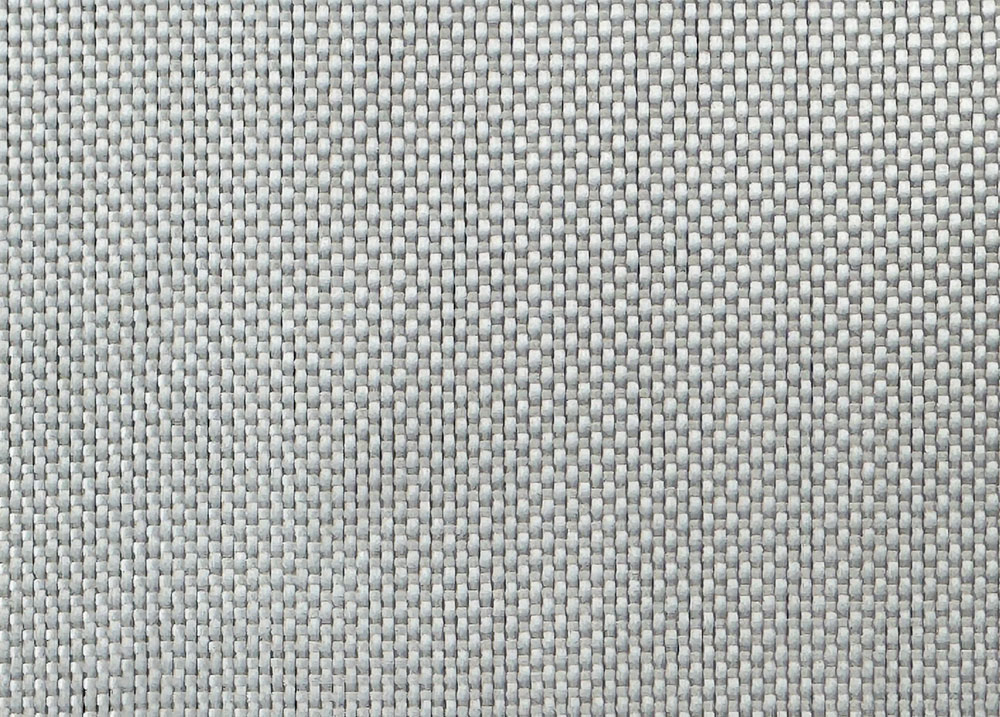

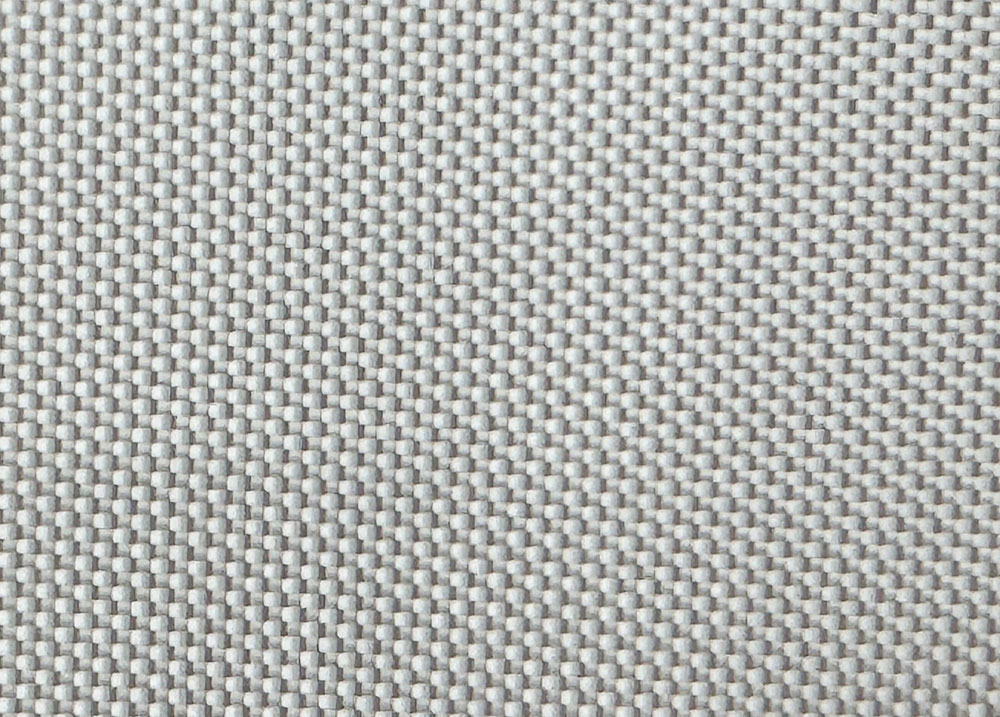

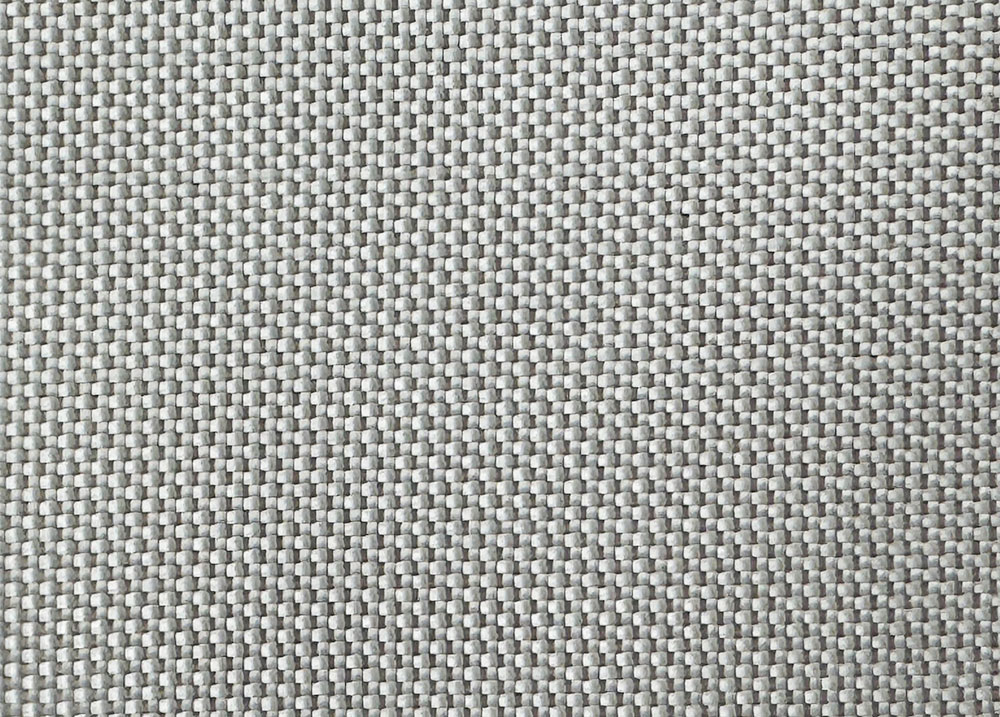

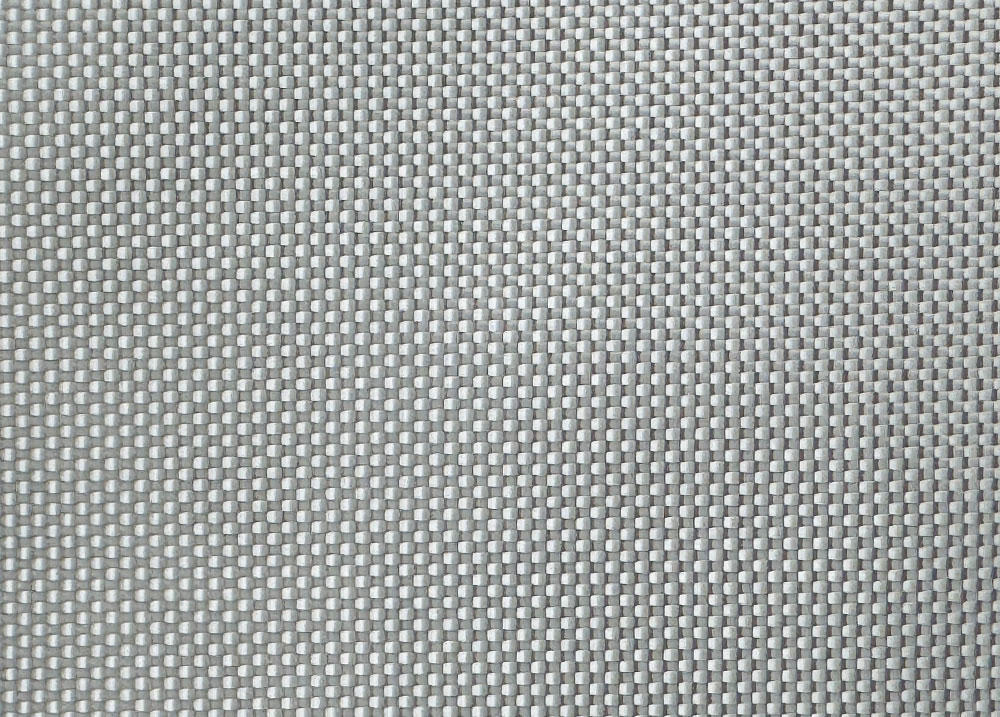

Fiberglass Fabric for FRP Products

· Compatible Resins: Polyester, Epoxy, Vinyl Ester

Key Features

· Designed for fiberglass-reinforced plastic (FRP) laminates and molds

· Superior strength and structural integrity for demanding applications

· Excellent resin permeability for thorough saturation

· Ideal for both manual lay-up and vacuum forming

· Consistently manufactured for reliable performance

Applications

· FRP Molding: Creation of custom molds and complex parts

· Structural Components: Panels, enclosures, and load-bearing parts

· Industrial Composites: Tanks, housings, and infrastructure elements

· High-Durability Products: Long-lasting, corrosion-resistant composites

What are FRP Products?

FRP products are Fiber Reinforced Plastic products, which are composite materials made by combining a polymer resin (such as polyester, vinyl ester, or epoxy) with a reinforcing fiber (commonly glass fiber, but also carbon or aramid).

The resin provides shape and chemical resistance, while the fibers give strength, stiffness, and durability. This combination makes FRP products lightweight, strong, corrosion-resistant, and versatile.

Common FRP products include:

1. Construction: FRP panels, roofing sheets, rebars, and gratings

2. Transportation: Car body parts, truck panels, and railway interiors

3. Marine: Boat hulls, decks, and repair laminates

4. Industrial: Chemical storage tanks, pipes, ducts, and covers

5. Consumer goods: Sports equipment, ladders, and protective helmets

In short, FRP products are widely used wherever high strength, low weight, and corrosion resistance are required.