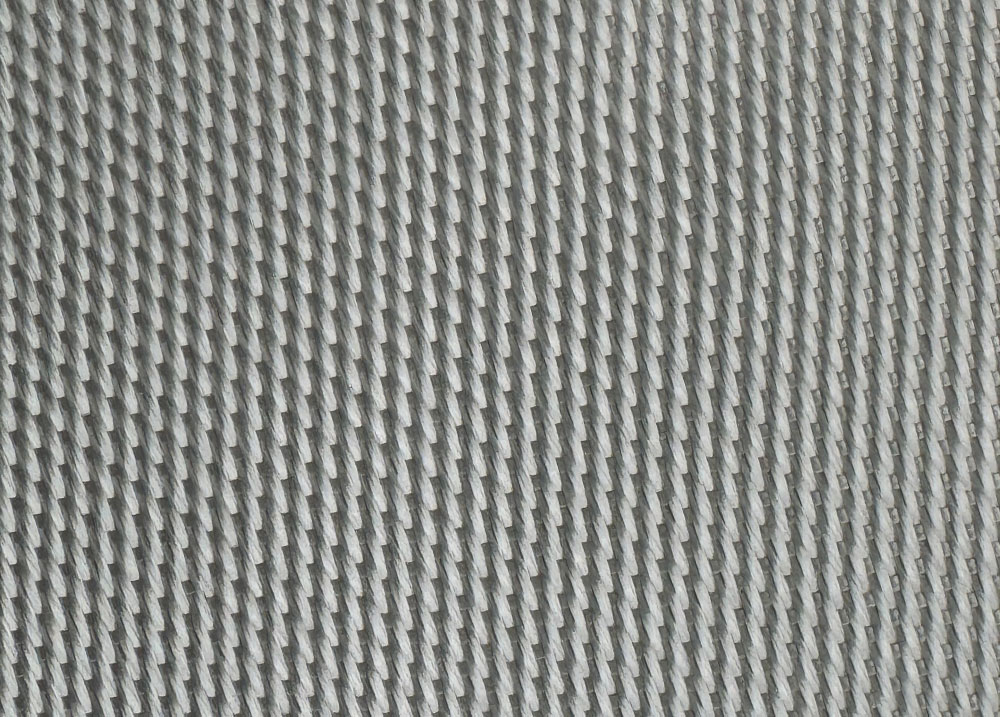

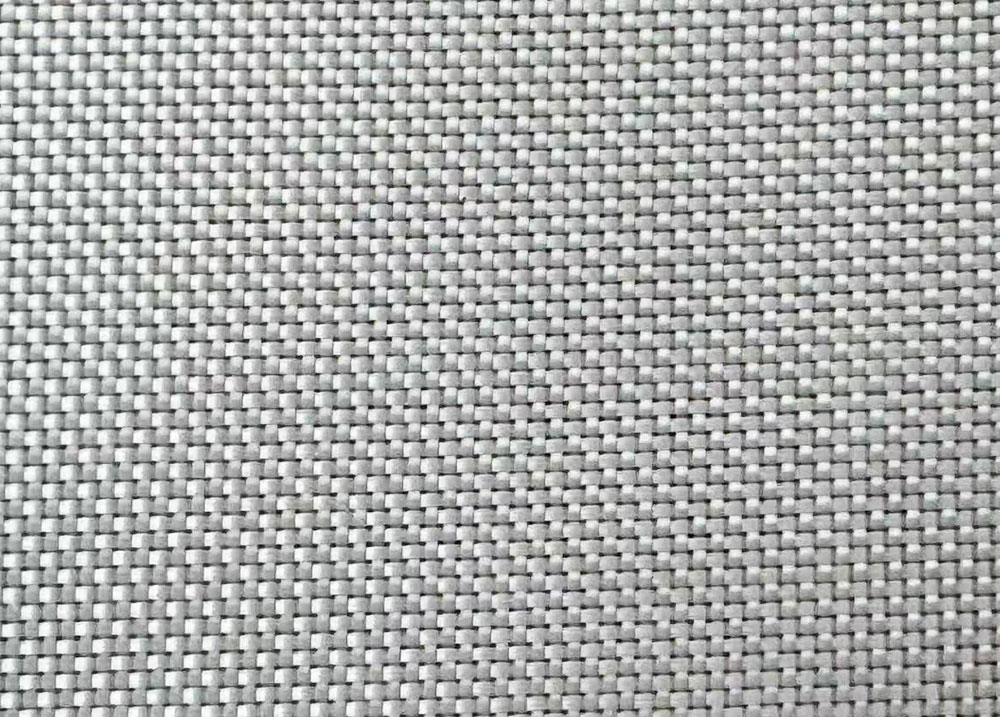

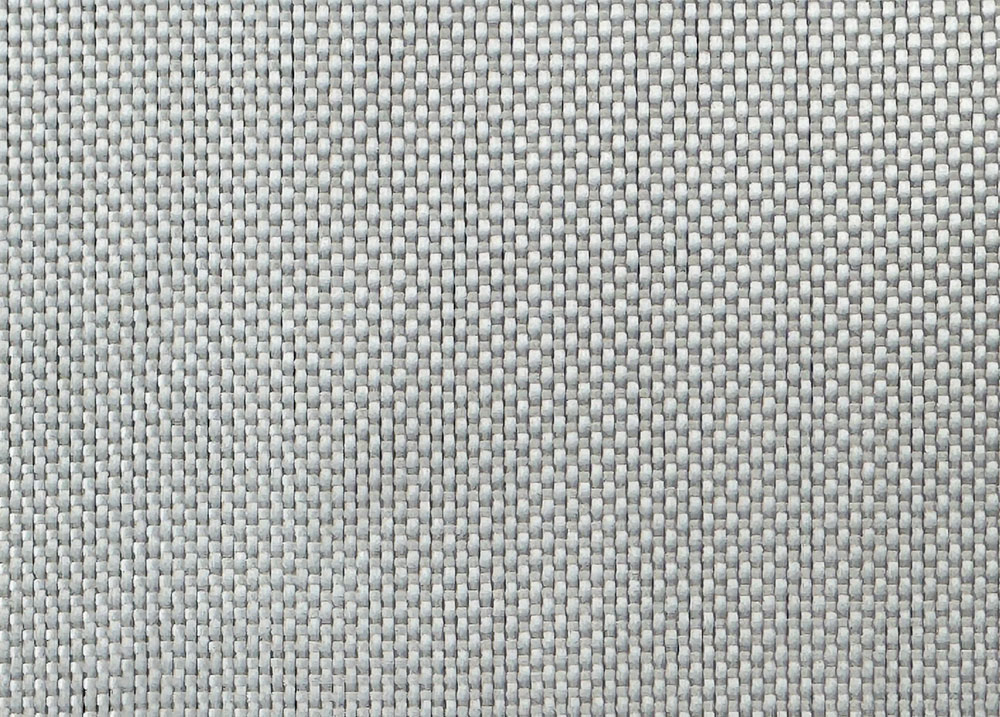

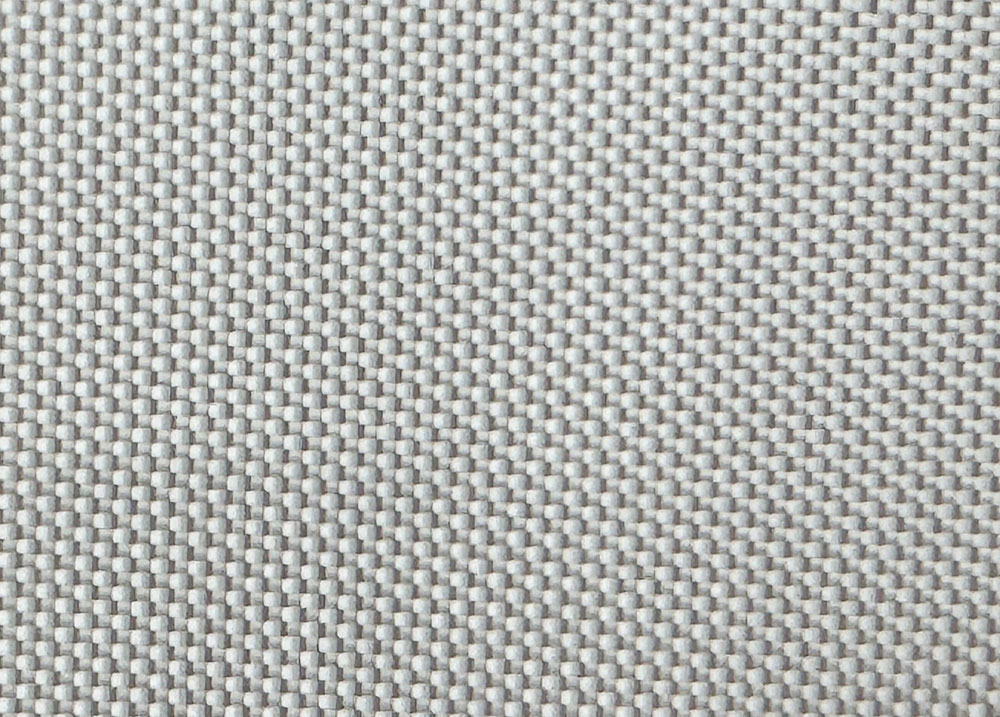

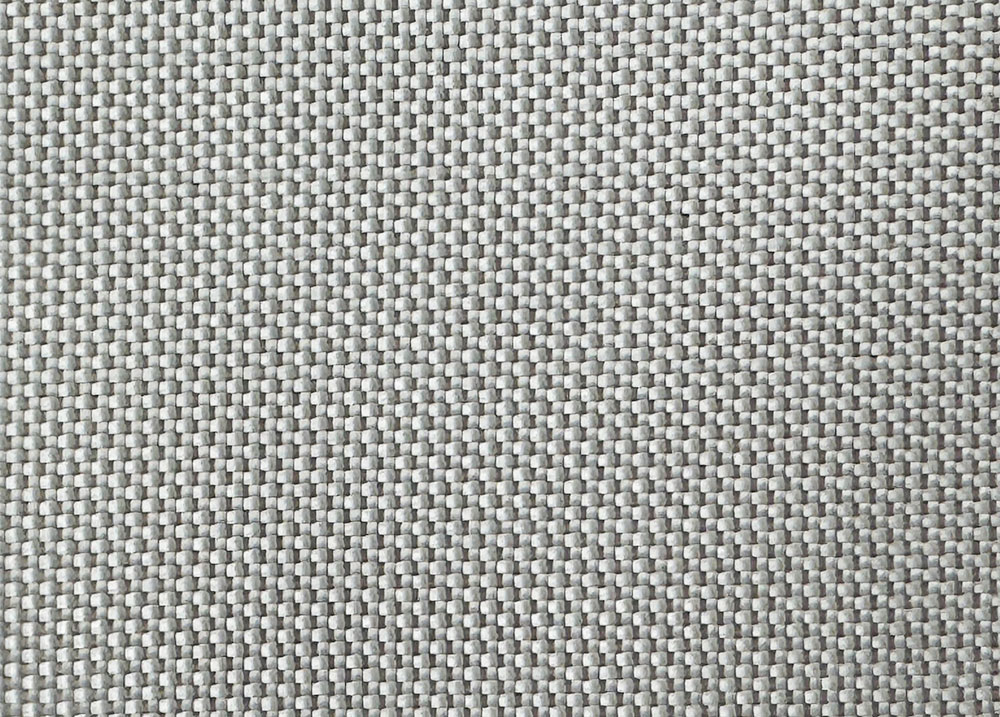

E-Glass Woven Fiberglass Fabric

· Compatible Resins: Polyester, Epoxy, Vinyl Ester

Key Features

· Industry-standard fiberglass fabric with proven performance

· High strength and durability for structural applications

· Easier to handle than chopped strand mat

· Cost-effective solution for heavy-duty reinforcement

· Uniform fiber distribution for consistent resin saturation

Applications

· Marine: Hulls, decks, bulkheads, and reinforcements

· Industrial: Tanks, structural panels, machinery components

· Aerospace: Lightweight structural reinforcements and panels

· General Composites: High-load components requiring rigidity and stability

How to Test the Performance of E-Glass Woven Fiberglass Fabric

Testing the performance of E-Glass woven fiberglass fabric typically covers mechanical, electrical, physical, and chemical properties.

Common test items and methods include:

1. Mechanical Tests

- Tensile Strength: Measures the maximum load the fabric can withstand when stretched. Usually tested according to ASTM D5035.

- Tear Strength: Assesses the fabric’s resistance to tearing, commonly tested by ASTM D1424.

- Elongation at Break: Measures the percentage elongation when the fabric breaks under tension.

- Tear Elongation: Evaluates deformation ability during tearing.

2. Physical Tests

- Fabric Weight (GSM): The weight per unit area, reflecting fabric density and thickness. Tested according to ASTM D3776.

- Thickness: Measures fabric thickness, affecting flexibility and mechanical strength.

- Dimensional Stability: Tests for shrinkage or deformation under heat or moisture conditions.

3. Electrical Tests

- Volume Resistivity: Evaluates the electrical insulation properties of the fabric, typically per ASTM D257.

- Dielectric Strength: The maximum voltage the fabric can withstand without electrical breakdown, per ASTM D149.

4. Chemical Tests

- Chemical Resistance: Exposure of the fabric to acids, alkalis, solvents, etc., followed by evaluation of property changes.

- Moisture Resistance: Tests fabric stability under high temperature and humidity.

5. Heat Resistance Tests

- Thermal Stability: Observes changes in fabric properties under elevated temperatures to assess heat resistance.

- Thermogravimetric Analysis (TGA): Measures weight loss of the material as temperature increases.

Equipment & Standards

Common testing instruments include tensile testers, thickness gauges, electrical testers, and environmental chambers.

Testing generally follows international standards such as ASTM, ISO, DIN, etc.