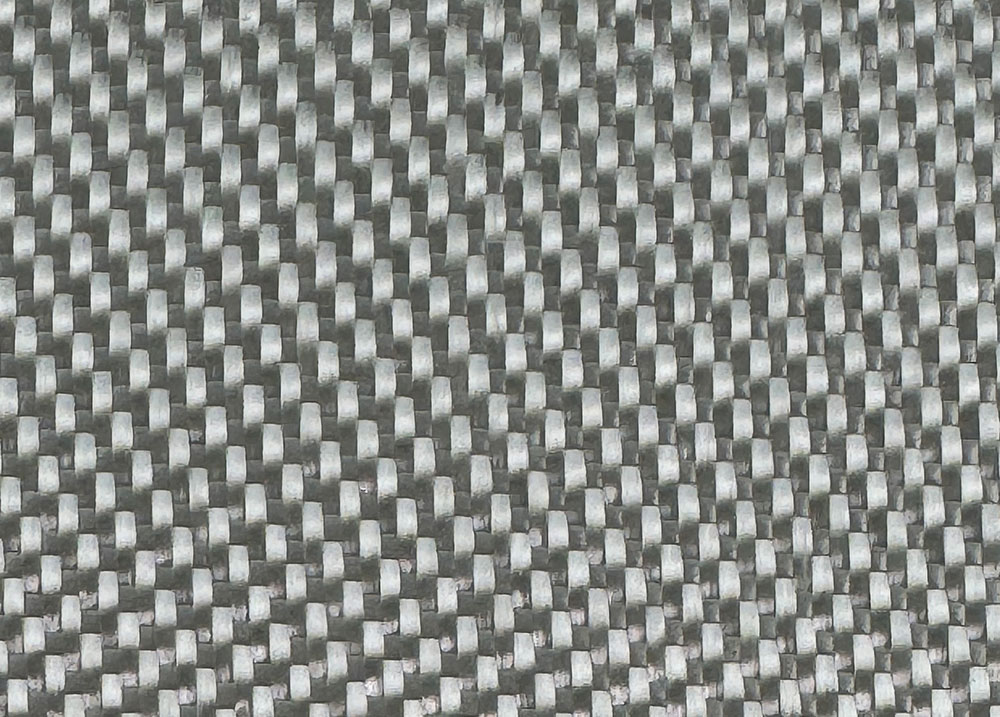

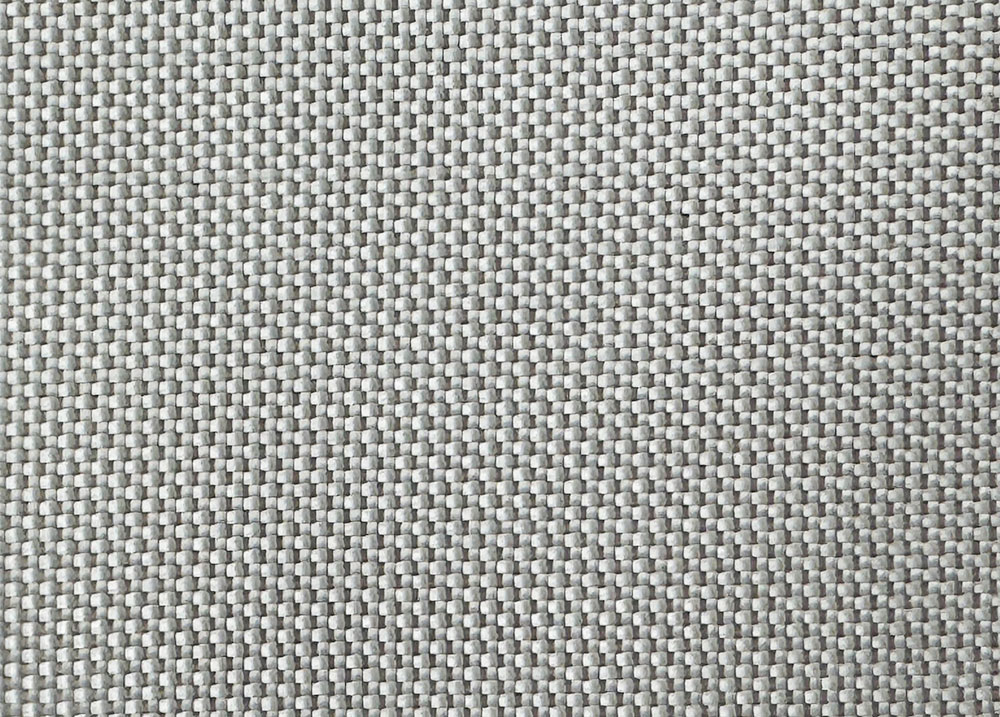

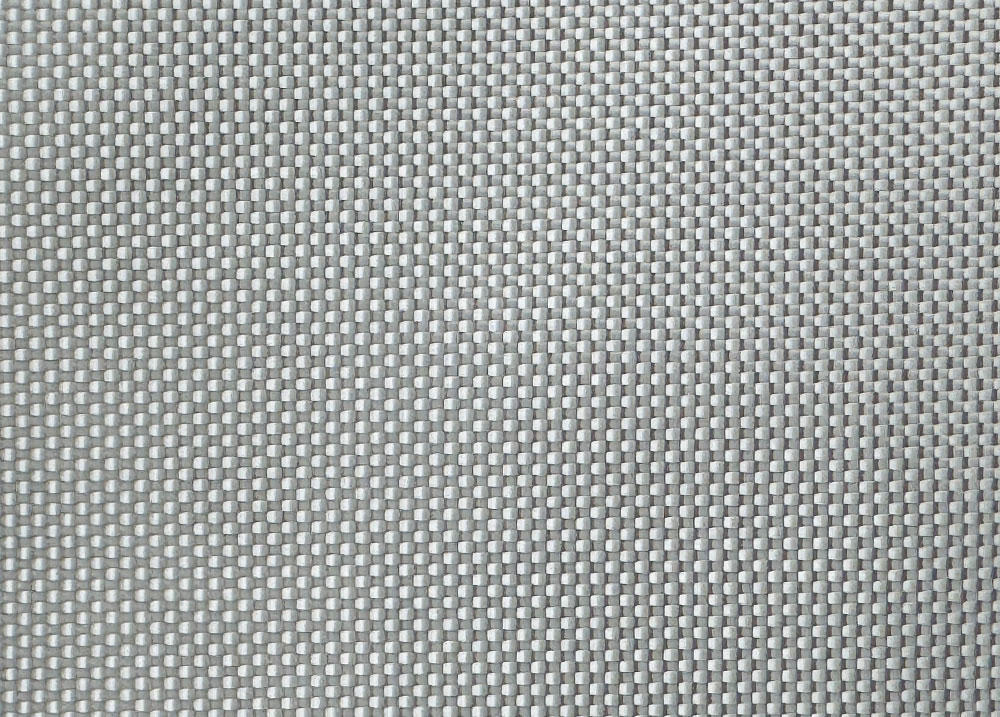

Fiberglass Twill-Style Cloth

· Compatible Resins: Polyester, Epoxy, Vinyl Ester

Key Features

· Exceptional strength and durability for heavy-duty use

· Flexible and conformable to complex shapes and contours

· Visually appealing twill pattern for aesthetic finishes

· Compatible with multiple resin systems and manufacturing methods

Applications

· Structural Reinforcement: High-strength laminates and panels

· Tooling Fixtures: Molds and patterns requiring precision and durability

· Cosmetic & Functional Parts: Applications needing both strength and visual quality

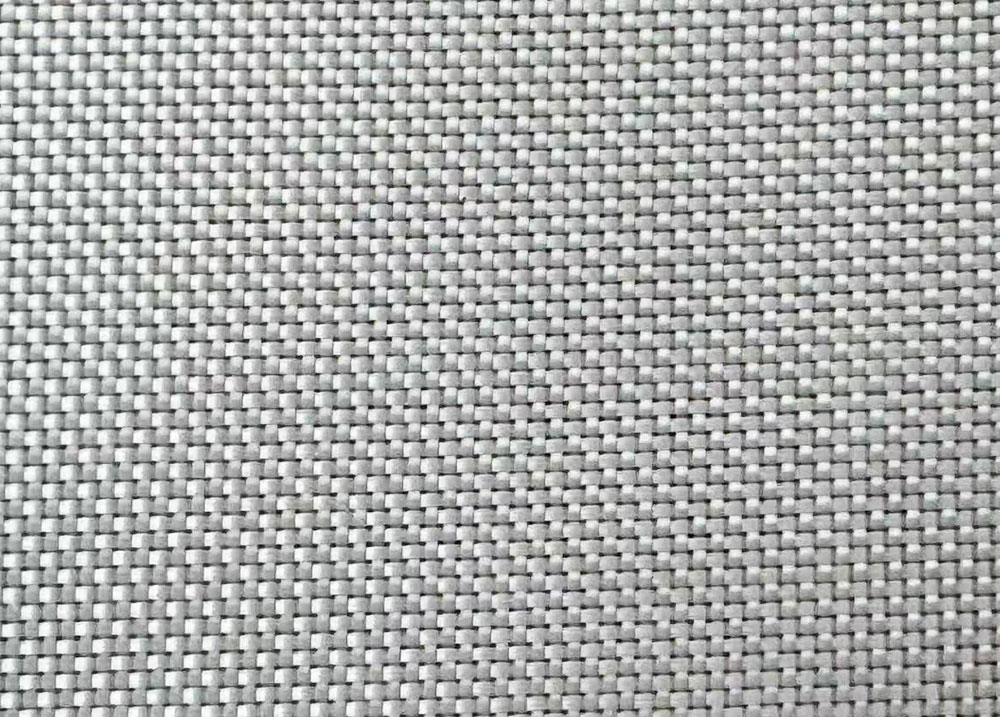

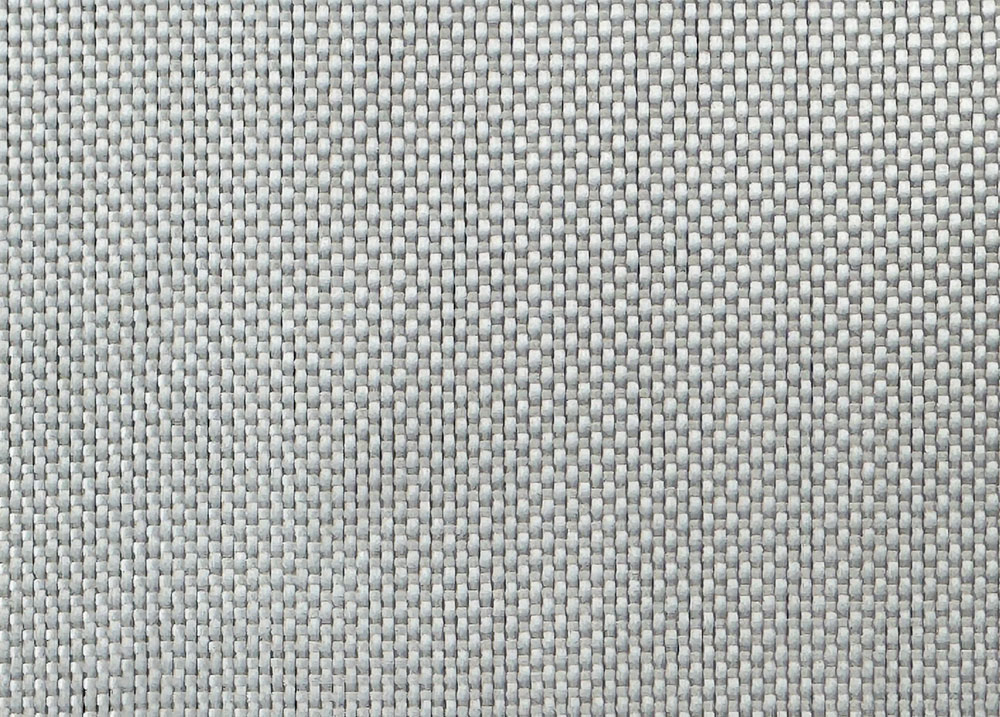

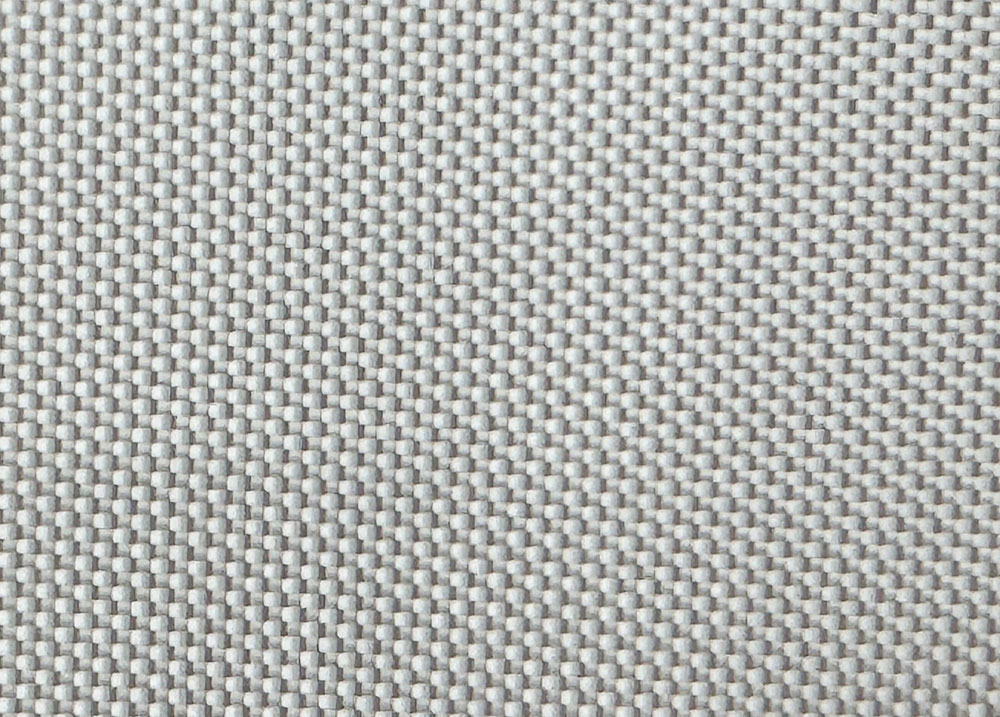

Advantages of Fiberglass Twill Weave Over Plain Weave

Better Drapability

The diagonal twill pattern allows fiberglass fabric to conform more easily to curved or complex surfaces, making it ideal for composite molding of boat hulls, car panels, and other 3D shapes.

Smoother Surface Finish

Fewer interlacings per unit area result in a smoother, glossier surface when combined with resin, improving the appearance of the final composite.

Higher Tear and Stress Resistance

Stress is distributed along the diagonal lines, giving twill weave better resistance to tearing and localized stress compared to plain weave.

Improved Flexibility

Twill weave provides a good balance of strength and flexibility, reducing brittleness and making it easier to handle during lay-up.

Enhanced Composite Performance

Easier draping and better fiber alignment often lead to more uniform resin impregnation and stronger finished composites.

Fiberglass twill weave is preferred over plain weave in applications where complex shaping, smooth surface finish, and higher tear resistance are important, while plain weave is simpler and more rigid but less adaptable to curves.