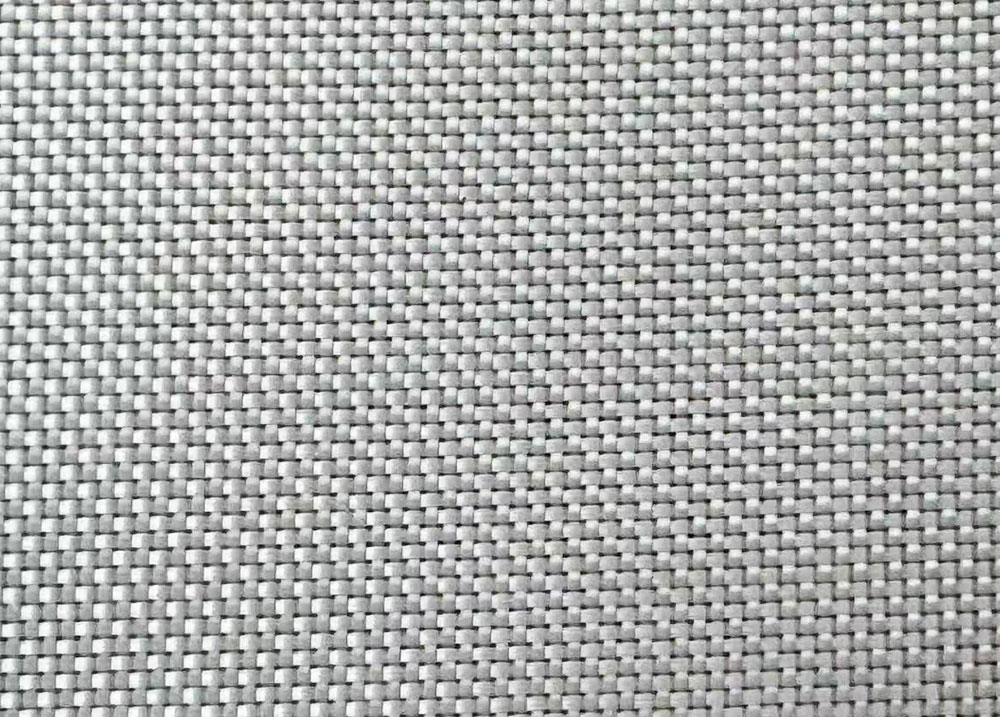

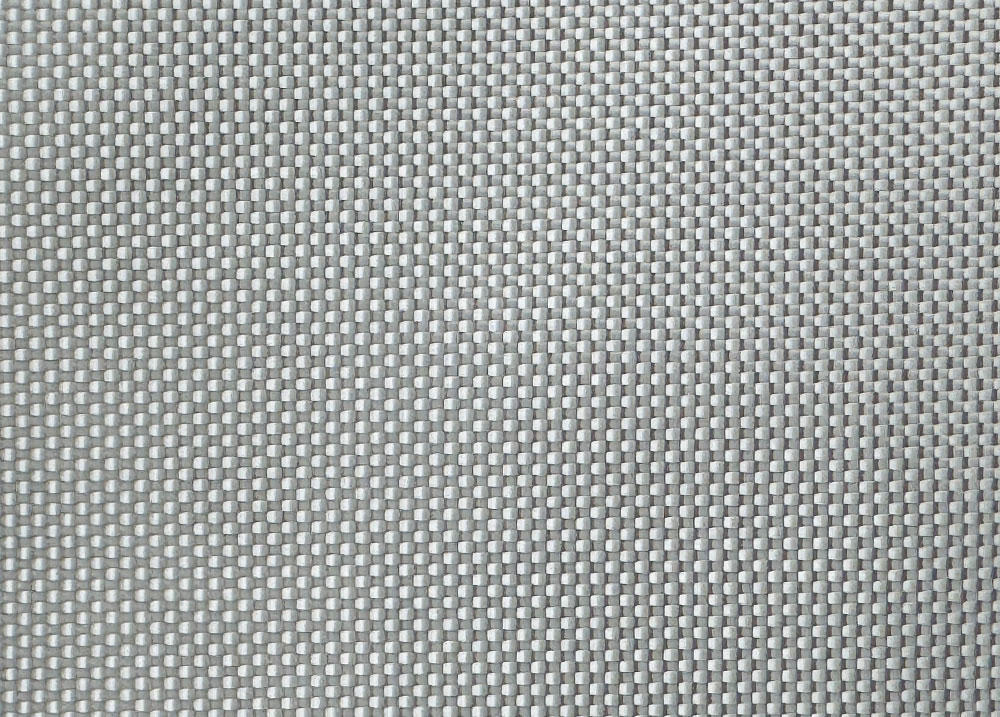

Fiberglass Fabric Roll for Boats

· Compatible Resins: Polyester, Epoxy, Vinyl Ester

Key Features

· Exceptional tensile strength, stronger than steel wire of equal diameter

· Flame and heat resistant for safe marine use

· Excellent thermal insulation properties

· Resists water, salt, and chemical corrosion

· Durable and cost-effective for large-scale marine applications

Applications

· Boat Hulls & Decks: Structural reinforcement and protection

· Marine Construction: Long-lasting performance in wet, corrosive environments

· Thermal Barriers: Insulation against engine or environmental heat

· Repairs: Heavy-duty patching and reinforcement of marine components

How is Fiberglass Fabric Roll Applied in Boat Building and Repair?

1. Hull Construction

During the boatbuilding process, fiberglass fabric is layered over molds and impregnated with resin to create a lightweight yet strong hull. Multiple layers are added in high-stress areas, ensuring the hull is durable, watertight, and impact-resistant.

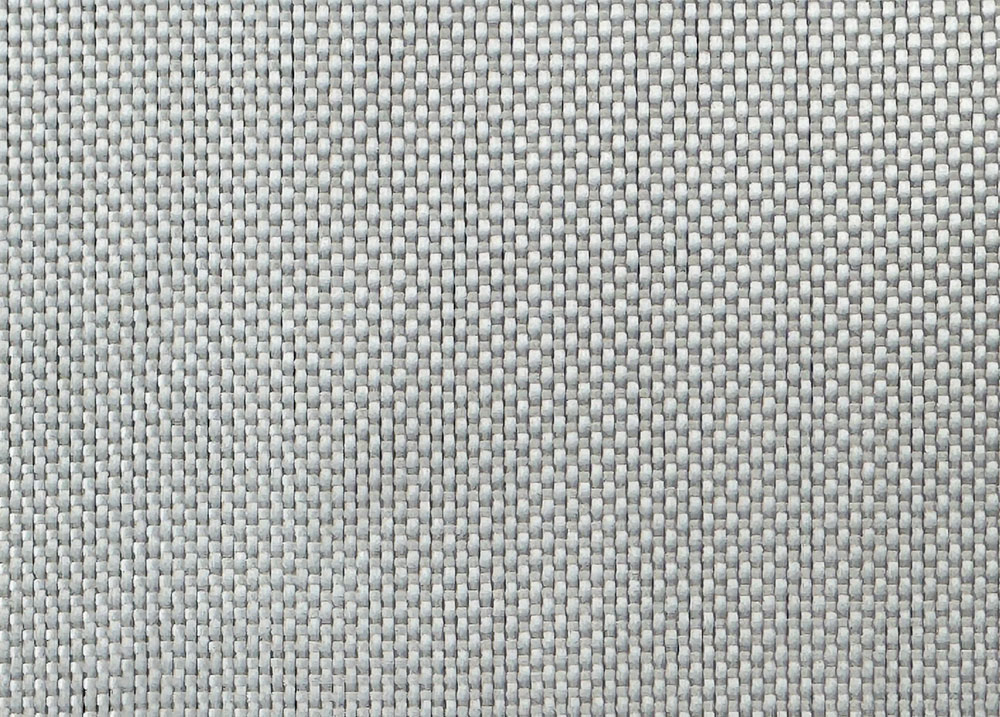

2. Structural Reinforcement

Beyond the hull, fiberglass fabric strengthens key components such as decks, bulkheads, stringers, and transoms. Heavy-duty woven fabrics are applied to reinforce areas exposed to greater loads and water pressure.

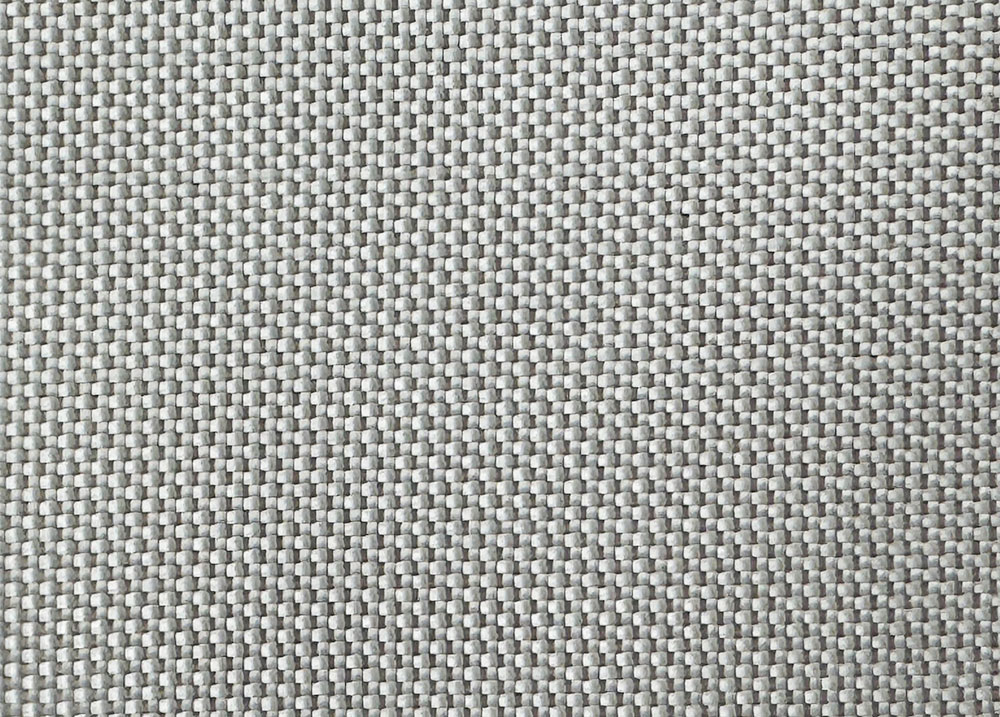

3. Repair and Maintenance

In boat repair, fiberglass cloth is commonly used to patch cracks, holes, or delaminated surfaces. When combined with resin, it restores structural integrity and waterproofing, while also acting as a protective barrier against seawater corrosion.

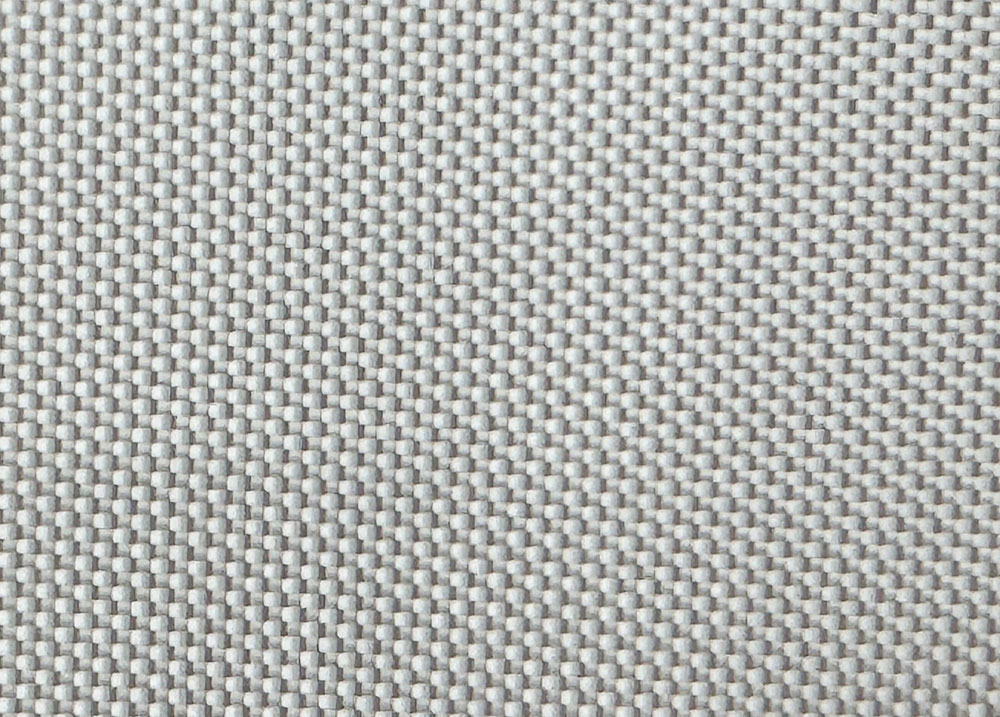

4. Surface Finishing

Fine fiberglass cloth is often used as a final layer before applying gelcoat or paint. This ensures a smooth finish, improves durability, and enhances resistance to UV exposure and weathering.

Fiberglass fabric roll is not just a material, but the backbone of modern boatbuilding. From creating robust hulls to reinforcing structures and enabling reliable repairs, it ensures boats remain strong, lightweight, and seaworthy.