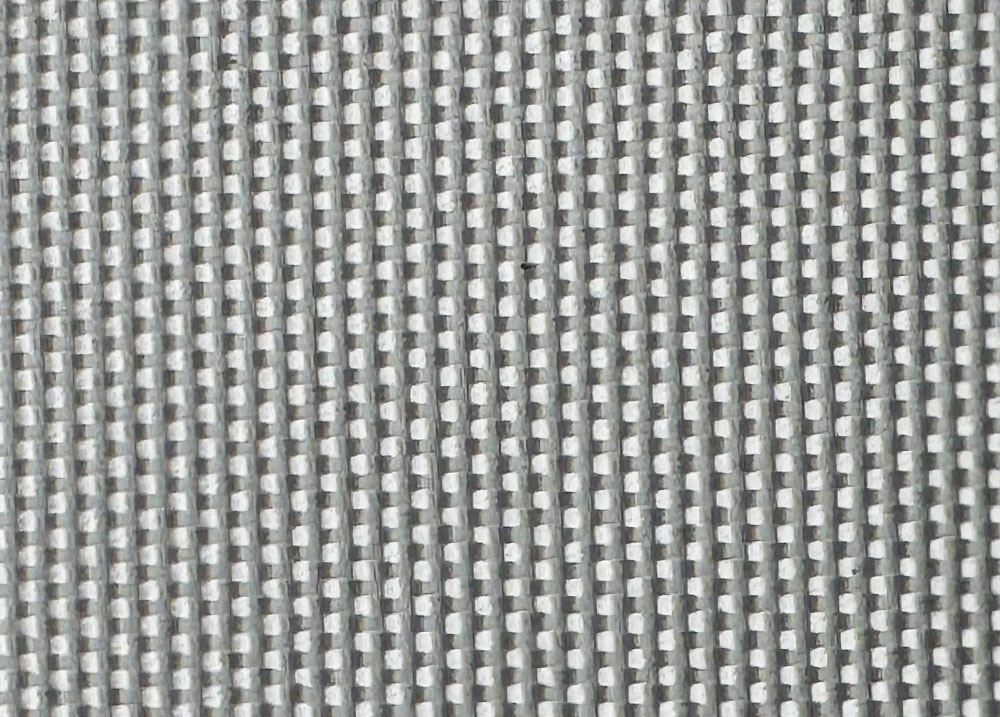

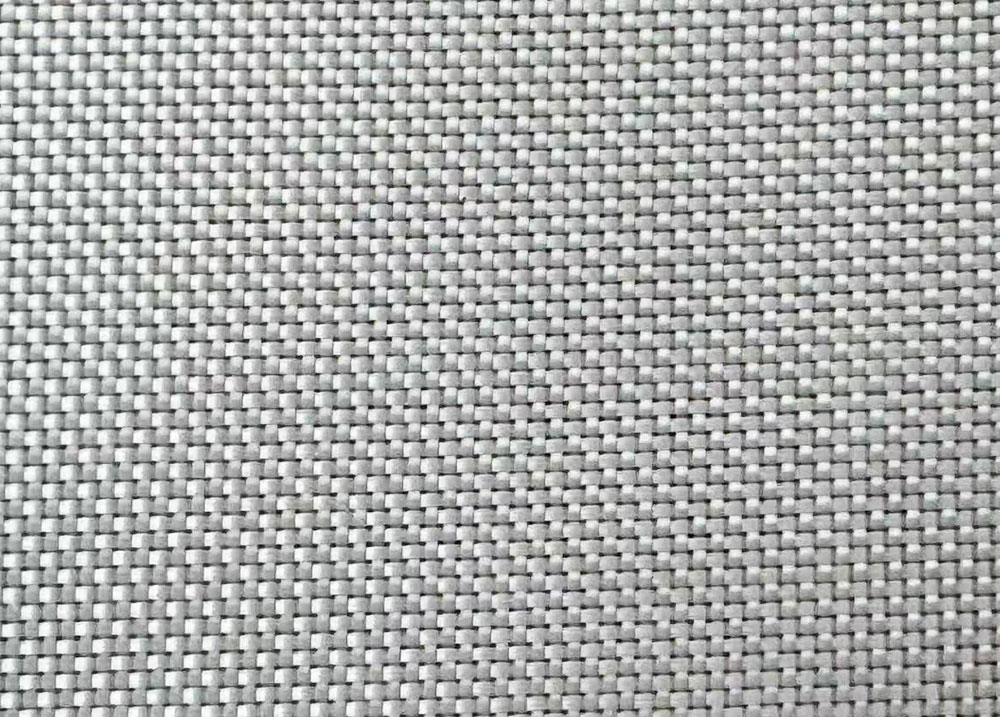

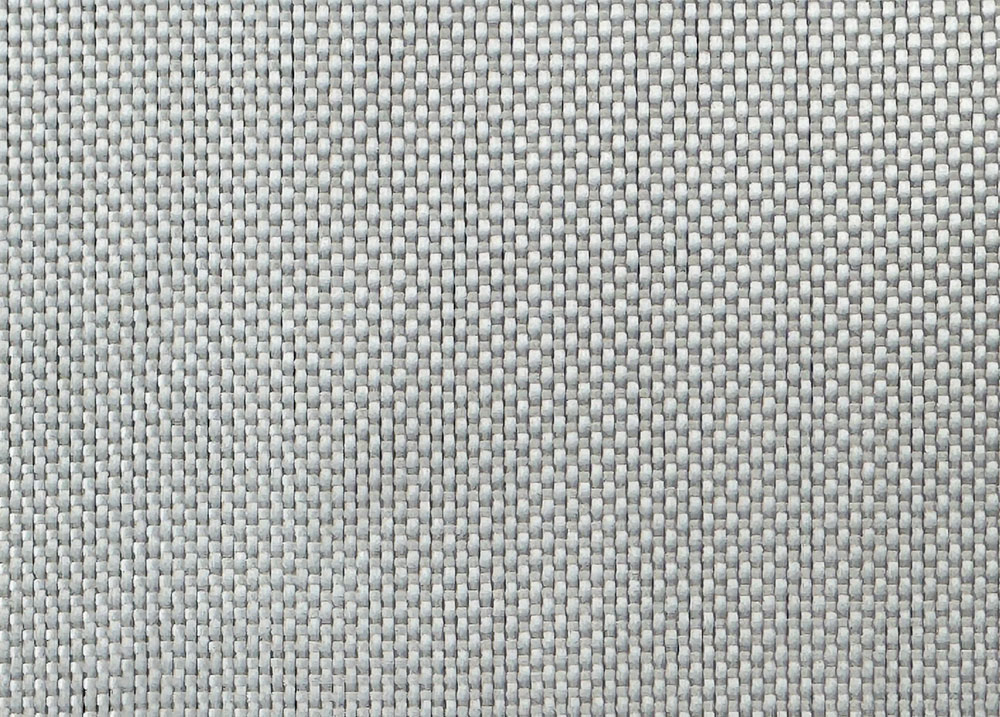

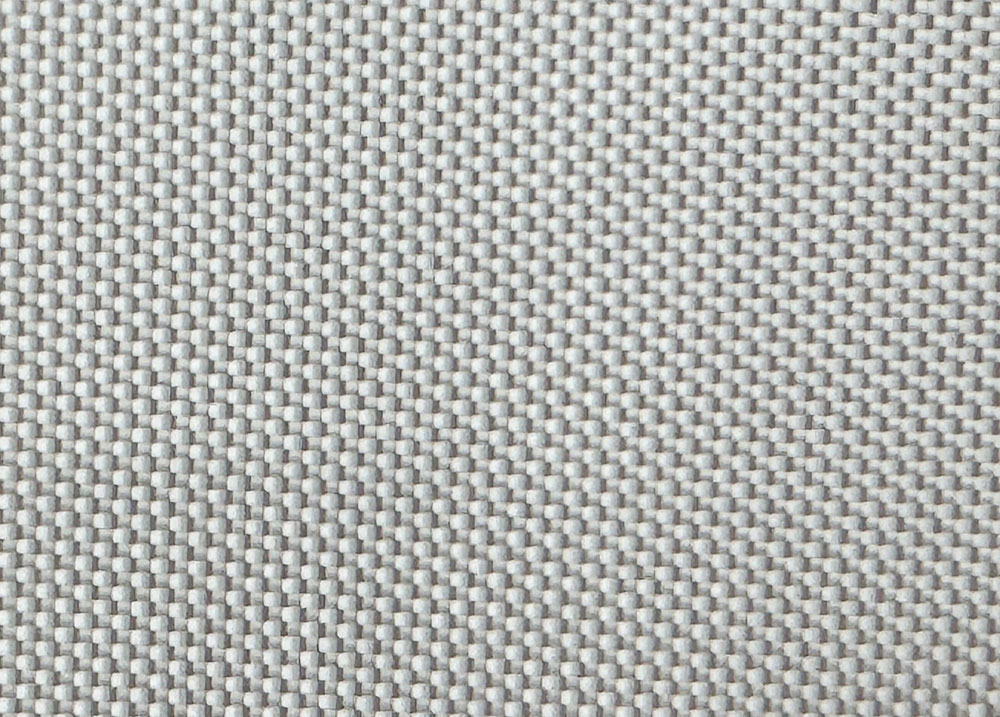

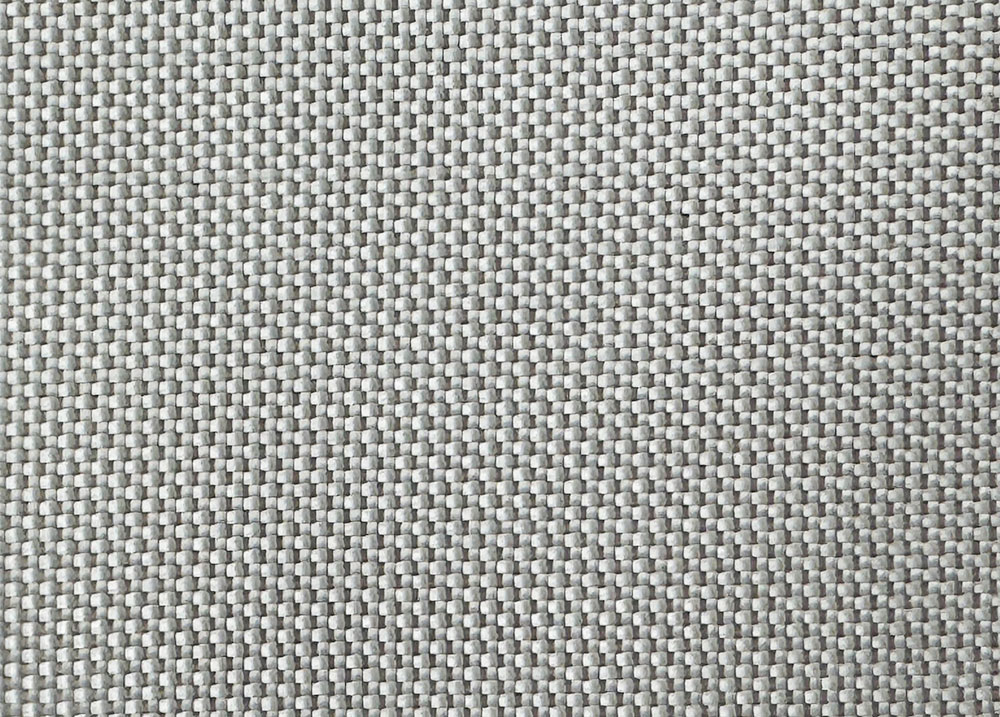

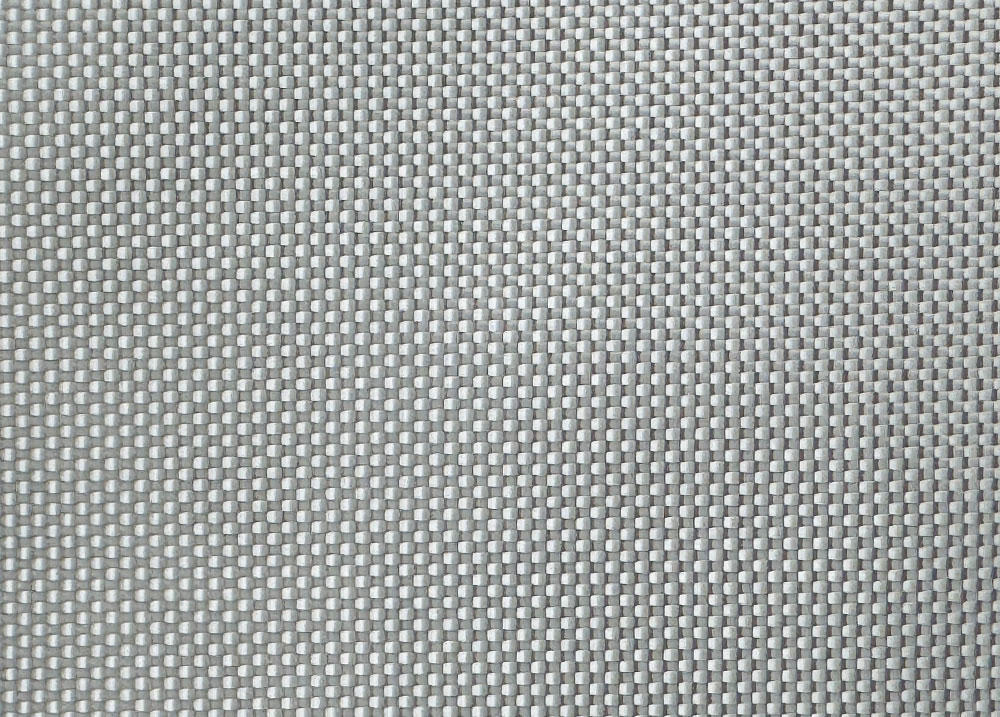

Heat Resistant Textured Woven Glass Fiber Fabric

Key Features

· Withstands extreme temperatures for thermal and fire protection

· High strength, durability, and shape stability under heat

· Excellent heat preservation and energy efficiency

· Superior coverage due to textured weave

· Low shrinkage, non-deformation performance

· Customizable with metal wires (copper, nickel, stainless steel)

Applications

· Industrial Insulation: Pipes, boilers, and high-temp equipment

· Fire Protection: Fire blankets, curtains, thermal barriers

· Filtration & Air Purification: Dust elimination and air filtering

· Sound Insulation: Industrial and commercial noise reduction

· Pipeline Wrapping: Heat and corrosion protection

· Composite Coating: Reinforcement in construction and manufacturing

The Heat-resistant Treatment on Textured Woven Glass Fiber Fabric

The heat-resistant treatment on Textured Woven Glass Fiber Fabric typically involves several processes designed to enhance the fabric’s ability to withstand high temperatures without losing its strength, shape, or performance. Here are the common treatments and methods:

1. High-Temperature Heat Setting

The fabric is subjected to controlled heating cycles at elevated temperatures (often between 300°C to 600°C) to stabilize the glass fibers and remove any residual stresses.

This process stabilizes the fabric's dimensions and texture, enhancing dimensional stability under heat.

2. Surface Coating or Impregnation

Application of heat-resistant coatings such as silicone, ceramic-based coatings, or specialized binders that increase thermal stability and protect against oxidation and thermal degradation.

Coatings can also improve abrasion resistance and reduce fiber fuzziness.

3. Chemical Treatment

Use of heat-resistant sizing agents or chemical finishes applied during or after weaving to improve fiber-matrix adhesion and thermal endurance.

These treatments help the fabric maintain integrity when exposed to thermal cycling.

4. Texturing Process with Heat Stabilization

The texturing (creating surface patterns or crimps) often involves mechanical and thermal processes to impart a 3D structure that improves flexibility and mechanical performance at high temperatures.

Heat stabilization ensures the textured shape is retained during use.

5. Post-Treatment Annealing

Sometimes the fabric undergoes annealing, a slow cooling process after heat setting, to relieve internal stresses and enhance thermal resistance.