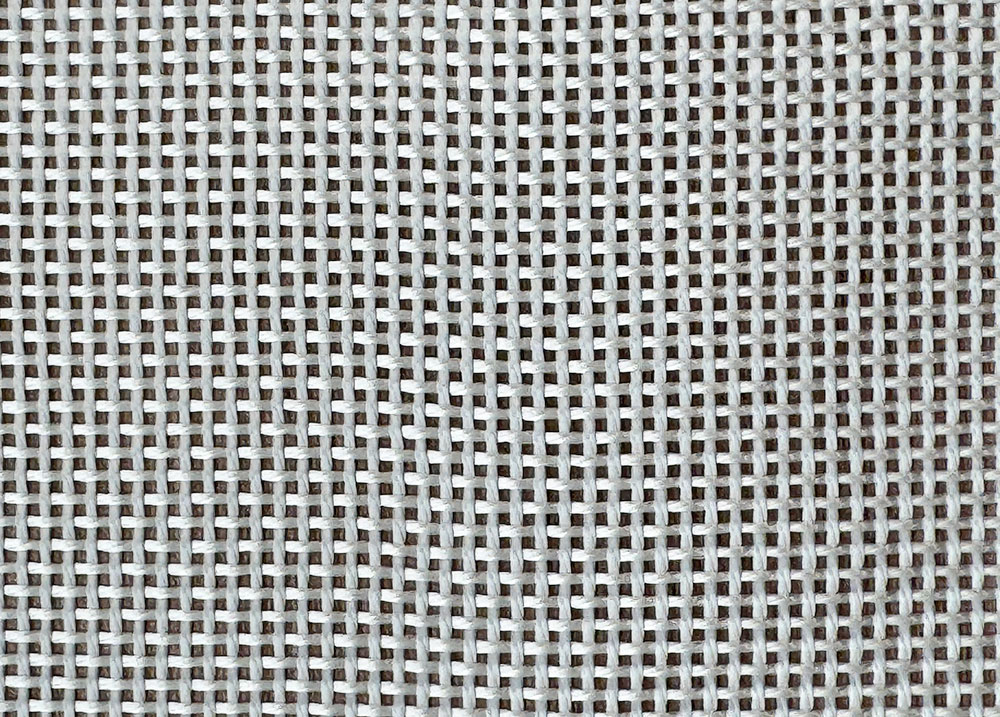

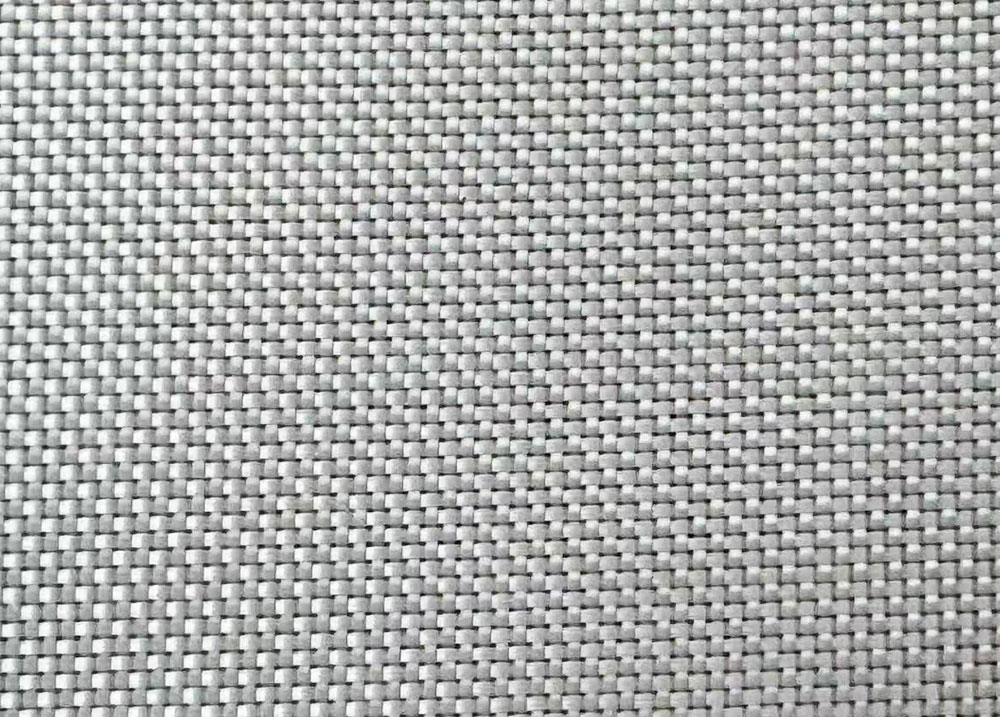

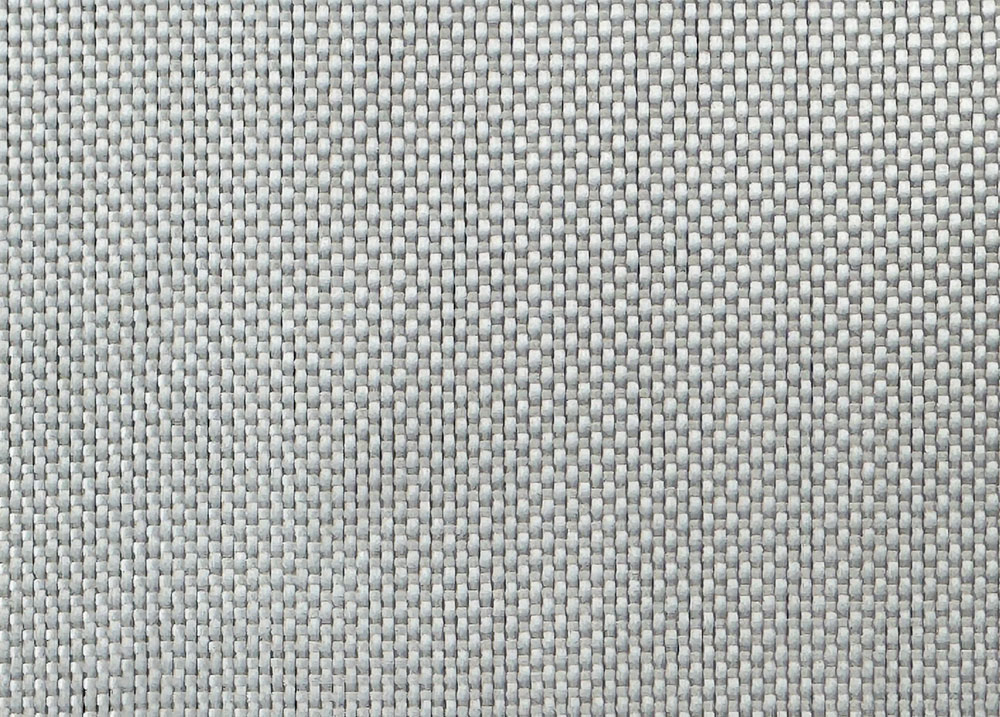

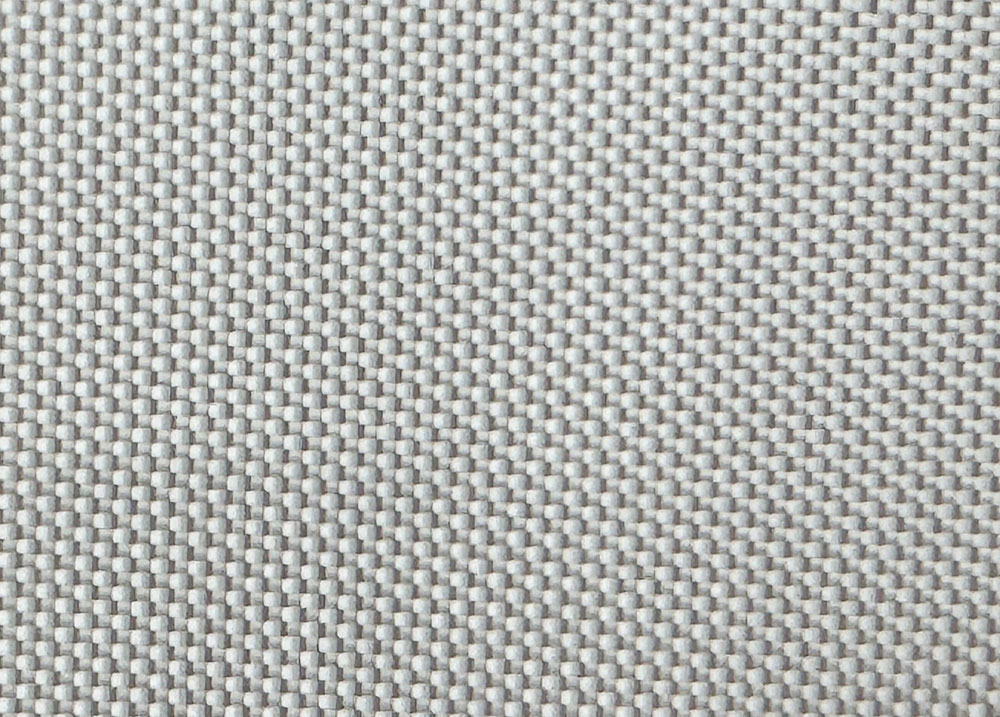

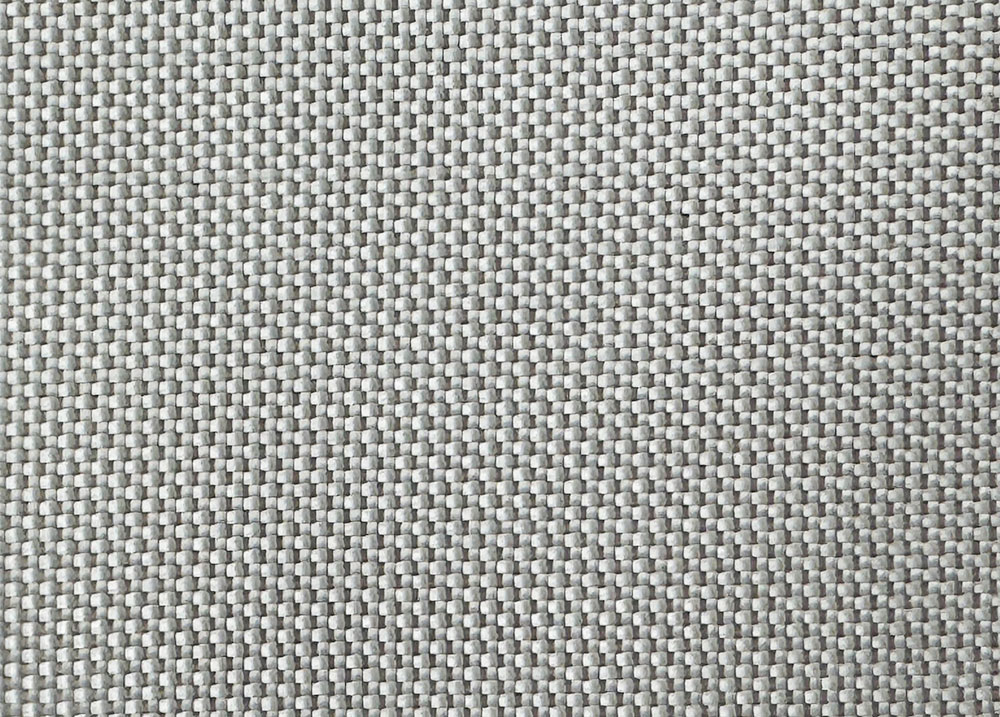

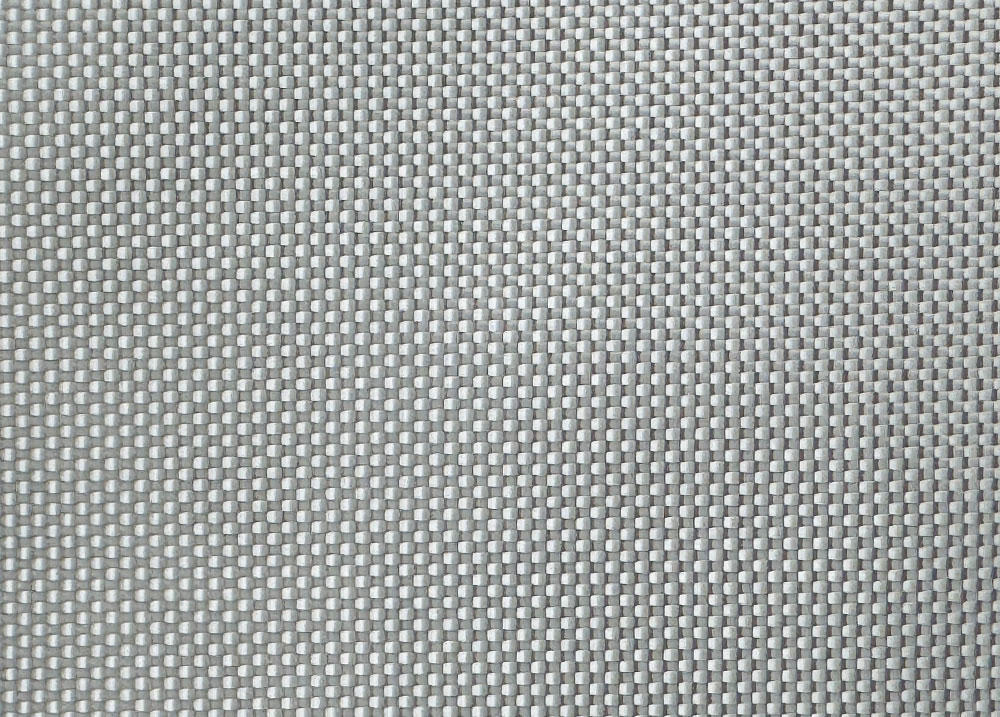

Woven Fiberglass Fabric

· Compatible Resins: Polyester, Epoxy, Vinyl Ester

Key Features

· Heavy-duty fabric for strong, rigid reinforcement

· Uniform fiber distribution for consistent mechanical performance

· Easy resin saturation for smooth, reliable lamination

· Suitable for professional and DIY use

Applications

· Marine: Hulls, decks, and structural reinforcements

· Construction: Wall panels, insulation layers, formworks

· Composite Repair: Structural repairs for fiberglass components

How can Woven Fiberglass Fabric be Corrosion-resistant?

Woven Fiberglass Fabric is naturally corrosion-resistant primarily because of the inherent properties of glass fibers, which are made from silica-based materials that do not easily react with most chemicals. Here’s how it achieves corrosion resistance:

Inorganic Glass Fibers:

Glass fibers are inorganic and chemically stable, making them highly resistant to acids, alkalis, salts, and solvents. This means the fabric itself won’t easily degrade or corrode when exposed to harsh environments.

Protective Resin Matrix:

In practical applications, woven fiberglass fabric is impregnated with resin systems like polyester, vinyl ester, or epoxy. These resins provide an additional chemical barrier that protects the fibers and the overall composite from moisture and corrosive agents.

Low Moisture Absorption:

Glass fibers absorb very little water, preventing swelling or weakening that could lead to corrosion or degradation.

Surface Treatments:

Sometimes, fiberglass fabrics receive surface treatments or coatings that enhance chemical resistance, reduce surface energy, and improve barrier properties against corrosive substances.

Thermal Stability:

Good heat resistance means the fabric maintains integrity even under elevated temperatures, which often accelerate corrosion in other materials.