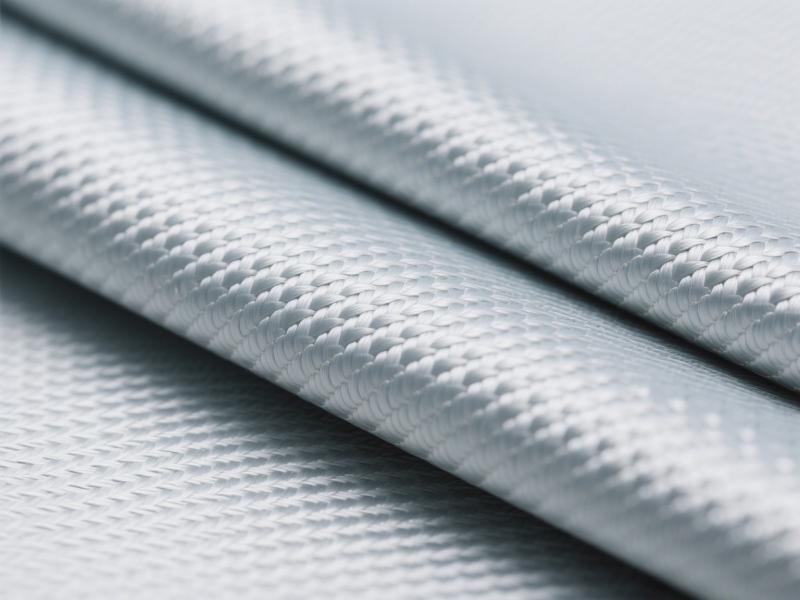

A weave of glass fibers might seem delicate at first glance, yet fiberglass reinforced cloth hides a surprising resilience beneath its seemingly fragile threads. This material, celebrated in industries from boating to automotive, owes its reputation to a unique combination of tensile strength, lightweight design, and adaptability.

Understanding what makes it strong, how it behaves under heavy loads, and how best to use it can transform both DIY projects and professional applications.

What Makes Fiberglass Cloth Strong?

Fiberglass cloth draws its strength from the fibers themselves—thin strands of glass that resist stretching while bearing tremendous tension. Each fiber is almost invisible, yet collectively they form a mesh capable of distributing stress across a surface. The weaving pattern also plays a crucial role. A plain weave offers balance in both directions, while unidirectional or twill weaves focus strength along specific lines, maximizing performance in high-stress applications.

The addition of resin—epoxy, polyester, or vinyl ester—locks these fibers in place, creating a composite that is far stronger than the cloth alone. The resin binds the fibers, prevents fraying, and allows the material to maintain shape under load. This synergy between fiber and resin is why fiberglass cloth can perform reliably in demanding environments.

Can Fiberglass Cloth Handle Heavy Loads?

A single layer of fiberglass cloth is lightweight and flexible, but not meant to support massive weight alone. However, when multiple layers are laminated with resin, the result is a stiff, strong panel capable of handling hundreds of pounds per square foot. Boats, car body panels, and structural reinforcements all rely on this layered approach.

Even in industrial settings, fiberglass composites are chosen for their impressive strength-to-weight ratio. For example, a properly laminated 6–8 layer panel can rival steel in load-bearing ability while remaining significantly lighter. Users considering heavy-duty applications should pay attention to layer count, fiber orientation, and resin type, as these factors directly influence load capacity.

How Flexible or Brittle Is Fiberglass Cloth?

Flexibility in fiberglass cloth is subtle. Unlaminated cloth drapes like fabric, easy to mold over curves, yet it can snap if pulled too hard. Laminated cloth becomes rigid, but retains some flex depending on resin type and layer thickness. This balance between stiffness and controlled flexibility allows the material to absorb impacts that might crack pure resin or brittle plastics.

Yet brittleness remains a consideration. Fiberglass doesn’t bend like metals; sudden high-impact forces can cause cracking. Layering and proper resin curing minimize this risk, ensuring that the material absorbs shock instead of fracturing outright. Understanding this property helps users design safer, longer-lasting structures.

Tips for Laminating Fiberglass Cloth

- Surface Preparation: Ensure surfaces are clean and slightly roughened for optimal adhesion.

- Resin Choice: Epoxy offers superior strength and chemical resistance, while polyester is more cost-effective for general use.

- Layer Orientation: Alternate fiber directions to balance strength across axes.

- Air Removal: Use a roller or squeegee to eliminate bubbles, preventing weak spots.

- Curing Time: Allow adequate curing under controlled temperature to maximize composite integrity.

These steps may seem simple, but attention to detail is what transforms fiberglass cloth from a fragile sheet into a robust, high-performance material. Even minor mistakes in layering or resin application can compromise the strength that users expect.

Fiberglass reinforced cloth is a quiet powerhouse: deceptively light, impressively strong, and surprisingly versatile. Its strength arises from the synergy of glass fibers and resin, while flexibility and brittleness are managed through careful layering and resin selection. Whether used in DIY projects, automotive repairs, or industrial applications, understanding these nuances allows users to leverage fiberglass cloth to its fullest potential.