Overview of Fiberglass, Aramid, and Polyester Fibers

Fiberglass, aramid, and polyester are three of the most widely used fibers in industrial and protective applications. Each of them offers unique advantages when it comes to strength, durability, and resistance to heat and chemicals.

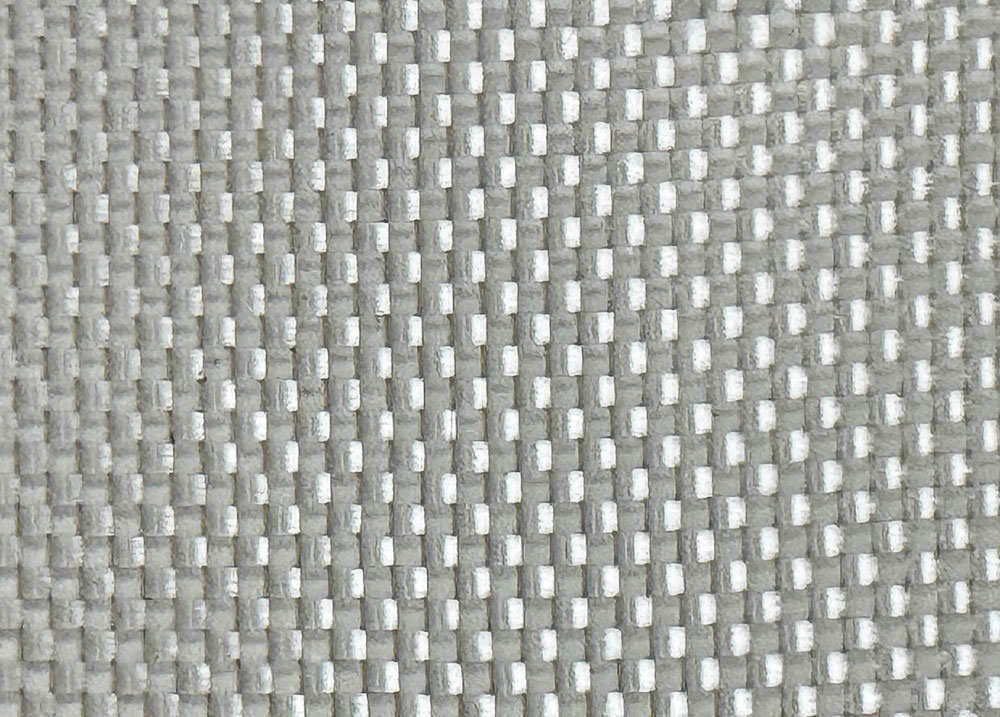

Fiberglass is made from extremely fine strands of glass, giving it excellent thermal stability and non-combustibility. It is often used in insulation materials, fire blankets, and composite reinforcements.

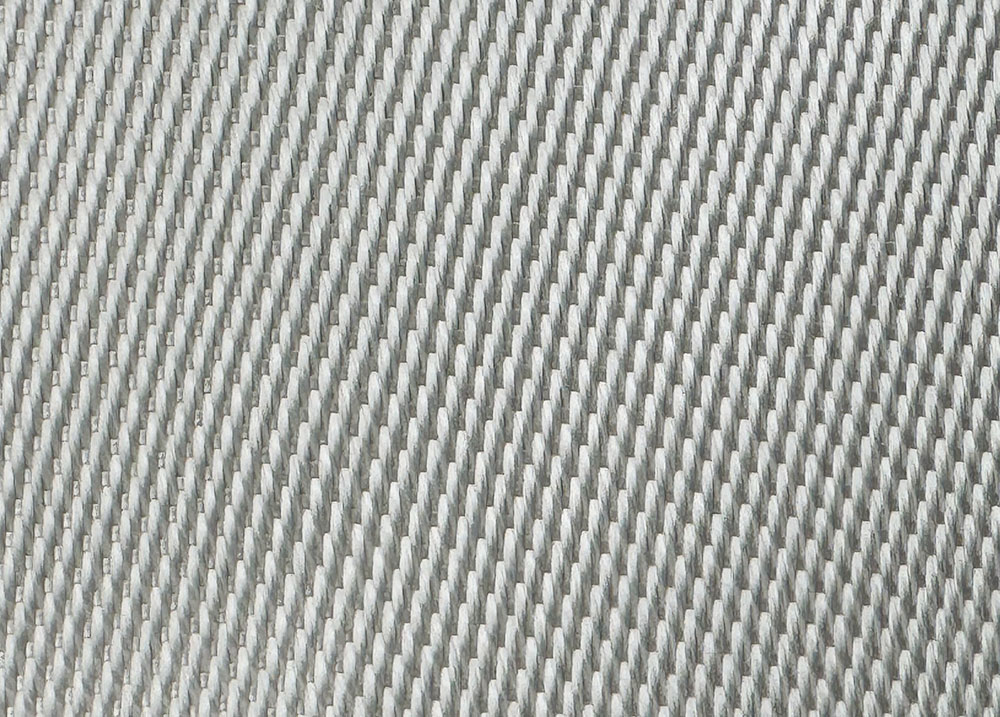

Aramid fibers, such as Kevlar or Nomex, are synthetic aromatic polyamides known for their exceptional heat and flame resistance combined with high tensile strength. They are widely applied in protective gear, aerospace components, and heat shields.

Polyester, a polymer-based synthetic fiber, stands out for its affordability, flexibility, and resistance to environmental factors like moisture and UV exposure. However, its heat resistance is moderate compared to fiberglass and aramid.

Fiberglass

How Heat Resistance Differs Among the Three Materials

When exposed to high temperatures, the molecular structure of each fiber determines how well it retains its mechanical properties.

- Fiberglass can withstand continuous exposure up to 540°C (1000°F) without melting or losing strength. It does not burn and maintains its structure even under direct flame contact.

- Aramid fibers can tolerate continuous heat up to 370°C (700°F) and can briefly resist higher peaks without melting. Instead of melting, aramid chars and maintains its integrity, which makes it ideal for fire-resistant applications.

- Polyester, on the other hand, begins to soften around 150°C (302°F) and melts at approximately 260°C (500°F). It is suitable for environments with moderate heat but not for high-temperature exposure.

These differences are critical for selecting the right material based on the expected working temperature and exposure duration.

Aramid

Impact of Heat on Strength and Durability

Prolonged exposure to heat affects not only the shape but also the mechanical strength of fibers.

- Fiberglass remains dimensionally stable and retains most of its tensile strength even after long-term high-temperature exposure. Its inorganic structure is inherently resistant to oxidation and degradation.

- Aramid performs well in thermal aging tests, maintaining strength and flexibility at high temperatures. However, it can gradually degrade when exposed to UV light or in environments with high humidity combined with heat.

- Polyester fibers tend to lose tensile strength and elasticity as temperature rises. Over time, thermal exposure accelerates polymer oxidation, leading to brittleness and reduced service life.

In summary, fiberglass leads in long-term heat endurance, aramid follows with strong thermal resilience, and polyester is best suited for lower-temperature uses.

Polyester

Other Factors to Consider

While heat resistance is crucial, practical decisions often depend on cost and physical properties.

- Fiberglass is relatively economical and offers superior heat performance, but it is heavier and less flexible, which may limit its use in lightweight or wearable applications.

- Aramid fibers are lighter and more flexible than fiberglass, making them comfortable for apparel and protective clothing. However, they are significantly more expensive.

- Polyester offers the lowest cost and best flexibility but lacks the thermal and flame resistance required for high-temperature environments.

Balancing these aspects helps manufacturers and engineers make cost-effective choices without compromising safety or performance.

Best Material for Your Application: Choosing Wisely

Selecting the ideal material depends on how heat exposure aligns with other operational requirements.

- For continuous high-temperature insulation, fiberglass is the most reliable option.

- For personal protective equipment or applications needing high strength-to-weight ratio, aramid fibers are ideal.

- For general-purpose, low-cost solutions where heat exposure is limited, polyester serves effectively.

Understanding these distinctions ensures optimal material performance and longer service life under real-world conditions.

In heat resistance comparison, fiberglass dominates in extreme temperature tolerance, aramid provides an excellent balance between heat resistance and strength, and polyester remains a cost-effective option for moderate conditions. The right choice depends on the thermal demands of your specific application and the balance between performance, weight, and budget.