When selecting materials for industrial applications, fiberglass and aramid woven fabrics often stand out as two of the most popular choices due to their exceptional strength and performance under extreme conditions. Both materials are widely used in industries such as construction, automotive, aerospace, and protective wear.

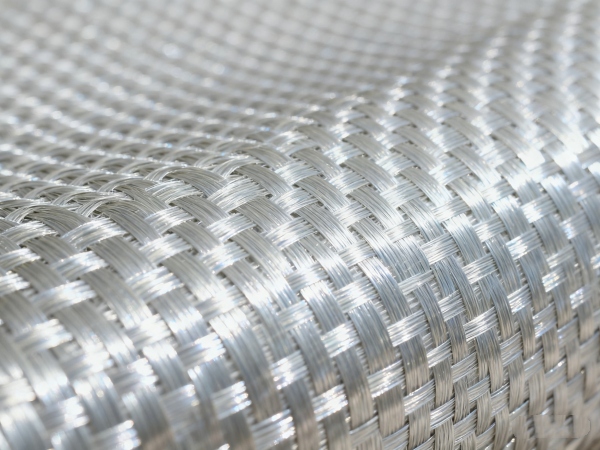

Fiberglass woven fabric is made from fine glass fibers that are woven into a fabric structure, providing impressive strength, lightweight properties, and high thermal stability. Its key feature is electrical insulation, making it useful in electrical applications and industries that require non-conductive materials.

Aramid woven fabric (commonly known as Kevlar) is derived from aromatic polyamide fibers and is best known for its outstanding strength-to-weight ratio and resistance to abrasion, heat, and chemicals. It is widely used in protective gear (e.g., bulletproof vests, fire-resistant clothing) and in industries where high performance and lightweight properties are critical.

Key Differences between Fiberglass and Aramid Fabrics

Though both fiberglass and aramid fabrics are incredibly durable, they have significant differences that impact their use:

- Strength and Toughness: Aramid fabrics are renowned for their high tensile strength and impact resistance, making them ideal for protective gear and applications requiring high durability. Fiberglass, on the other hand, is strong but tends to be more brittle and may not offer the same level of impact resistance.

- Heat Resistance: Aramid fabrics have a much higher heat resistance and can withstand temperatures of up to 400°C (752°F) without losing integrity. Fiberglass, while heat-resistant, typically starts to lose its strength at over 500°C (932°F), making aramid the better choice for extreme heat environments.

- Weight: Aramid fabrics are typically lighter and more flexible than fiberglass. This lightweight quality makes aramid fabrics ideal for use in personal protective equipment like body armor, racing suits, and industrial gloves. Fiberglass, although lightweight, is generally stiffer and may not be as comfortable for wearables or flexible applications.

- Chemical Resistance: While both fabrics offer decent resistance to many chemicals, aramid fabrics are more resistant to a wider range of chemicals and are highly resistant to abrasion. Fiberglass does well in many environments but may degrade over time with prolonged exposure to harsh chemicals.

How to Choose the Right Fabric Based on Your Application

When choosing between fiberglass and aramid fabrics, it’s crucial to understand the specific requirements of your application. Consider the following factors:

- Protective Wear: For applications such as bulletproof vests, firefighter gear, or cut-resistant gloves, aramid fabrics like Kevlar® are often the material of choice due to their abrasion resistance and high strength-to-weight ratio. Aramid is also preferred for situations where flexibility and comfort are necessary.

- Construction and Infrastructure: In industries like construction or aerospace, where strength and durability are essential, fiberglass woven fabric is widely used. It’s ideal for insulation, structural reinforcement, and non-conductive applications.

- Automotive: Both materials are used in automotive applications, but aramid is more commonly used in brake linings, clutch plates, and high-performance tires due to its heat resistance and strength. Fiberglass is used in areas like car body reinforcement and insulation due to its lightweight and high tensile strength.

Comparison: Strength, Durability, and Heat Resistance

To make an informed decision, it's important to evaluate the performance metrics of both materials:

- Strength: Aramid fabric excels in impact resistance and abrasion resistance. It has a higher strength-to-weight ratio than fiberglass, making it suitable for applications where lightweight but durable materials are needed.

- Durability: Fiberglass fabrics are generally more durable in structural applications due to their higher resistance to compression and pressure. However, aramid has superior flexibility and longer-term durability in high-performance, high-risk scenarios (e.g., firefighting, law enforcement).

- Heat Resistance: As mentioned, aramid fabrics can withstand temperatures of up to 400°C, making them a top choice for high-heat applications like protective suits and fireproof gear. Fiberglass is suitable for high-temperature environments but tends to perform better in electrical applications and insulation.

Cost Considerations: Which Fabric Offers Better Value?

While both fiberglass and aramid fabrics offer high performance, their costs vary:

Aramid fabrics tend to be more expensive due to the complex manufacturing process and specialized chemical treatments involved. They are best suited for high-value applications, such as military gear, ballistic vests, and extreme heat gear.

Fiberglass is generally less expensive, making it a more cost-effective option for applications that don’t require the extreme durability and strength of aramid. It’s ideal for insulation, reinforced fabrics, and automotive parts where cost and performance need to be balanced.

Is One Fabric More Eco-Friendly?

Both fiberglass and aramid fabrics are synthetic materials, and neither is fully biodegradable. However, there are notable differences in their environmental impacts:

Fiberglass is recyclable but may release small amounts of harmful particles during production or disposal. The material is relatively low-impact compared to other industrial materials when managed properly.

Aramid fabrics like Kevlar® are difficult to recycle, and their production process involves the use of toxic chemicals. However, they have a longer lifespan, which can reduce the environmental impact in the long run by minimizing the need for replacements.