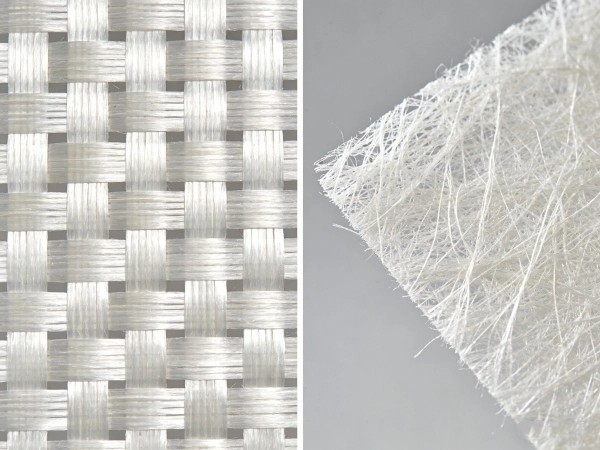

Woven vs. Nonwoven Fiberglass: What are They?

Woven fiberglass is produced by interlacing yarns of glass fiber in a controlled pattern, such as plain weave, twill weave, or satin weave. The resulting fabric has a stable, uniform structure with high tensile strength and consistent mechanical behavior. Woven fiberglass is commonly used in applications where dimensional stability, high strength-to-weight ratio, and controlled drape are required.

Nonwoven fiberglass, also known as fiberglass mat or chopped strand mat, is made by randomly distributing glass fibers and bonding them together through chemical binder, thermal bonding, or mechanical entanglement. The resulting mat is isotropic in nature, meaning it offers more uniform strength in all directions, but typically has lower tensile strength compared to woven fabrics. Nonwoven fiberglass is widely used in bulk molding compounds (BMC), sheet molding compounds (SMC), roofing materials, and general-purpose reinforcement.

The fundamental difference is that woven fiberglass relies on yarn interlacing, while nonwoven fiberglass relies on fiber randomization and bonding. This distinction drives performance differences such as resin wet-out, impact resistance, and handling characteristics.

How are Woven and Nonwoven Fiberglass Made?

Woven Fiberglass Manufacturing

The production of woven fiberglass starts with glass fiber strands that are bundled into rovings. These rovings are then processed into yarns through twisting and sizing. The yarns are fed into a weaving loom, where warp and weft yarns are interlaced to form a fabric. The weave pattern determines key properties:

• Plain weave: offers balanced strength and stability

• Twill weave: provides better drape and higher tensile strength

• Satin weave: offers smoother surface finish and improved conformability

After weaving, the fabric may undergo additional finishing processes such as coating, sizing, or surface treatment to enhance compatibility with resin systems.

Nonwoven Fiberglass Manufacturing

Nonwoven fiberglass production begins with chopped glass fibers that are spread into a random mat. Common manufacturing methods include:

• Chopped strand mat (CSM): randomly oriented fibers held together by binder

• Needle-punched mat: fibers mechanically entangled for improved integrity

• Stitched mat: fibers stitched with polyester or glass yarn to improve handling

• Wet-laid mat: fibers formed in water and bonded with resin or binder

Nonwoven mats can be engineered to different weights, thicknesses, and binder contents. These parameters directly influence resin uptake, mechanical performance, and ease of processing.

What are the Main Performance Differences?

Tensile Strength and Structural Stability

Woven fiberglass fabrics typically provide higher tensile strength, flexural strength, and impact resistance due to the continuous yarn structure. The interlaced yarns create a strong load-bearing network, which performs well under tension and repeated stress.

Nonwoven fiberglass mats generally have lower tensile strength but can offer better isotropic properties because the fibers are distributed randomly. This makes them suitable for applications where uniform strength distribution is more important than peak tensile performance.

Resin Compatibility and Wet-Out

One of the most important factors in composite manufacturing is resin wet-out. Woven fiberglass tends to have lower resin absorption and may require careful resin infusion to avoid dry spots. The tight weave can impede resin flow if not properly managed, especially in hand lay-up or vacuum infusion processes.

Nonwoven fiberglass mats, due to their open fiber structure, typically exhibit excellent resin wet-out and faster impregnation. This makes them a preferred reinforcement in bulk molding compounds, polyester resin systems, and general-purpose laminates.

Dimensional Stability and Creep Resistance

Woven fiberglass provides superior dimensional stability and lower creep under sustained load. The structured weave resists deformation, which is critical for high-performance composites used in aerospace, marine, and automotive structural components.

Nonwoven fiberglass may experience more dimensional change under load because the fibers are not locked into a structured network. However, nonwoven mats can be stabilized through binder systems and hybrid constructions.

Surface Finish and Aesthetics

Woven fiberglass generally delivers a more uniform and aesthetically pleasing surface finish, especially when used in clear resin systems. The visible weave pattern can also be desirable for decorative composites.

Nonwoven fiberglass surfaces are typically rougher and require additional surface layers or gel coats for high-quality appearance.

Where is Each Type Used?

Common Applications of Woven Fiberglass

Woven fiberglass is widely used in applications requiring high strength and controlled mechanical performance, such as:

• Marine hulls and decks

• Aerospace and defense composites

• Automotive body panels and reinforcements

• Wind turbine blades and structural components

• Sporting goods and high-performance equipment

• Common Applications of Nonwoven Fiberglass

Nonwoven fiberglass is commonly used where cost-efficiency and ease of processing are priorities:

• Roofing materials and insulation

• SMC/BMC automotive parts

• General-purpose composite laminates

• Pipe and tank reinforcement

• Filtration and industrial applications

Nonwoven fiberglass is particularly advantageous in large-volume manufacturing and products that require consistent thickness and quick resin infusion.

How to Choose between Woven and Nonwoven Fiberglass?

Choosing the right fiberglass reinforcement requires evaluating several key factors:

Performance Requirements

If high tensile strength, impact resistance, and dimensional stability are critical, woven fiberglass is the preferred choice.

Processing Method

For hand lay-up, vacuum infusion, or resin transfer molding (RTM), woven fabrics may require more controlled resin flow. Nonwoven mats are often easier to wet-out and process.

Cost and Production Volume

Nonwoven fiberglass is typically more cost-effective for high-volume, lower-performance applications. Woven fiberglass is costlier but provides higher performance and better aesthetics.

End-Use Environment

Consider environmental exposure, UV resistance, moisture, and chemical compatibility. Both woven and nonwoven fiberglass can be engineered with suitable resin systems and coatings.

Composite Design Considerations

For multi-layer laminates, hybrid reinforcement using both woven fabric and nonwoven mat can optimize strength, stiffness, and cost. Many composite manufacturers combine materials to achieve balanced performance.