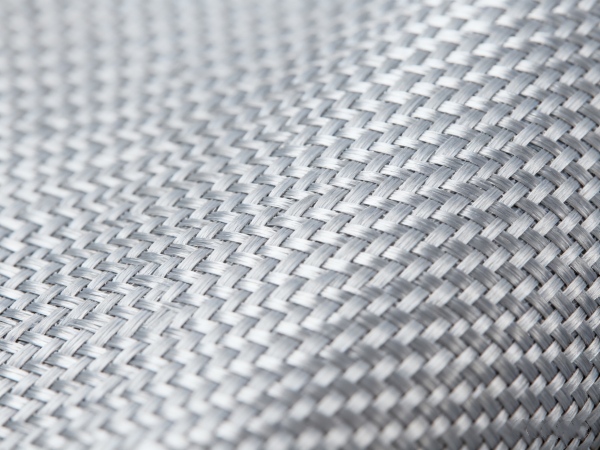

When you have spent years walking through noisy workshops, chemical plants, or construction sites, you start to notice which materials survive the harshest environments and which ones fail quickly. One of the most reliable options I have seen across different industries is fiberglass woven fabric. It combines strength, versatility, and cost-effectiveness, making it a go-to solution for engineers, procurement teams, and technicians. Let’s explore its biggest benefits in detail.

Strong and Durable Material for Long-Term Use

Durability is the number-one concern for any industrial buyer. From my experience, fiberglass woven fabric holds up under stress far better than many conventional textiles. The woven construction adds dimensional stability, which means it resists stretching, tearing, and surface wear.

For example, in shipbuilding, fiberglass woven fabric is often layered into hull structures. Despite constant exposure to water pressure and mechanical impact, it maintains integrity for years. This reliability reduces maintenance downtime and long-term repair costs.

High Temperature Resistance for Industrial Processes

Many industries operate in environments that exceed the limits of ordinary fabrics. Fiberglass woven fabric is a standout because it maintains its mechanical properties even at very high temperatures, often up to 550°C (and in special coatings, beyond that).

Take welding workshops as an example: fiberglass woven curtains are commonly used as heat shields to protect workers and equipment. In power plants, it can be applied as insulation wraps for turbines, where metal casings alone aren’t enough. These real-world cases show how the fabric’s temperature tolerance translates directly into workplace safety.

Lightweight but Reliable Performance

A surprising advantage of fiberglass woven fabric is how lightweight it is compared to its strength. Carrying, installing, or repositioning rolls doesn’t require heavy equipment. For site workers, this translates into easier handling and faster installation.

Think of it this way: a single roll can be carried by two people without strain, yet once in place it delivers the rigidity and tensile strength required for reinforcement in construction or automotive components. This “light but strong” combination makes it unique.

Corrosion and Chemical Resistance

If your work involves chemicals, acids, or moisture, you need a material that doesn’t degrade easily. Fiberglass woven fabric offers excellent resistance to corrosion and many aggressive chemicals.

Here are a few typical uses I’ve seen in the field:

1. Chemical storage tanks lined with fiberglass fabric remain intact even when exposed to acidic vapors.

2. Cooling towers in humid environments use fiberglass laminates to prevent rust issues that plague steel.

3. Marine docks employ fiberglass sheets as reinforcement, avoiding the corrosion that saltwater causes on metal.

This property ensures the fabric holds up where metals would corrode and ordinary fabrics would quickly break down.

Easy to Cut, Shape, and Install

Industrial buyers often ask me, “Is it difficult to work with?” My answer is always no—fiberglass woven fabric is surprisingly user-friendly.

Its advantages during installation include:

1. Custom shaping – it can be cut into panels, sheets, or rolls without losing stability.

2. Layering flexibility – multiple layers can be laminated for higher strength.

3. Quick adjustments – workers can trim or adapt pieces on-site with basic tools.

This adaptability reduces labor costs and ensures the fabric fits a wide range of industrial designs.

Wide Range of Industrial Applications

The real beauty of fiberglass woven fabric lies in its versatility. I’ve seen it applied in so many different industries that it feels almost universal. Common applications include:

1. Construction – reinforcement for concrete, wall panels, roofing sheets.

2. Shipbuilding – laminates for hulls and decks.

3. Automotive – heat shields, body reinforcement.

4. Aerospace – lightweight composites for structural parts.

5. Everyday products – surfboards, sports equipment, even protective clothing.

For industrial users, this wide application base means one material can meet multiple project requirements, simplifying procurement and reducing supply chain complexity.

After years of working with different industrial textiles, I can say that fiberglass woven fabric consistently proves its value. It is durable, heat-resistant, lightweight, corrosion-proof, easy to work with, and versatile across industries. For buyers looking to invest in materials that deliver both performance and efficiency, this fabric is an option that rarely disappoints.