Fiberglass fabric is widely used in composites, insulation, marine applications, and industrial reinforcement. Yet, many buyers still struggle to understand two essential specifications that directly affect performance: GSM (grams per square meter) and weave type. Knowing these two parameters makes it easier to compare products, choose the right grade, and avoid quality issues in future applications.

What does GSM Mean?

GSM stands for Grams per Square Meter, which represents the weight of the fiberglass fabric per unit area.

It is one of the most important indicators of fabric density and is commonly used across technical textiles.

What GSM Tells You

- Fiber content: Higher GSM usually means more glass fiber, resulting in stronger reinforcement.

- Fabric strength: Higher GSM fabrics provide greater tensile strength and impact resistance.

- Stiffness level: Lightweight GSM is more flexible, while heavier GSM is stiffer.

Suitability for specific applications: For example, low-GSM fiberglass is suitable for surface layers, while high-GSM fiberglass is used in structural layers.

Typical GSM Ranges in Fiberglass

- 100–200 GSM: Very light, used for surface finishing, small repairs, and flexible laminates.

- 200–400 GSM: Common for general reinforcement, mold building, and lightweight structural parts.

- 400–800 GSM: Strong and durable, ideal for boat building, automotive panels, and industrial composite structures.

- 800–1200 GSM+: Very heavy fabrics used where maximum strength and stiffness are required.

GSM is Different from Thickness

Many new buyers assume GSM equals thickness, but the two indicators are not the same.

GSM Measures Weight

1. It tells you how much material is used in a square meter.

2. Thickness Measures Physical Height

3. It indicates how “thick” the fabric layer is in millimeters.

Why They Are Not Equal

1. Because fabric thickness is influenced by:

2. Weave type (plain, twill, satin)

Yarn diameter

1. Tension and compression during manufacturing

2. Resin absorption behavior

For example:

A 300 GSM plain weave can be thicker but less smooth than a 300 GSM twill weave, even though both have the same GSM. A tightly woven fabric may have higher GSM but appear thinner. GSM should be used as the primary reference for weight and strength, while thickness helps evaluate formability and layering.

Popular GSM Options and Their Uses

Different applications require different layers of fiberglass reinforcement. Below are the most commonly used GSM categories in the market.

200 GSM – Light Reinforcement

- Smooth finishing layers

- Repairs for cracks and minor damage

- Flexible laminates

- RC hobby parts, lightweight covers

300–400 GSM – General Purpose

- Boat hull skins

- Automotive aftermarket parts

- DIY composite projects

- Mold creation and repair

This is the most widely used range due to its balance between weight and strength.

600 GSM – Medium to Heavy Reinforcement

- Structural layers in marine and industrial products

- Wind turbine blade manufacturing

- Protective equipment panels

- Reinforcement of weak spots in composite molds

800–1200 GSM – Heavy Structural Layers

- Industrial composite structures

- High-load components

- Thick laminates requiring maximum rigidity

- Base layers in mold construction

Choosing the right GSM ensures the final composite meets strength, stiffness, and durability requirements.

Several Weave Types of Fiberglass Fabrics

The weave pattern determines how the glass yarns interlace, directly influencing flexibility, strength, drape, and appearance.

Plain Weave

- Yarns interlace one over, one under

- Excellent dimensional stability

- Suitable for flat surfaces

- Moderate strength and low drape

Twill Weave

- Diagonal pattern formed by yarn offset

- Greater flexibility than plain weave

- Better drape for curved surfaces

- Higher impact resistance

Satin Weave

- Long floating yarns produce a smooth surface

- Superior drape and conformability

- Ideal for complex 3D shapes

- Slightly less stable than plain weave

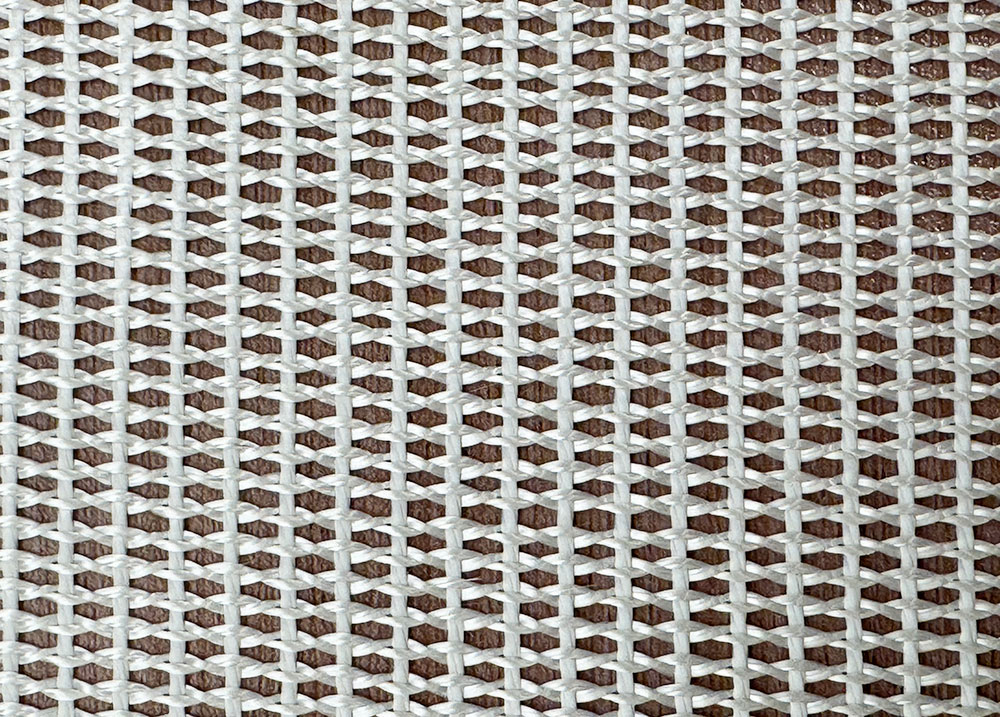

Leno Weave

- Warp yarns twisted around the weft

- Prevents fraying and distortion

- Common in open-mesh fiberglass fabrics

Different weaves cater to different industries depending on whether they prioritize formability, stability, or structural strength.

How Different Weaves Affect Performance

The weave determines how the fabric behaves during processing and in the final composite.

1. Strength and Load Distribution

- Plain weave distributes load evenly but has lower drape.

- Twill weave offers higher tensile strength and impact resistance.

- Satin weave provides a smooth finish with excellent load distribution over curved surfaces.

2. Flexibility and Drape

Satin > Twill > Plain

Complex molds benefit from fabrics that easily conform to corners and curves.

3. Resin Absorption

Plain weave absorbs resin more uniformly.

Twill and satin fabrics may require controlled resin application to prevent pooling due to larger gaps.

4. Surface Finish

Satin weave creates the smoothest finish, ideal for visible parts.

Plain weave leaves a more textured surface.

5. Dimensional Stability

Plain weave is the most stable.

Twill and satin weaves shift more easily, requiring careful handling.