Fiberglass woven fabrics are essential materials in industries ranging from construction to aerospace. Their exceptional strength, thermal resistance, and durability make them a popular choice for applications demanding high performance. However, not all fiberglass fabrics are created equal, and multiple factors can significantly affect their properties.

This article explores the critical factors that influence the performance of fiberglass woven fabric, providing insights for engineers, manufacturers, and designers.

How Does Fiber Type Affect Strength?

Fiber type is one of the most fundamental factors determining the performance of fiberglass woven fabrics. Fiberglass comes in several varieties, including E-glass, S-glass, and C-glass, each with unique properties:

• E-glass is the most common type, offering excellent electrical insulation and moderate tensile strength, making it suitable for general industrial applications.

• S-glass provides higher tensile strength and superior impact resistance, ideal for aerospace and ballistic applications.

• C-glass exhibits chemical resistance, making it suitable for harsh environments with exposure to acids or alkalis.

In addition to glass type, the filament diameter also influences performance. Finer filaments improve fabric flexibility and smoothness, while thicker filaments enhance tensile strength. Manufacturers must carefully select fiber types based on the intended application to balance strength, durability, and cost.

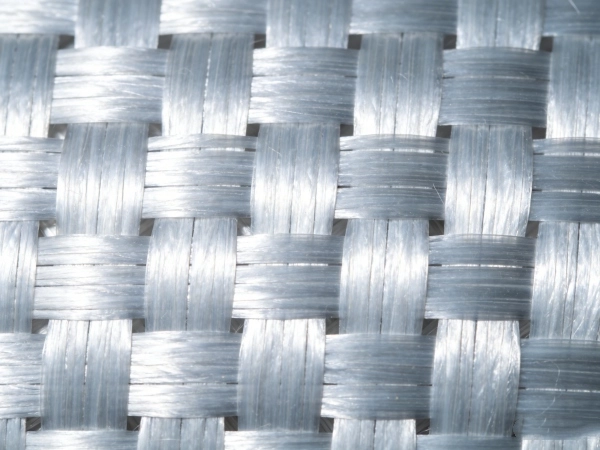

What Role Do Weave Patterns Play?

Weave patterns define how fibers interlace, affecting load distribution, flexibility, and overall mechanical performance. Common weave patterns in fiberglass fabrics include plain weave, twill weave, and satin weave:

• Plain weave provides uniform strength in both warp and weft directions, making it suitable for general reinforcement.

• Twill weave offers higher drapability and better conformability to complex shapes while maintaining significant strength.

• Satin weave produces smooth surfaces, which are ideal for lamination and composite applications requiring a high-quality finish.

Selecting the appropriate weave pattern is crucial, as it influences not only mechanical properties but also resin impregnation efficiency and surface smoothness for composite fabrication.

How Do Environmental Factors Impact Performance?

Fiberglass woven fabrics are often exposed to challenging environmental conditions, and these factors can affect both short-term and long-term performance:

• Moisture and humidity can slightly reduce tensile strength and affect dimensional stability if fabrics are not properly treated.

• Chemical exposure, including acids, alkalis, and solvents, can degrade untreated fibers over time.

• UV radiation and thermal cycling can cause surface embrittlement and weaken the fabric structure if protective coatings are absent.

Understanding the environmental impact is essential for applications like marine construction, outdoor insulation, and chemical containment, where fabrics must maintain consistent performance under demanding conditions.

Which Tests Measure Fabric Performance?

Performance testing ensures that fiberglass woven fabrics meet the required specifications for each application. Key tests include:

• Tensile testing measures strength and elongation under load, providing critical data for structural applications.

• Tear resistance evaluates how well the fabric resists propagation of cuts or punctures.

Thermal and fire resistance tests ensure fabrics can withstand high temperatures without losing structural integrity.

Advanced testing also includes resin compatibility and fatigue testing, which help engineers predict long-term performance in composite structures. Incorporating rigorous testing during production ensures high-quality fabrics that meet industry standards.

How Can Coatings and Innovations Enhance Performance?

Modern fiberglass fabrics often receive coatings, laminations, or hybrid treatments to enhance performance beyond their natural properties:

• Sizing agents improve adhesion between fibers and resin, enhancing composite strength.

• Chemical coatings increase resistance to moisture, acids, and alkalis.

• Hybrid fabrics, combining fiberglass with aramid or carbon fibers, offer superior tensile strength and impact resistance.

Emerging innovations, such as nanocoatings and advanced weaving techniques, continue to expand the potential applications of fiberglass fabrics, allowing engineers to achieve lightweight, strong, and durable materials for cutting-edge projects.