What is Fiberglass Woven Mesh Fabric?

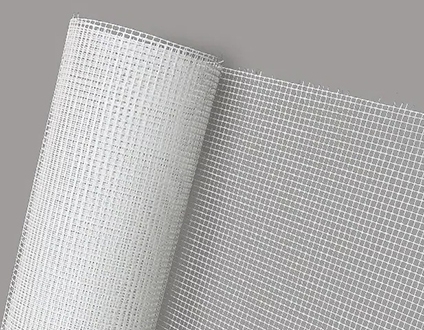

Fiberglass woven mesh fabric is a high-strength material made by weaving continuous glass fibers into a grid or mesh pattern. These fibers are coated with an alkali-resistant (AR) resin, which protects them from corrosion and degradation, especially when exposed to cement and other alkaline materials commonly used in construction. This coating ensures durability, flexibility, and long-lasting performance. The mesh is lightweight, non-corrosive, and resistant to heat and chemicals, making it a versatile reinforcement material.

Because of its unique properties, fiberglass mesh fabric is widely used to reinforce surfaces and prevent cracking in plaster, concrete, and other building materials. Its open-grid design allows for excellent adhesion with coatings and mortars, providing enhanced strength without adding excessive weight.

What can Fiberglass Mesh be Used for?

Fiberglass mesh has a broad range of applications, primarily in the construction and renovation industries.

Some of the most common uses include:

Wall Reinforcement: It is commonly embedded in plaster or cement-based coatings to strengthen interior and exterior walls, preventing cracks caused by temperature changes or structural movement.

External Insulation and Finish Systems (EIFS): Fiberglass mesh is an essential component in EIFS to improve impact resistance and durability of insulation layers.

Drywall Joint Reinforcement: It is used to reinforce drywall seams and joints, ensuring smooth finishes and preventing cracks.

Tile Installation: It can be applied beneath tiles to provide additional structural support and reduce the risk of tile cracking or detachment.

Waterproofing Systems: Fiberglass mesh enhances the strength and flexibility of waterproof membranes, especially on roofs and balconies.

Floor Reinforcement: It is also used in floor screeds and concrete overlays to reduce shrinkage cracks.

These diverse applications demonstrate why fiberglass mesh has become a staple material in modern construction, helping extend the lifespan of buildings and improve structural integrity.

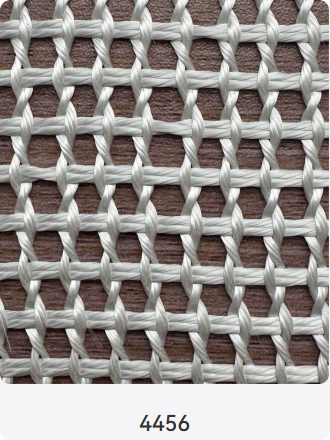

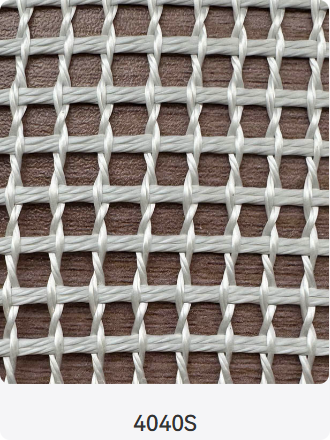

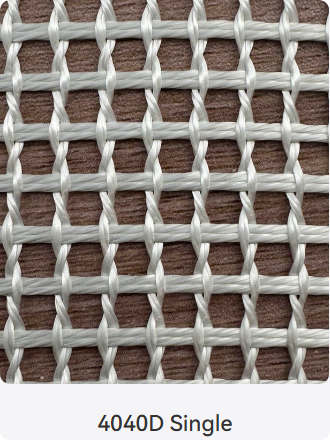

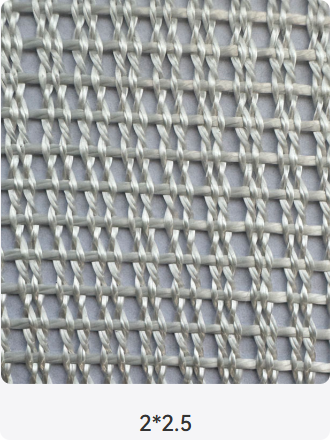

Some Specifications of Fiberglass Mesh

When choosing fiberglass mesh, understanding its specifications is crucial to ensure it meets your project requirements.

Key specifications include:

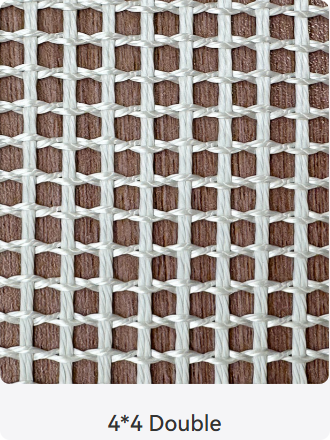

Mesh Size: Typically ranges from 4×4 mm to 10×10 mm. Smaller mesh sizes offer more reinforcement but may add weight.

Weight (GSM - grams per square meter): Common weights vary from 40 GSM to 180 GSM. Higher GSM indicates thicker, stronger mesh.

Width and Length: Rolls can come in various widths, commonly 1 meter or 1.2 meters wide, with lengths from 50 to 100 meters or customized sizes.

Alkali Resistance: A critical property indicating how well the mesh resists degradation in alkaline environments. High-quality fiberglass mesh usually has an alkali resistance index above 90%.

Color: Most fiberglass mesh is white or off-white, sometimes green or yellow, depending on the coating.

Tensile Strength: This measures the mesh’s resistance to pulling forces, crucial for reinforcement effectiveness.

Choosing the right combination of these factors depends on the application, desired strength, and installation conditions.

Fiberglass Mesh vs. Other Alternatives

Fiberglass mesh offers several advantages compared to other reinforcement materials such as metal mesh, plastic mesh, or non-woven fabrics:

Corrosion Resistance: Unlike metal mesh, fiberglass mesh does not rust or corrode, making it ideal for wet or alkaline environments.

Lightweight and Flexible: It is easier to handle and install than heavier metal alternatives.

Alkali Resistant: Special coatings protect fiberglass mesh from degradation caused by cement and lime, which is a weakness for many plastic meshes.

Cost-Effective: While not always the cheapest option, fiberglass mesh provides excellent durability and performance for the price.

Strong Adhesion: Its woven structure allows better bonding with cement, plaster, and adhesives compared to some plastic or non-woven meshes.

These advantages make fiberglass mesh a preferred choice for many construction professionals seeking long-term reliability and ease of use.

Our Products

Click the pictures to browse it!

Some Installation Tips for You

Proper installation of fiberglass mesh is essential to maximize its reinforcing benefits.

Here are some practical tips:

Clean Surface: Ensure the surface is clean, dry, and free of dust or loose particles before applying the mesh.

Overlap Edges: Overlap mesh sheets by at least 5-10 cm to ensure continuous reinforcement and avoid weak points.

Embed Fully: Embed the mesh fully in a compatible adhesive, mortar, or plaster layer to avoid wrinkles or air pockets.

Avoid Excessive Stretching: Do not overstretch the mesh during installation to prevent distortion of the grid.

Protect From UV: If exposed to sunlight for prolonged periods before finishing, choose UV-resistant mesh or cover it promptly.

Use Suitable Tools: A flat trowel or roller can help press the mesh evenly into the substrate for uniform coverage.

Following these guidelines will help prevent cracking, delamination, and premature failures, ensuring your fiberglass mesh reinforcement performs optimally.